HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In the realm of industrial hardware design, we often see one detail consistently overlooked: the handle. Specifically, industrial folding handles are critical components. They must not only save space but also withstand frequent operation and harsh environments.

As a consultant working in hardware selection for many years, I have found that the root cause of many project failures is not the core mechanical structure, but humble components like handles. A broken handle can cause expensive medical equipment to fall or prevent timely maintenance of an outdoor communication cabinet.

This article is not just a list of materials. I will combine actual case studies with technical data to deeply analyze three core folding handle materials: Stainless Steel, Aluminum Alloy, and Reinforced Plastic. We will rely on ASTM and ISO standards to help procurement officers and engineers make the smartest decisions.

Stainless Steel Folding Handles: The Benchmark for Strength and Hygiene

When we discuss “high loads” or “hostile environments,” stainless steel is usually my primary recommendation. However, not all stainless steel is created equal.

Mechanical Strength and Durability Data

In my test data, the tensile strength of stainless steel handles far exceeds that of other materials.

- Material Grades: We primarily focus on AISI 304 and AISI 316 grades.

- Performance Metrics: According to the ASTM A276 standard, the yield strength of 304 stainless steel is typically above 215 MPa, with a tensile strength reaching up to 505 MPa.

- Real-world Application: This means a well-designed stainless steel folding handle can easily withstand a vertical pull force of over 1000N without permanent deformation.

Environmental Adaptability: 304 vs. 316

I often have to correct a common misconception among clients: the belief that “stainless steel never rusts.”

- 304 Stainless Steel: Suitable for most indoor industrial environments. However, in coastal environments with high salt spray, pitting corrosion can still occur.

- 316 Stainless Steel: If you are designing equipment for ships or offshore platforms, I strongly recommend Grade 316. Due to the addition of 2-3% Molybdenum, it offers superior resistance to chloride corrosion.

Hygiene Standards and Surface Treatment

In the food processing and medical industries, guidelines from both the FDA (U.S. Food and Drug Administration) and EHEDG (European Hygienic Engineering & Design Group) emphasize surface “cleanability.”

- Surface Characteristics: Stainless steel surfaces are dense and non-porous, making it difficult for bacteria to breed.

- Treatment Recommendation: I suggest choosing handles that have undergone Electropolishing. This process removes microscopic surface peaks, further reducing the risk of bacterial adhesion and meeting strict pharmaceutical industry standards.

Limitations

We must admit that stainless steel is heavy. For lightweight equipment cases requiring frequent manual handling, solid stainless steel handles may add unnecessary burden. Furthermore, its processing costs (especially precision casting) are generally the highest among the three materials.

Aluminum Alloy Folding Handles: The Balance of Lightweight and Industrial Design

If you are designing aerospace cases, portable measurement instruments, or modern automation equipment, aluminum alloy is usually my recommended best material for folding handles. It achieves a perfect compromise between strength and weight.

Density and Weight Advantages

The density of aluminum alloy is approximately 2.7 g/cm³, which is only one-third of stainless steel (approx. 7.9 g/cm³).

- Case Study: In an avionics equipment case project, by switching the handles from stainless steel to Aluminum 6063, we reduced the weight of each case by 400 grams without sacrificing structural integrity. For air transport, this is a massive advantage.

Surface Treatment: The Critical Role of Anodizing

Untreated aluminum surfaces oxidize easily, turning black and dirtying operators’ gloves. Therefore, I require that all industrial aluminum handles undergo Anodizing.

- Technical Standard: Referencing the MIL-A-8625 Type II standard, the anodic layer not only provides excellent corrosion resistance but also increases surface hardness.

- Aesthetic Value: This process allows us to finish handles in matte black, silver, or natural colors. For modern medical carts or server cabinets that prioritize design aesthetics, aluminum handles offer a premium metallic texture.

Limitations

While aluminum alloy has good strength, its surface hardness is lower than that of stainless steel. In environments with extremely high impact forces (such as heavy mining equipment), aluminum handles may dent or scratch. Additionally, its acid and alkali resistance is weaker than 316 stainless steel, so it is not recommended for chemical scenarios involving direct contact with strong reagents.

Reinforced Plastic Folding Handles: Insulation, Thermal Touch, and Cost-Efficiency

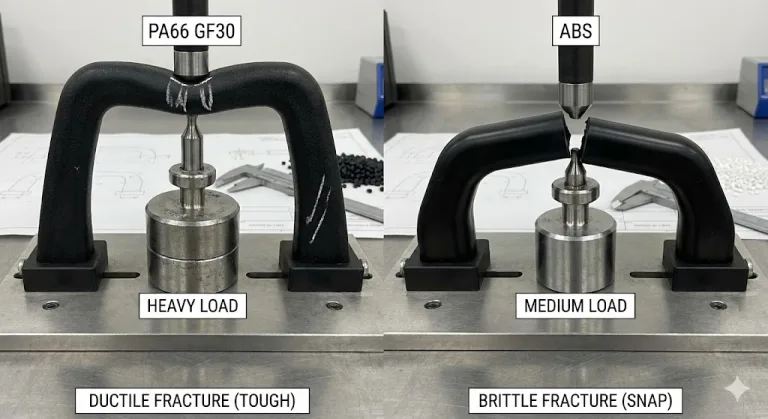

Please do not associate “plastic” with cheap or fragile consumer goods. In the industrial sector, we use Engineering Plastics, most commonly Glass Fiber Reinforced Nylon (PA6 + GF).

Material Composition: More Than Just Plastic

When I specify “plastic” in a technical datasheet, I am referring to a Polyamide 6 (PA6) base material with 30% Glass Fiber (GF) added.

