HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Hinges are indispensable parts in furniture, doors and windows, industrial equipment. Whether it is the smoothness of the cabinet door switch, or the stability of heavy machinery, are directly affected by the hinge material. The two most common options on the market are zinc alloy hinges and stainless steel hinges. This article will analyze the differences between these two materials in detail, to help you make a wise choice according to the actual needs.

the advantages and disadvantages of zinc alloy hinge analysis

What are the characteristics of zinc alloy material?

- Low melting point (about 380°C), suitable for die-casting molding

- Liquid fluidity is good, can create complex shapes

- Natural oxidation of the surface to form a protective layer, there is a certain ability to prevent rust

Advantages of zinc alloy hinges

- Inexpensive: 30%-50% lower than stainless steel, suitable for projects with limited budgets

- Light weight: 40% lighter than the same size stainless steel, reduce the burden of the door panel

- Variety of appearance: support plating, painting and other processing, can be made into gold, black and other fashionable colors

- Easy processing: suitable for mass production, short delivery cycle

Disadvantages of zinc alloy hinges

- Easy to corrode: rust spots may appear in 2-3 years in humid environment (e.g. bathroom).

- Not resistant to low temperature: -10°C or below may be brittle and fracture.

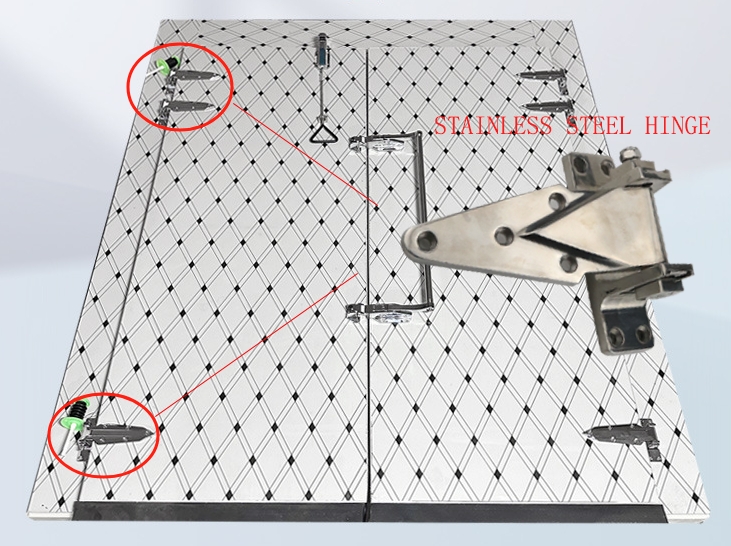

the comprehensive analysis of stainless steel hinges

The core characteristics of stainless steel

- Containing more than 10.5% chromium, forming a self-repairing oxide layer

- Common models 304 (daily use) and 316 (high corrosive environment)

- Hardness up to HRC28-32, more than 2 times of zinc alloy.

Advantages of stainless steel hinge

- Super load-bearing: single hinge can carry more than 50kg.

- Rustproof and durable: can be used in coastal areas for more than 10 years without rusting.

- High temperature resistance: can work under 200°C environment for a long time.

- Maintenance-free: basically no lubrication and maintenance

Disadvantages of stainless steel hinges

- Higher price: the cost is 2-3 times of zinc alloy.

- Difficult to process: requires specialized equipment such as laser cutting

- Heavy weight: may need to reinforce the installation substrate

zinc alloy hinge vs stainless steel hinge: 6 key comparison

| Comparison dimension | Zinc alloy hinge | Stainless steel hinge |

|---|---|---|

| Cost | ¥5-15USD/pc | ¥15-50USD/pc |

| Load capacity | ≤20kg | ≥50kg |

| Rustproof performance | Indoor dry environment can be used for 2-5 years | Outdoor wet environment can be used for more than 10 years |

| Applicable temperature | -10°C~80°C | -50°C~300°C |

| Surface treatment | Various colors are available | Mostly metal color, can be brushed. |

| Installation Requirements | Ordinary wood screws can be fixed. | Stainless steel screws are recommended. |

How to choose the hinge material?

Evaluate the usage environment

- Indoor dry environment (such as bedroom closet): Priority zinc alloy hinges

- Kitchen/bathroom/outdoor: stainless steel hinges must be used.

Calculate the weight requirement

Door weight = area (m²) x material density (Example: 0.5m² glass door ≈ 15kg, need stainless steel hinges)

Special needs considerations

- Need mute function → choose stainless steel hinges with damping

- Frequent opening and closing (such as shopping mall doors) → must be 304 stainless steel

purchase to avoid pit guide

- Wary of false material: test with a magnet, real stainless steel is only slightly magnetic

- Check the certification mark: quality products will have SGS, ISO certification

- Test the smoothness of opening and closing: high-quality hinges can be 50,000 times open and close without loose

- Note that the size match: the thickness of the cabinet door needs to be consistent with the hinge specifications

- Recommended brands: Hettich (high-end), haitan (Htan)

FAQ

Will zinc alloy hinges rust completely?

Only surface oxidized spots may appear in a dry environment, but it will gradually rust through in a humid environment.

What is the difference between 304 and 201 stainless steel hinges?

304 contains 8% nickel, better corrosion resistance; 201 contains manganese easy to rust, 30% lower price, not recommended for outdoor use.

How to extend the life of hinge?

Use WD-40 lubricant to maintain every half a year, avoid using acidic cleaner.

Conclusion

Zinc alloy hinges are lightweight, cheap and suitable for indoor dry environment; they are not corrosion-resistant and easy to break at low temperature. Stainless steel hinges are strong load-bearing, rust-resistant and heat-resistant, suitable for wet or outdoor environments, more expensive but more durable. Selection should be based on the use of the environment and load-bearing needs to decide.