HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In the realm of industrial hardware design, I consistently see one detail overlooked: Folding Handles.

These components are critical for server chassis, precision medical devices, portable measurement instruments, and military transit cases. Their core value is clear: saving space when idle and preventing accidental impacts in narrow aisles.

However, based on my observation, many project failures do not stem from core mechanical structural defects, but from these seemingly insignificant accessories. Many procurement officers and junior engineers focus solely on the “dimensions” or “unit price” listed in a catalog. They ignore the dynamic stress environment of the equipment and the actual operational logic of the user.

The consequences of this oversight are expensive. I have seen medical terminals worth thousands of dollars smash onto the floor because a handle snapped during transport. I have seen outdoor telecom cabinets become inaccessible for emergency maintenance because the handles rusted shut.

This article is not a basic definition textbook. As a consultant focused on mechanical structure selection, I will analyze the 5 critical selection mistakes that lead to product failure from an engineering failure analysis perspective. I will provide data-driven solutions and specific international standard references to help you mitigate risk early in the design phase.

Mistake 1: Confusing Static Load with Dynamic Safety Factors

This is the most frequent error I find when reviewing client BOMs (Bill of Materials).

The Error Description

Most supplier specification sheets only list “Max Static Load” or “Rated Load.”

For example, a handle is rated for 500N (approx. 50kg). Procurement personnel often match this directly: the equipment weighs 45kg, so they select the 50kg rated handle.

Mathematically, this looks reasonable. In the physical world, however, this is dangerous.

Technical Consequences: Impact and Fatigue

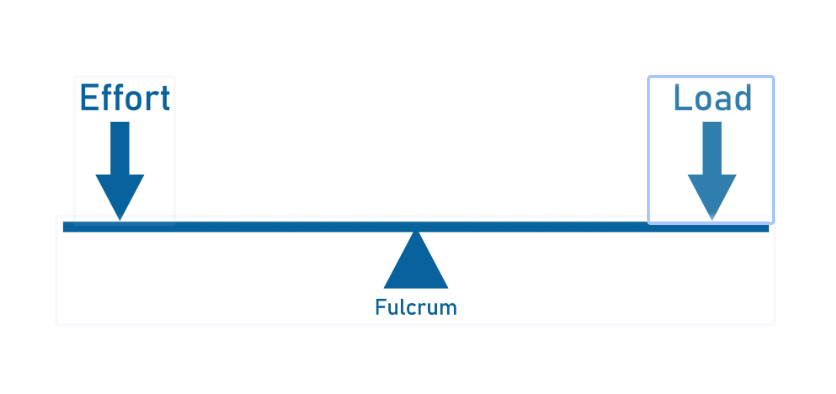

Dynamic Impact Fracture: Acceleration occurs during walking, climbing stairs, or loading/unloading. According to Newton’s Second Law ($F=ma$), when equipment is subjected to impact, the instantaneous force (G-force) on the handle can reach 2 to 3 times the equipment’s self-weight.

- Case Study: A 50kg chassis dropped accidentally from a height of 5cm can exert a momentary pull force exceeding 1500N on the handle. If the handle is rated for only 500N, the pivot pin will shear immediately.

Fatigue Failure: If a handle operates near its rated load limit for long periods, metal parts will develop fatigue cracks, or plastic parts will experience creep, leading to eventual failure.

Figure 1: Visualizing the difference between static holding force and dynamic impact force.

Consultant’s Advice and Avoidance Strategy

Implement a Strict Safety Factor

I strongly recommend using a Safety Factor of 1.5x to 2.0x for industrial-grade equipment.

- Calculation Formula:$$Recommended Rated Load = (Total Equipment Weight / Number of Handles) \times Safety Factor$$

- Example: For 50kg equipment with 2 handles and a Safety Factor of 2.0, you should purchase handles rated for at least 50kg (500N) each, not 25kg.

The Myth of Load Sharing

Do not assume two handles always share the weight equally. During actual transport, especially on stairs or tight corners, equipment often tilts. Our testing shows that at a 30-degree tilt, a single handle may need to bear over 70% of the equipment’s weight. Therefore, selection must be based on the “Single Handle Limit.”

