HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

-

+86 13720060320

-

lanna@haitangs.com

Ultimate Cold Storage Hinges Selection Guide for Freezers and Walk-Ins

A malfunctioning cold storage door hinge is far more than just an inconvenience. It represents a critical failure point that directly leads to energy waste, spoilage of inventory (food, pharmaceuticals), safety hazards, and costly operational disruptions.

Cold storage hinges are not ordinary door hinges. They are precision-engineered components that must maintain reliable operation under extreme conditions: extreme temperatures, high humidity, and heavy loads. [Cold storage hinges…, Section: Definition and Function of Cold Storage Hinges]

Wrong hinge selection = seal failure = frost buildup = compressor overwork = skyrocketing electricity bills.

This guide provides a comprehensive framework to help you—whether you’re a facility manager, engineer, or purchaser—evaluate, select, and maintain the most suitable cold storage hinges for your application.

We’ll delve into material science, load capacity, critical functions, and mandatory industry standards.

Why do standard hinges fail “catastrophically” in low-temperature environments?

The Physical Impact of Extreme Temperatures

- Material Brittleness: Ordinary carbon steel becomes brittle below freezing, with a sharp decline in impact toughness. This significantly increases the risk of hinges snapping under load.[Cold storage hinges…, Section: Cold Storage Hinges vs Ordinary Hinges: Performance Comparison]

- Lubricant Failure: Standard greases solidify or become extremely viscous at low temperatures, causing hinges to seize, dramatically increasing movement resistance, and ultimately forcing operators to use brute force to open/close doors, damaging the door itself.

Persistent Condensation, Moisture, and Frost

- Corrosion Hotbed: Significant temperature differentials between door interiors and exteriors (e.g., interior -18°C, exterior +25°C) cause continuous condensation on door frames and hardware surfaces.[Cold storage hinges…, Section: Core Features of Cold Storage Hinges]

- Mechanical interference: Frost and ice buildup rapidly encases the moving parts of hinges. This ice obstructs normal hinge movement, applying abnormal stress to hinge arms and bearings, causing deformation or breakage.

Heavy doors and high-frequency use

- Static Load: Cold storage doors are filled with heavy polyurethane foam for insulation, making the door itself extremely weighty.

- Dynamic Stress: In high-traffic areas like commercial kitchens or logistics centers, doors may be opened and closed hundreds of times daily. This frequent dynamic stress severely tests the hinge’s wear resistance.

- Door Sag: Sustained pressure causes hinge bushing wear, leading to door sagging. Once sagging occurs, the door bottom drags on the floor. More critically, gaps form in the door frame seal, causing cold air leakage.[Cold storage hinges…, Section: Core Features of Cold Storage Hinges]

Core Types of Cold Storage Hinges: Function and Application Analysis

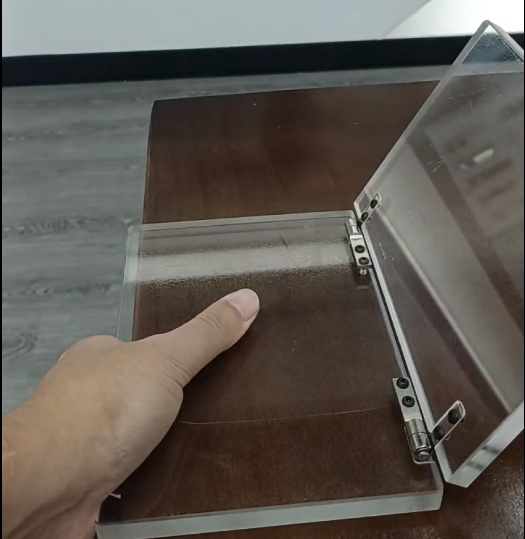

Surface-Mounted Hinges

- Description: The most common type, where the hinge leaf is mounted directly on the surface of the door and frame without requiring mortising.

- Advantages: Simple installation, robust construction, easy replacement, and typically offers the highest load-bearing capacity.

