HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In industrial hardware engineering, hinge pins are the critical rotational axes that must simultaneously withstand mechanical shear, abrasive wear, and environmental oxidation. Failure to select the correct material often leads to “hidden corrosion” within the hinge barrel, resulting in seized mechanisms, structural door sag, or catastrophic component failure in the field.

Technical Definitions and Scope

AISI 304 Stainless Steel

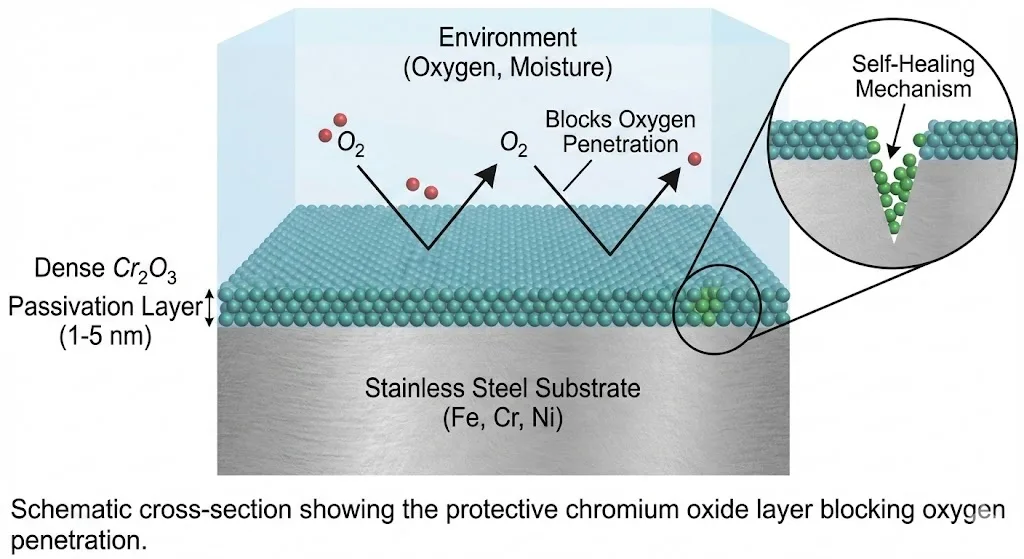

AISI 304 is an austenitic stainless steel defined by ASTM A240. It contains a minimum of 18% Chromium and 8% Nickel. This composition facilitates the formation of a self-healing chromium oxide layer, which is why 304 is widely specified for corrosion-prone industrial hinge applications.

Industrial Hinge Pin

The hinge pin is the central pivot point of a hinge assembly. It acts as the primary load-bearing element during rotational movement. Because the pin carries shear load and sliding wear at the same time, material selection directly affects service life, maintenance cost, and field reliability.

Passivation

Passivation is a chemical treatment per ASTM A967. It removes free iron from the pin surface and enhances the thickness and stability of the protective oxide layer. In humid or outdoor installations, passivation is one of the most effective ways to reduce “hidden corrosion” inside the hinge barrel.

Material Performance Matrix

The following data compares common materials used in industrial pivot applications.

| Metric | Galvanized Carbon Steel | 201 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel |

| Yield Strength (MPa) | 250 – 350 | 290 – 310 | 205 – 215 | 205 – 210 |

| Relative Corrosion Resistance (Typical Industrial Use) | Low (high risk of rust) | Moderate (may rust in humid/outdoor use) | High (excellent in most industrial environments) | Very High (best for chloride / coastal exposure) |

| ASTM Standard | A36 | A666 | A276 / A479 | A276 |

| Relative Cost Index | 1.0 | 1.5 | 2.2 | 3.5 |

| Lifecycle (Cycles) | <20,000 | 50,000 | >100,000 | >100,000 |

Precision Calculation Model for Hinge Pins

Shear Stress Formula

Engineers must verify the pin diameter against the maximum door load.

Formula: Tau = F / A

Where:

- Tau = Shear Stress (MPa)

- F = Force applied to the pin (N)

- A = Cross-sectional area of the pin (mm^2)

Note: Because 1 N/mm^2 equals 1 MPa, the calculated value from F (N) and A (mm^2) directly converts to MPa.

Worked Example

Calculate the shear stress for a 150 kg industrial enclosure door using two hinges. The pin diameter is 10 mm.

- Calculate Force (F) per pin: F = (150 kg * 9.81 m/s^2) / 2 = 735.75 N

- Calculate Area (A): A = 3.14159 * (5 mm)^2 = 78.54 mm^2

- Calculate Stress (Tau): Tau = 735.75 / 78.54 = 9.37 MPa

Result: The calculated 9.37 MPa is significantly below the 304 yield strength (205 MPa). This design offers a safety factor of approximately 21.