Cite Test Standards

When communicating with suppliers, demand test reports based on IEC 60068-2-27 (Shock Test) standards, not just static tensile reports.

Mistake 2: Ignoring Grip Clearance for Gloved Operation

To pursue a compact equipment profile, designers often tend to select folding handles with small cross-sections and tight fits. This leads to severe ergonomic failures.

The Error Description

The selected handle has insufficient clearance between the inner grip and the panel (Grip Clearance), or the grip width is too narrow.

Technical Consequences: Operational Blockage and Safety Risks

Inoperability in Cold Environments: In outdoor base stations or cold chain logistics, operators must wear thick thermal gloves. If the handle clearance is only 25mm, a gloved finger simply cannot fit.

Pinch Points: Some poorly designed folding handles crush the operator’s knuckles against the pivot geometry when lifted.

Case Study: I participated in retrofitting a portable field server project. The original design used compact handles, but during testing at -20°C, soldiers wearing winter gear could not deploy the handles quickly, causing deployment delays.

Figure 2: Ergonomic clearance requirements for gloved operation.

Consultant’s Advice and Avoidance Strategy

Follow Ergonomic Data

When selecting, you must reference data from MIL-STD-1472 (Human Engineering Design Criteria for Military Systems).

- Bare Hand Operation: Minimum grip width should be 100mm, with a minimum depth clearance of 30mm.

- Gloved Operation: Minimum grip width must increase to over 120mm, and depth clearance is recommended at 40mm – 50mm.

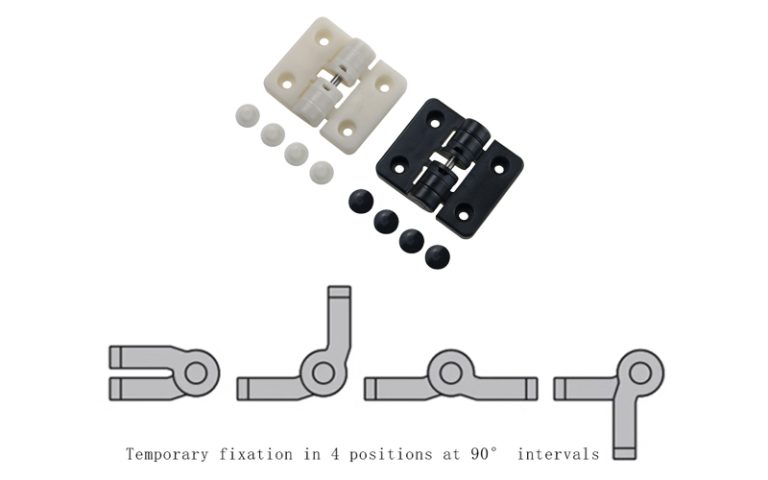

90-Degree Stop Design

I recommend choosing folding handles with a 90-degree Stop feature.

This handle stops automatically when unfolded to 90 degrees perpendicular to the panel. This ensures maximum force transmission efficiency and guarantees the maximum distance between the handle and the panel, preventing knuckles from scraping against rough chassis surfaces under load.

Mistake 3: Overlooking Noise and Wear in High-Vibration Environments

If your equipment is installed on vehicles, ships, or generator sets, this issue is critical.

The Error Description

Selecting “Free-swinging” folding handles without locking or damping functions. These handles rely on gravity to hang down when not in use.

Technical Consequences: Noise Pollution and Surface Damage

High-Frequency Noise: When equipment is running (e.g., a vehicle cabinet driving on a bumpy road), free-swinging handles constantly impact the panel. This continuous “rattling” creates noise pollution and gives users the impression of “loose equipment” or “low quality.”

Coating Failure and Corrosion: Our salt spray tests show that hundreds of micro-impacts per minute rapidly destroy protective coatings (like anodizing or powder coating) on both the handle and the panel. Once the coating breaks, the substrate is exposed, and rust spreads quickly.

Consultant’s Advice and Avoidance Strategy

Mandate a Return Mechanism

For any mobile equipment, I require the use of one of these three handle types:

- Spring-loaded: The handle contains an internal torsion spring. Upon release, the handle automatically folds tight against the panel and maintains continuous pre-tension, completely eliminating wobble.