- Disadvantages: Protrudes from the door surface, potentially causing obstruction or collision in narrow passageways.

- Best Suited For: General walk-in cold storage, heavy-duty freezer doors.

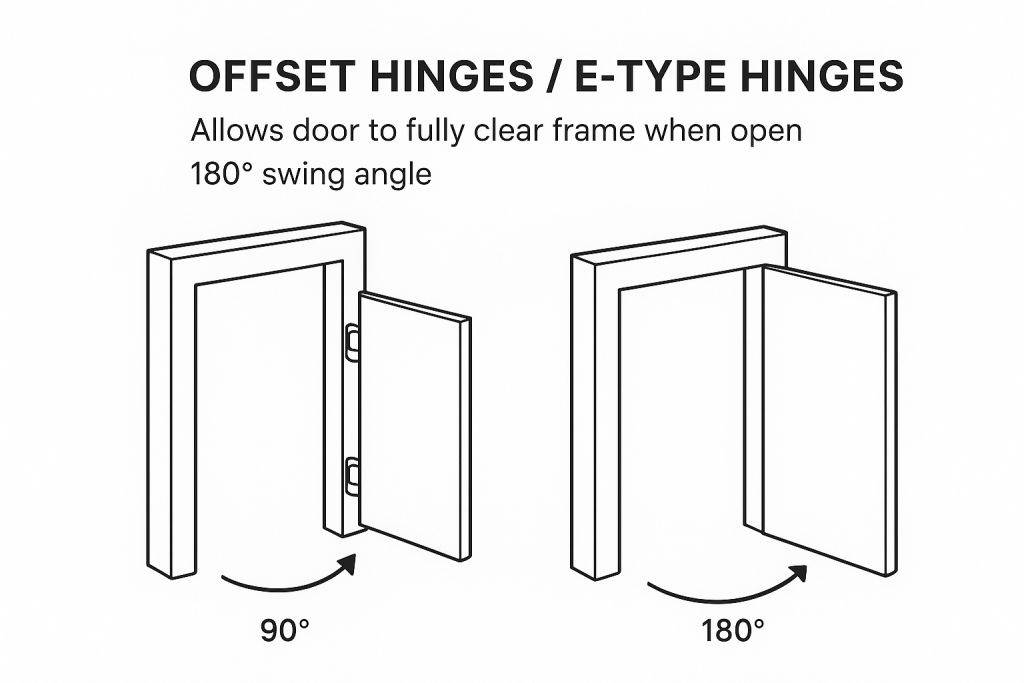

Offset Hinges / E-Type Hinges

- Description: Designed (often with curved arms) to allow the door to swing completely free of the frame when open, clearing the doorway.

- Advantages: Typically provides 180-degree swing angles, maximizing clear doorway width—critical for cart, forklift, and pallet passage.

- Disadvantages: Installation requires precise alignment to ensure correct swing path.

- Best Suited For: High-traffic logistics areas, warehouses, and any application requiring maximized passage width.

Spring-Loaded/Self-Closing Hinges

- Description: Features an integrated spring or cam mechanism that automatically pulls the door back to the closed position after opening.

- Advantages: Key energy saver! Ensures doors close properly after personnel pass through, minimizing cold air leakage and moisture intrusion.

- Disadvantages: Spring mechanism has a mechanical lifespan, potentially requiring periodic tension adjustment or eventual replacement.

- Best Suited For: Virtually all cold storage applications, especially environments prioritizing energy efficiency and temperature stability.