Technical Field Notes: The “Hidden Corrosion” Failure

Scenario: A manufacturer used 201 stainless steel pins for outdoor electrical cabinets in a humid region.

Observation: Within 14 months, the hinges seized. Testing revealed “hidden” oxidation inside the hinge barrel where moisture trapped manganese salts.

Solution: Replaced all units with 304 stainless steel pins treated with ASTM A967 citric acid passivation. Seizing incidents dropped to zero over the next 36 months.

Comparative Analysis: Best Practice vs. Substandard

| Feature | Industry Best Practice | Substandard Practice | Impact of Substandard |

| Tolerance Fit | H7/f7 Precision Grind | Loose clearance (>0.5mm) | Excessive door sag and vibration |

| Material Verification | EN 10204 3.1 Certificate | No certification | Unpredictable corrosion resistance |

| Surface Finish | Ra 0.8 – 1.6 μm | Rough turned (>3.2 μm) | Accelerated friction and wear |

| End Retention | Circumferential riveting | Friction fit | Pin migration and assembly failure |

Failure Mode and Effects Analysis

| Failure Mode | Potential Cause | Impact on System | Prevention Strategy |

| Galling | Lack of lubrication + High load | Total hinge seizure | Use 304 pins with PTFE bushings |

| Pitting | Chloride exposure | Pin fracture | Upgrade to 316 or frequent cleaning |

| Work Hardening | Excessive cold forming | Stress corrosion cracking | Proper annealing per ASTM A240 |

| Pin Migration | Inadequate retention | Door detachment | Use circlips or headed pins |

Reliability and Validation Standards

Hinge pins must undergo the following verification steps:

- Corrosion Resistance: Perform ASTM B117 neutral salt spray testing. 304 pins must show no red rust for 168 hours.

- Mechanical Integrity: Conduct cycle testing per ISO 19353. Pins must maintain structural integrity over 100,000 cycles.

- Chemical Purity: Verify Chromium and Nickel levels via PMI (Positive Material Identification) to ensure compliance with AISI specifications.