- Detent/Click: Mechanical detents are placed at the folded and unfolded positions. The user feels a distinct “click,” and the handle will not shift due to minor vibrations.

- Friction/Damping Hinge: Using high-viscosity damping grease, the handle can hover at any angle. This offers a premium, silent, and smooth movement feel.

Rubber Buffer Design

Check if the handle design includes a Rubber Bumper. Even with spring-loaded handles, metal impacting metal causes noise and wear. A buffer is a low-cost key to solving wear issues.

Cite Test Standards

Require the supplier to confirm the product has passed MIL-STD-810G Method 514.6 (Vibration Test) .

Mistake 4: Material Mismatch with Environmental Stress

Many failures occur not because the material isn’t strong enough, but because the right material was put in the wrong place.

The Error Description

Selecting materials based on indoor laboratory conditions, but applying the product in outdoor, marine, or chemical scenarios.

Technical Consequences: Galvanic Corrosion and Aging

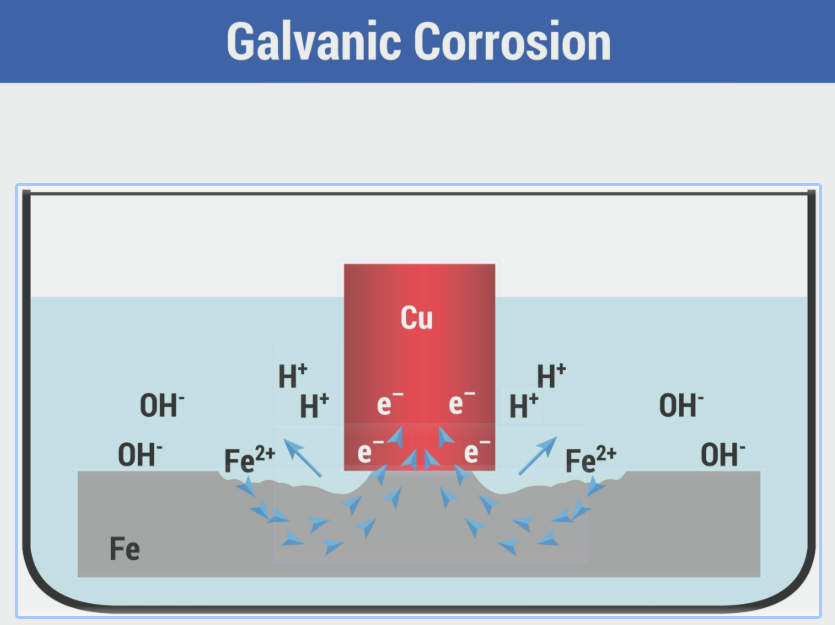

Galvanic Corrosion: This is a classic advanced engineering error. If an Aluminum Alloy handle is installed directly onto a Stainless Steel chassis, a battery effect is created due to the difference in electrode potential. In humid or salty environments, the aluminum becomes the anode and corrodes at an accelerated rate, eventually leading to catastrophic fracture at the handle base.

UV Degradation: Standard Nylon (PA6) handles will yellow and become brittle within 6 months under strong outdoor UV exposure. Impact strength can drop by more than 50%.

Figure 2: How mixing Aluminum and Stainless Steel creates a corrosion cell.

Consultant’s Advice and Avoidance Strategy

Marine and Medical Environments: Specify SUS316

If the equipment is used on ships, seaside facilities, or medical environments requiring frequent sterilization, do not try to save money with 304 Stainless Steel.

You must specify AISI 316 (or EN 1.4404) Stainless Steel. 316 contains Molybdenum, giving it superior resistance to chloride (salt) corrosion compared to 304.

- Reference Standard: Require passing ASTM B117 Salt Spray Test for at least 500 hours with no red rust.

Treatment for Outdoor Aluminum Handles

If you must use aluminum handles outdoors (for weight reduction), demand Hard Anodizing or outdoor-grade powder coating. Crucially, you must use insulating washers (plastic or rubber) during installation to physically isolate the handle from dissimilar metal panels, breaking the galvanic corrosion path.