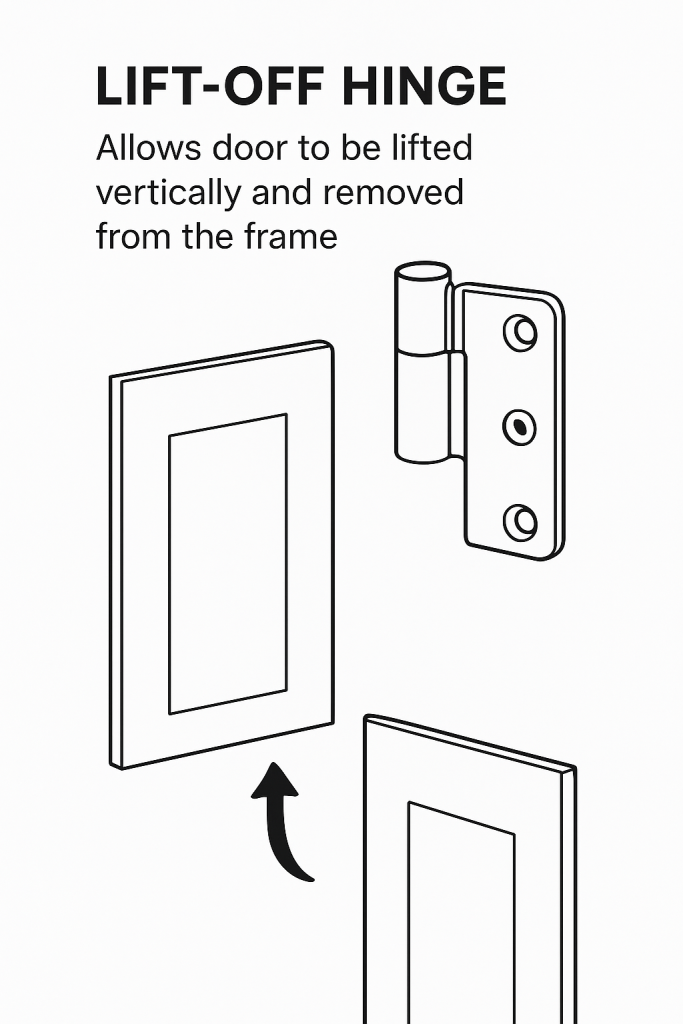

Lift-Off Hinge

- Description: Consists of two independent leaves (one with a pin, one with a socket). Allows the door to be lifted vertically upward and removed from the frame after opening to a certain angle (typically 90 degrees).

- Advantages: Greatly facilitates cleaning, maintenance, and temporary access for large equipment.

- Disadvantages: Load-bearing capacity may be lower than equivalent-sized heavy-duty surface-mounted hinges.

- Best Use: Food processing, pharmaceutical, and medical laboratory environments requiring frequent deep cleaning and washing.

Ultimate Selection Checklist: 10 Key Decision Points for Choosing Cold Storage Hinges

Decision Point 1: Material Composition

Stainless Steel

- 304 Stainless Steel: Industry standard, offering excellent corrosion resistance due to its 18% chromium and 8% nickel content. Its composition complies with ASTM A240 (for sheet) or ASTM A276 (for rod) standards. Suitable for most standard refrigeration and freezer applications.

- 316 Stainless Steel: “Marine-grade” stainless steel. It adds molybdenum (Mo) to the 304 base. This provides superior resistance to chloride corrosion (e.g., salt, disinfectants, cleaning agents).

- When to choose 316: 316 stainless steel is essential in coastal areas (high airborne salt content), seafood processing plants, storage facilities for cured products (e.g., sausages, kimchi), or environments requiring daily rinsing with corrosive cleaning agents.

Galvanized/Chrome-Plated Steel

- Advantages: Lower cost, high base steel strength.

- Disadvantages: Relies on surface coatings (e.g., zinc coating compliant with ASTM B633) for corrosion protection. Once the coating is damaged by impact or wear, the underlying carbon steel rusts rapidly. Never recommended for high-humidity or washdown environments.

Composite Materials/Engineering Plastics

- Advantages: Never rusts, lightweight, self-lubricating (low friction coefficient).

- Disadvantages: Significantly lower load-bearing capacity than metals; must be rigorously evaluated for low-temperature brittleness to ensure compliance with low-temperature impact performance standards such as ASTM D4000. Suitable only for extremely lightweight doors.