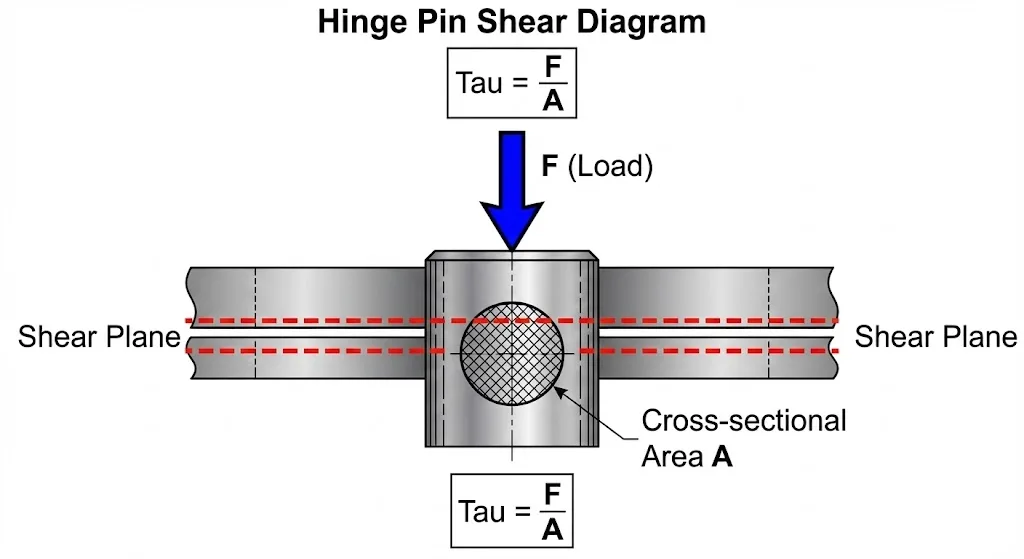

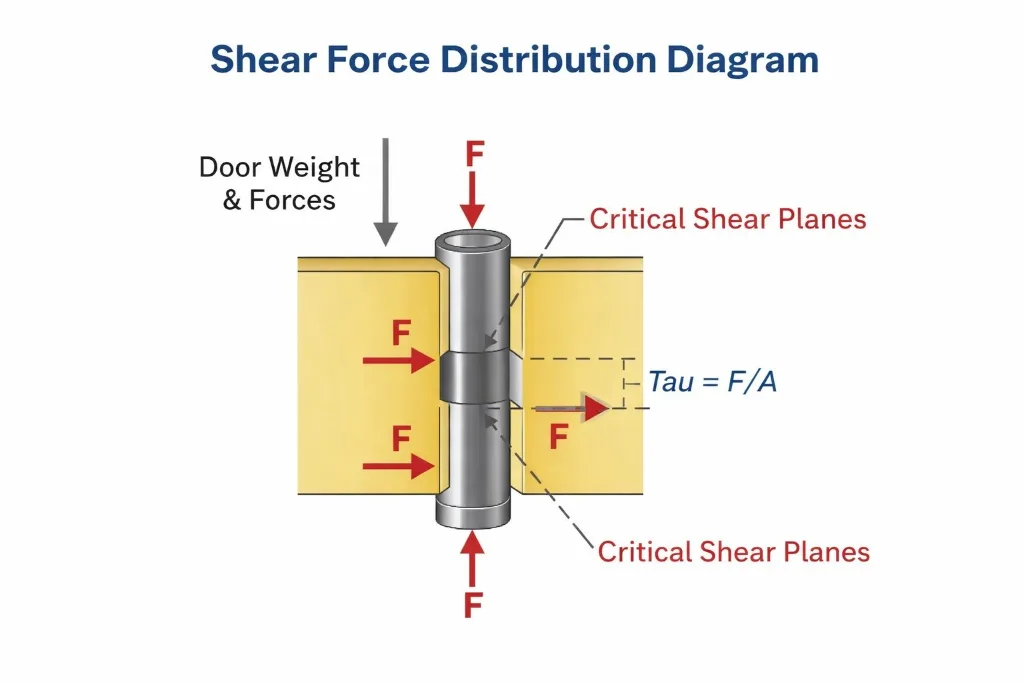

Engineering Illustrations

The following engineering illustrations provide a clear visual explanation of how load is transferred through a hinge pin and why corrosion protection methods such as passivation directly improve long-term reliability. These visuals are commonly used in technical reviews, training, and procurement validation.

Shear Force Distribution Diagram

A shear force distribution diagram helps visualize how door weight and operational forces translate into shear loading on the hinge pin. It highlights the primary load path through the hinge leaves and identifies the critical shear planes where stress is highest. This concept supports proper pin diameter selection and reinforces why shear calculations (Tau = F/A) are essential for safe design.

Passivation Layer Detail

A passivation layer diagram illustrates the ultra-thin chromium oxide film (approximately 1–5 nm) that forms on 304 stainless steel. This passive layer acts as a barrier over the substrate, slowing oxidation and reducing the risk of “hidden corrosion” inside the hinge barrel. It is especially useful for explaining why ASTM A967 passivation improves long-term performance in humid, outdoor, or corrosive environments.

Quick Selection Summary (Recommended)

- Standard industrial indoor use: 304 stainless steel hinge pins + basic lubrication.

- Humid or outdoor cabinets: 304 stainless steel + ASTM A967 passivation + periodic maintenance.

- Coastal / chloride exposure: Upgrade to 316 stainless steel to reduce pitting risk.

- High-cycle applications: 304 + tight tolerance fit + PTFE bushings to reduce wear and galling.

Procurement Checklist (Checklist)

- Verify AISI 304 chemistry via EN 10204 3.1 MTC.

- Confirm pin diameter tolerance meets ISO 286-2 (e.g., f7 or g6).

- Ensure surface roughness (Ra) is documented below 1.6 μm.

- Validate that the pin is non-magnetic or weakly magnetic (low ferrite content).

- Check for ASTM A967 passivation records.

- Inspect pin ends for uniform chamfering (typical 0.5mm x 45°).

- Review salt spray test reports for 168-hour compliance.

- Confirm the load rating exceeds the calculated peak shear stress by a factor of 5.

FAQ

Q1: Can 304 stainless steel pins be used in salt-water environments?

A1: No. 304 stainless steel is susceptible to chloride pitting. For marine or coastal environments, specify 316 stainless steel per ASTM A276.

Q2: Why is my 304 hinge pin magnetic?

A2: Cold working transforms austenite into martensite, which is magnetic. It does not indicate a material defect, though it may slightly reduce corrosion resistance in extreme cases.

Q3: How often should 304 hinge pins be lubricated?

A3: In standard industrial environments, lubricate every 12 months. High-cycle applications (over 100 cycles per day) require a 3-month maintenance interval.

Q4: Does 304 stainless steel react with aluminum hinge leaves?

A4: Yes. Dissimilar metal contact can cause galvanic corrosion. Use an insulating bushing or ensure the pin is passivated to mitigate this risk.

Q5: What is the maximum operating temperature for a 304 pin?

A5: 304 stainless steel has good oxidation resistance at elevated temperatures, but mechanical strength decreases as temperature rises. In practical hinge applications, lubrication and surrounding components usually set the real operating limit long before the material reaches its high-temperature capability.

Q6: Is 304L better than 304 for hinge pins?

A6: 304L (Low Carbon) is superior for components requiring heavy welding. For standard machined pins, 304 provides slightly higher strength and is the more common choice.