Selection of Engineering Plastics

For outdoor plastic folding handles, the specification sheet must state the use of “UV Stabilized” materials, typically Glass Fiber Reinforced Nylon.

- Reference Standard: UL 746C (Polymeric Materials – Use in Electrical Equipment Evaluations)

Mistake 5: Incorrect Mounting Causing Panel Deformation

This is a detail structural engineers often miss: The handle is strong, but is your chassis panel strong enough?

The Error Description

Installing high-load folding handles directly onto thin sheet metal (e.g., 1.0mm or even 0.8mm thickness) without back reinforcement.

Technical Consequences: Stress Concentration and Failure

Permanent Deformation: When lifting heavy loads, force is not distributed evenly but concentrated around the two mounting holes. Thin sheet metal will bend, causing paint to crack or even pulling the screw holes through the metal.

Thread Stripping: Many folding handles use Front Mounting. If tapping threads into thin sheet metal, there are insufficient threads (usually fewer than 3 turns). Heavy lifting will easily strip the threads.

Consultant’s Advice and Avoidance Strategy

Back Reinforcement Strategy

For panels thinner than 1.5mm, I recommend adding a Stiffener or a large surface area Backing Plate behind the handle installation point. This expands the load-bearing area multiple times, effectively dispersing stress.

Prioritize Rear Mounting

Where possible, choose Rear Mounting folding handles.

- Security: Screws pass from the inside of the chassis to fix the handle; no screw heads are visible from the outside. This is aesthetically pleasing and tamper-proof.

- Load Bearing: This structure is usually used with large washers, offering far superior pull-out resistance compared to front mounting which relies on just a few threads.

The Actionable Checklist for Procurement Managers

Before sending your RFQ (Request for Quotation) to suppliers, verify against this checklist:

- Load Definition: Do not just provide weight. Specify: “Total equipment weight 50kg, require single handle dynamic safety factor 2.0 (i.e., single handle bears 100kg), and provide shock test data.”

- Dimensional Check: Confirm handle inner width is >120mm (if gloved operation is needed). Request CAD drawings for 3D interference checking.

- Functional Verification: Clarify the return mechanism. Specify: “Must have internal spring or damping structure; free-swinging is prohibited.”

- Environmental Match:

- Outdoor/Marine: Specify SUS316 or UV-Stabilized Nylon.

- Reference Standards: ASTM B117 (Salt Spray) or UL 746C (UV).

- Mounting Interface: Confirm panel thickness. If the panel is too thin, request the supplier to provide matching backing plates or large washers.

Conclusion

Selecting an industrial folding handle is not just about “can it lift the equipment.”

It is about operator safety in extreme environments, durability over the equipment’s lifecycle, and the intuitive perception of quality by your end-user.

As a consultant, my final recommendation is: Do not wait until the molds are cut to select accessories. During the early design phase (EVT), request samples from suppliers to perform actual drop tests and vibration tests. Testing costs spent early will help you avoid aftermarket recall risks that can cost 10 times more.

FAQ

Q: What is the recommended safety factor for industrial folding handles?

A: We recommend a safety factor of at least 1.5x. For lifting critical medical equipment, military gear, or products in high-risk transport environments, we recommend a safety factor of 3.0x to account for dynamic impact forces.

Q: How do I prevent folding handles from making rattling noises?

A: The most effective method is to select handles with an Internal Spring Return Mechanism or Damping Hinge Structure. This ensures the handle stays tight against the panel when idle. Additionally, check if the handle design includes rubber bumpers, which are key to eliminating metal-on-metal impact noise.

Q: What is the difference between 304 and 316 Stainless Steel handles?

A: The primary difference is corrosion resistance. 316 Stainless Steel contains 2-3% Molybdenum, giving it far superior resistance to chloride (salt) corrosion compared to 304. For marine environments, ship decks, and medical settings requiring aggressive sterilization, 316 is the mandatory choice.

Q: Are plastic folding handles strong enough for industrial loads?

A: Yes, provided the right material is selected. Industrial-grade Glass Fiber Reinforced Nylon (PA6 + 30% GF) has very high tensile strength. Quality engineering plastic folding handles can typically withstand pull forces of 500N to 1000N, while offering excellent insulation and thermal touch properties.