Decision Point 2: Load Capacity vs. Door Weight

How to Calculate Door Weight

Do not estimate. Consult the door manufacturer’s Technical Data Sheet (TDS) for accurate weight specifications.

Static Load vs. Dynamic Load

Hinges must withstand both the door’s stationary weight (static load) and the inertial forces generated during opening/closing (dynamic load).

Golden Rule

Select hinges rated well above the door’s actual weight. Industry best practice employs a minimum 1.5x safety factor. Critical Warning: Three hinges do not equal the sum of three independent load capacities. Top hinges primarily bear tensile forces, while bottom hinges primarily bear compressive and shear forces. Manufacturer load guidelines for multi-hinge installations must be strictly followed.

Decision Point 3: Operating Temperature Range

Refrigerator vs. Freezer

- Refrigerator (approx. 2°C (35°F)): The primary challenge is persistent high humidity and condensation, demanding exceptional corrosion resistance from materials.

- Freezer Compartment (approx. -18°C (0°F) to -29°C (-20°F)): Challenges include material low-temperature embrittlement and lubricant failure.

Ensure Specifications Check the hinge’s technical data sheet to confirm its “minimum operating temperature” is below your cold storage unit’s set temperature. Hinges for freezer rooms must use specialized low-temperature grease.

Decision Point 4: Core Functionality: Self-Closing vs. Hold-Open

- Self-Closing: This is essential for energy efficiency. A high-performance self-closing hinge should feature adjustable closing force (tension) to ensure the door overcomes seal resistance for a complete seal without slamming shut.

Hold-Open Automatically holds the door open at a specific angle (e.g., 90 or 120 degrees). This convenience feature facilitates loading/unloading with carts.

Decision Point 5: Adjustability

Why Adjustment is Needed Buildings experience minor settling over time, and door frames may warp, causing door sagging and seal failure.

- Feature to Look For: Seek hinges offering both vertical (up/down) and horizontal (left/right) adjustment. This adjustability allows maintenance personnel to realign the door and compress the seal without removing hinges or re-drilling.

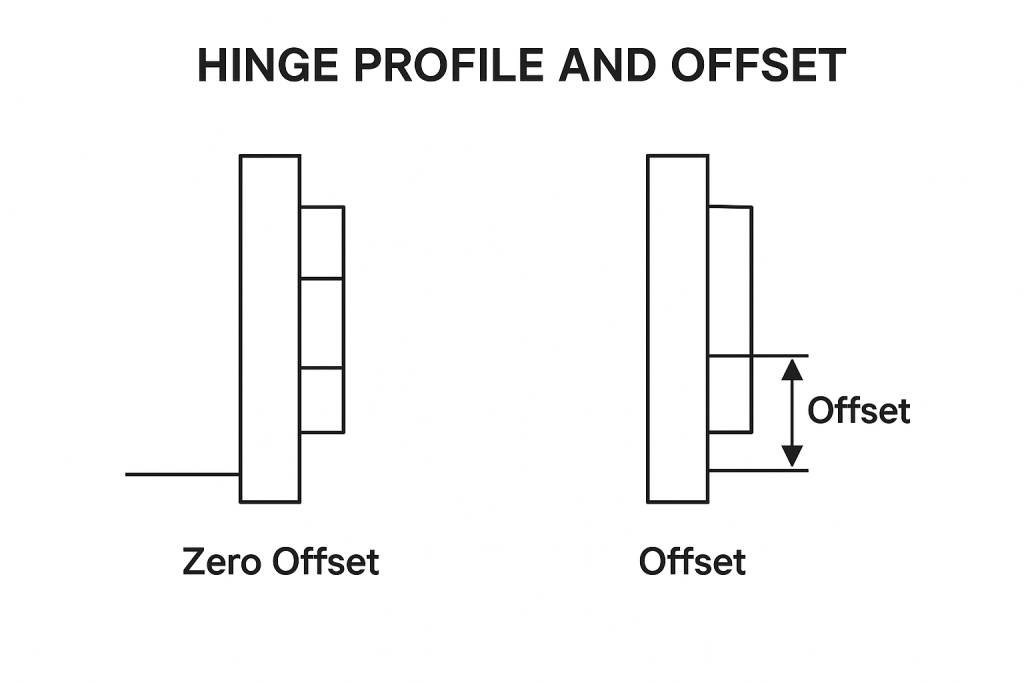

Decision Point 6: Hinge Profile and Offset

Zero Offset (Flush) is used for installations where the door surface aligns flush with the frame surface (flat doors).