- Performance Boost: According to ASTM D638 testing standards, adding 30% glass fiber can double the material’s tensile strength and significantly enhance its rigidity.

Insulation and Thermal Touch Advantages

This is a unique, irreplaceable advantage of plastic handles.

- Electrical Insulation: For electrical control cabinets or high-voltage equipment, using plastic handles compliant with UL 94 flammability standards (typically HB or V-0 grade) is the safest choice. They are non-conductive, eliminating shock hazards.

- Thermal Touch: If operating equipment in outdoor cold environments (-20°C) or high-temperature environments (60°C), metal handles can feel painful or burn the skin. Reinforced plastic has very low thermal conductivity, making the operation feel much more user-friendly.

Cost and Production Efficiency

For high-volume production (e.g., over 10,000 units), the cost advantage of injection molding is enormous. Through single-shot molding, we can obtain handles with complex structures and precise dimensions at a very low unit price.

Potential Risks

Even with glass fiber reinforcement, the ultimate load-bearing capacity of plastic is lower than that of metal. Furthermore, even with UV stabilizers added, plastic may still experience color fading or embrittlement after long-term exposure (5-10 years) to strong sunlight.

Comprehensive Comparison: Data-Driven Decision Matrix

To help you compare more intuitively, I have compiled the following key parameter table. Please note that these values are based on averages for typical industrial-grade products.

| Comparison Dimension | Stainless Steel (304/316) | Aluminum Alloy (6063/6061) | Reinforced Plastic (PA6+30%GF) |

| Reference Standard | ASTM A276 / AISI | ASTM B221 | ASTM D638 / UL 94 |

| Tensile Strength | High | Medium | Medium-Low |

| Weight | Heavy | Light | Lightest |

| Corrosion Resistance | Excellent (316) | Good (After Anodizing) | Excellent (Chemical Resistance) |

| Working Temp | -50°C to +300°C | -40°C to +150°C | -30°C to +100°C |

| Electrical Insulation | No (Conductive) | No (Conductive) | Yes (Insulated) |

| Cost Index | $$$ (High) | $$ (Medium) | $ (Low) |

Selection Guide: How to Decide Based on Application Scenarios?

As a consultant, I do not believe in “one-size-fits-all” solutions. Here is the decision logic I summarize based on different client needs:

Food & Beverage or Marine Engineering

- Key Needs: Corrosion resistance, easy cleaning, compliance with hygiene regulations.

- My Recommendation: You must choose 316 Stainless Steel Folding Handles.

- Reasoning: Any coating peeling or rust is zero-tolerance in these industries. Only electropolished 316 stainless steel can meet FDA and HACCP requirements.

Outdoor Mobile Equipment or Portable Instruments

- Key Needs: Lightweight, weather resistance, modern appearance.

- My Recommendation: Choose Black Anodized Aluminum Alloy Handles.

- Reasoning: It achieves a balance between durability and weight. If the equipment is exposed to severe cold for long periods, consider a hybrid design with an aluminum handle and a plastic grip.

Electrical Cabinets or High-Frequency Machinery

- Key Needs: Insulation safety, comfortable operation, cost control.

- My Recommendation: Choose Glass Fiber Reinforced Nylon Handles.

- Reasoning: Apart from meeting UL safety standards, plastic handles offer better tactile feedback during frequent operation and do not generate noise like metal handles.

Conclusion

When selecting industrial folding handles, there is no absolute “best material,” only the most “suitable” material.

- If your priority is ultimate strength and hygiene, pay the premium for Stainless Steel.

- If you pursue lightweight and visual texture, Aluminum Alloy is the perfect engineering choice.

- If you focus on insulation safety, ergonomics, and high-volume cost, Reinforced Plastic is not just sufficient, but excellent.

I recommend requesting samples for actual installation testing before finalizing the design. Always ask suppliers for a Material Certificate based on the ASTM or ISO standards mentioned in this article. This is the first step in ensuring product quality.

FAQ

Q1: Will aluminum alloy handles rust when used outdoors?

Strictly speaking, aluminum does not “rust” like iron. It oxidizes. If the aluminum handle has undergone anodizing treatment compliant with MIL-A-8625, it forms a hard protective film that is very suitable for outdoor use. However, if located in a seaside area with high salt spray, this protective film may degrade over time. In that case, I still recommend using 316 Stainless Steel.

Q2: Can reinforced plastic handles really withstand industrial loads?

Yes, provided you choose correctly. Typical industrial-grade PA6+30%GF folding handles feature reinforced designs around mounting holes. Their vertical lifting force can usually reach 500N to 1000N. For most carrying cases, server chassis, or equipment access doors, this strength offers a significant safety margin.

Q3: How can I tell if a stainless steel handle is 304 or 316?

It is difficult to distinguish with the naked eye. The most reliable method is to request a material spectrum analysis report from the supplier. For a quick on-site test, you can use a specialized stainless steel test fluid (Molybdenum test fluid). If the droplet turns black on the metal surface, it usually indicates the presence of Molybdenum, confirming it is 316 Stainless Steel.

Q4: What material is the return spring typically made of?

This is an excellent detail question. Regardless of whether the handle body is aluminum or plastic, I always recommend checking if the internal spring and pin are made of 304 Stainless Steel. Many low-end products use carbon steel springs, which are the first components to corrode and fail.

Q5: Will reinforced plastic handles become brittle at low temperatures?

Ordinary plastic does become brittle. However, high-quality Engineering Nylon (Polyamide) possesses good toughness. In my experience, reinforced nylon handles retain sufficient impact resistance in -30°C environments. If used in more extreme polar environments, you need to request a custom cold-resistant modified formula from the supplier.

-768x768.png)