Different offsets are used for recessed doors (where the door sits further back than the frame). The offset refers to the horizontal distance between the door surface and the frame surface. Accurate measurement of this offset is critical; incorrect offsets can prevent the door from closing or sealing properly.

Decision Point 7: Safety and Exit

- Internal Release: The hinge function must coordinate with the internal safety release handle (latch system). The hinge must ensure smooth door operation, allowing individuals trapped inside a cold storage facility to push the door open effortlessly.

- Smooth Operation: Hinges must not stick or require excessive force to open at any temperature. This is both an operational efficiency issue and a critical safety concern during emergencies.

Decision Point 8: Maintenance Requirements

Sealed Bearings vs. Greaseable

- Sealed Bearings: The hinge pivot point uses sealed bearings or maintenance-free nylon bushings. This is the preferred option, preventing moisture and cleaning agents from entering and extending service life.

- Greaseable: Features grease zerks. These require periodic maintenance with specialized cryogenic grease.

Decision Point 9: Certification Standards

- NSF Certification: Look for NSF/ANSI 2: Food Equipment certification. This indicates the hinge materials (e.g., stainless steel) are food-safe and designed for easy cleaning without crevices where bacteria can harbor. This is mandatory for food service and processing environments.

- ASTM Standards: Ensure material claims are substantiated. For example, hinge manufacturers should be able to prove their stainless steel meets ASTM A240 or ASTM A276 grade standards.

Decision Point 10: Total Cost of Ownership

Beyond Initial Price

A $50 substandard hinge may cause $500 in annual energy loss due to poor sealing and fail after 2 years, requiring replacement. A $200 premium hinge made of 316 stainless steel with sealed bearings lasts 10 years while maintaining door seal integrity. From a TCO perspective, the latter costs significantly less than the former.

Installation Best Practices: Ensuring Hinge Performance and Longevity

Preparation: Alignment is Key

Before installation, use a level to verify the door frame’s vertical and horizontal alignment.

Ensure the door itself is structurally sound and free from warping.

Fastener Selection

Always use manufacturer-recommended fasteners. For cold storage, this almost always means stainless steel bolts.

When mounting to the door, use through bolts with backing plates to distribute pressure. Absolutely avoid self-tapping screws, as they cannot provide sufficient holding force on heavy doors.

Sealing and Insulation

Ensure proper insulation blocks or thermal breaks are installed behind hinge mounts.

This prevents “thermal bridging”—where cold energy conducts through metal bolts and hinge bases to the exterior, causing external condensation or frost and wasting energy.

Post-Installation Adjustment

Immediately after installation, adjust hinges to ensure the door seal compresses evenly at all points against the frame.

Use the “dollar bill test”: insert a bill between the door and frame, then close the door. You should feel even tension but not be able to easily pull the bill out. Perform this test around the entire door perimeter.

Common Problem Diagnosis & Troubleshooting

Problem: Door sagging or dragging

- Diagnosis: Worn hinge bushings; Loose fasteners; hinges lack sufficient load capacity to support door weight.

- Solution: Immediately tighten all fasteners. If hinges are adjustable, re-level the door height. Replace bushings or entire hinges if wear is evident. If hinges were incorrectly sized initially, upgrade to a higher load capacity model.

Problem: Ice or frost forming on hinges

- Diagnosis: This almost always indicates seal failure rather than a hinge issue. Warm, moist air infiltrates from outside and condenses into frost at the coldest point (metal hinges).

- Solution: Inspect and replace weatherstripping around the door frame. Verify the self-closing mechanism functions properly, ensuring the door seals tightly each time.

Issue: Difficulty opening/closing or sticking

- Diagnosis: Lack of lubrication (if hinges require it); internal corrosion from moisture ingress; misalignment between door and frame causing uneven stress on hinges.

- Solution: Lubricate hinges with specialized cryogenic grease if they have grease nipples. Clean any corrosion or debris from hinge surfaces. Inspect and realign the door.

Conclusion: Your choices determine your operational efficiency

Core Point Recap

Cold storage hinges represent a critical engineering investment, not ordinary hardware to be replaced casually.

Selection must be based on material (preferably stainless steel), load capacity (must include safety margin), functionality (self-closing is essential), and environment (temperature, humidity, chemicals).

Recommendation

Do not cut corners on these critical components. A high-quality, properly installed cold storage hinge will save you thousands of dollars over the next decade in energy, inventory loss, and maintenance costs.

Is your cold storage door leaking air or sticking? It’s time to evaluate your hinges. Browse our cold storage hinge series or contact our technical experts for a free consultation tailored to your specific application.

About Us

With over a decade of industrial hardware design and manufacturing expertise, HTAN specializes in delivering high-performance, reliable cold storage solutions for global food service, healthcare, and logistics industries. Our engineers understand the unique challenges of low-temperature environments and are committed to providing durable products that exceed industry standards.

FAQ

Q1: Why are professional cold storage hinges significantly more expensive than regular door hinges?

The answer lies in both materials and engineering. Cold storage hinges must be made from high-grade austenitic stainless steel (such as SUS 304 or SUS 316) to prevent rusting under continuous condensation and frequent washdowns. They also require precision manufacturing, including specialized cryogenic grease and sealed bearings, to ensure smooth operation at sub-zero temperatures (–25 °C / –13 °F).

You’re paying not just for the metal, but for the precision engineering that ensures long-term energy efficiency, safety, and compliance with food-grade standards.

Q2: Why do my hinges constantly ice up?

Hinge icing is almost always a sign of seal failure—and not a problem with the hinges themselves. When door gaskets age, harden, or when sagging doors create gaps, warm, humid air seeps into the cold chamber. Moisture in the air rapidly condenses and frosts on the coldest surface—the metal hinges.

The solution is to immediately inspect and replace your door gaskets, then re-adjust the hinges to ensure the door fully compresses against the seal.

Q3: My self-closing hinge won’t fully seal the door. Is it broken?

Not necessarily. This usually indicates insufficient tension. Most spring-loaded or cam-lift hinges feature adjustable tension. Over time, or due to temperature fluctuations, you may need to increase spring force. Refer to the manufacturer’s manual and use the proper tools (e.g., a hex wrench) to tighten the spring until it exerts enough force to pull the door closed and compress the seal.

If the door still fails to close even at maximum tension, the spring mechanism may be worn out and require replacement.

Q4: When should I completely replace the hinges?

Look for these three warning signs:

- Visible rust: Any sign of rust (especially on plated steel) means the hinge’s structural integrity is compromised and should be replaced.

- Door sagging: If the door visibly sags or drags on the floor and cannot be corrected through hinge adjustment, the bushings or pivot points may be severely worn.

- Metal dust: Metal powder or debris around the hinge pivot indicates internal bearing failure and metal-to-metal contact.

Q5: Can I replace just one damaged hinge, or must I replace the entire set?

Best practice is to replace the entire hinge set. All hinges on a door share the same load and undergo the same number of open/close cycles, so they wear at a similar rate. If one hinge fails, the others are likely near the end of their service life as well.

Replacing only one hinge creates uneven load distribution—causing the new hinge to bear more stress and wear out faster.

If budget constraints prevent full replacement, make sure the new hinge exactly matches the existing ones in model, size, and offset.

-768x768.png)