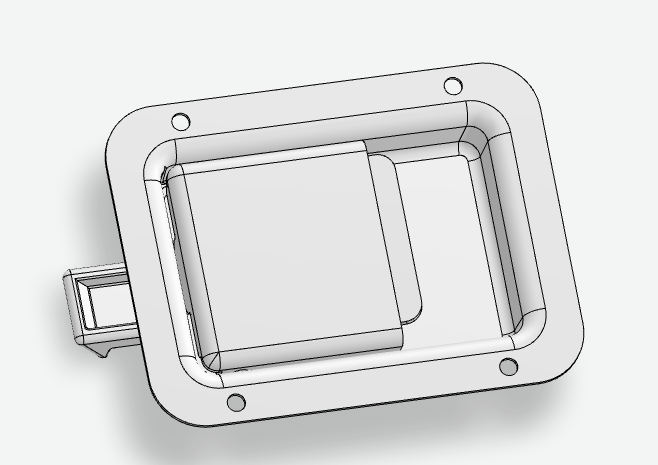

HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Industrial handles endure frequent operation under extreme conditions, and material selection directly impacts equipment safety, ergonomics, and service life. Engineers must choose materials that offer both high strength and corrosion resistance (NACE International, Corrosion Basics: An Introduction, 3rd ed., 2012)Research indicates industrial door handles should utilize high-strength, corrosion-resistant materials (such as stainless steel or aluminum alloys) to withstand heavy use without rusting (ASTM A240, ASM International, Stainless Steels: Properties and Applications, 2017).

Thus, in high-load scenarios like manufacturing, transportation, or automation, material performance is critical to equipment reliability. This article comprehensively compares stainless steel and aluminum alloy handles based on mechanical properties, corrosion resistance, weight, and cost to assist equipment buyers and engineering decision-makers in making informed choices. Before delving into the comparison, let’s first understand the fundamental characteristics of both materials. For a broader overview of handle materials and their classifications, see our types and material overview of industrial handles

Comparison Between Stainless Steel Handles and Aluminum Handles

Overview of Stainless Steel and Aluminum as Handle Materials

Stainless steel

Stainless steel is a chromium-based alloy containing at least 10.5% Cr, known for its outstanding oxidation and corrosion resistance. Common industrial grades include 304, 316, and 201.

- Grade 304 (≈18–20% Cr, 8–10% Ni) offers excellent rust resistance and is widely used in food processing equipment and medical devices where hygiene is critical.

- Grade 316, with 2–3% molybdenum (Mo), provides superior resistance to chloride-induced corrosion, making it ideal for marine and chemical environments.

- Grade 201 contains less nickel, offering a more economical alternative but with reduced corrosion resistance.

Comparison of 304, 316, and 201 Stainless Steel Handles

Stainless steel handles are characterized by high mechanical strength, smooth, easy-to-clean surfaces, and long service life. The typical density of industrial-grade stainless steel is around 8.0 g/cm³.

Aluminum alloys

Aluminum alloys, on the other hand, are valued for their lightweight and excellent machinability. With a typical density of 2.70 g/cm³—roughly one-third that of stainless steel—they significantly reduce component weight. Common alloys include 6061, 6063, and 7075:

- 6061-T6 offers a high strength-to-weight ratio and good fatigue resistance, though slightly less corrosion resistance than 6063.

- 6063 excels in surface finish quality and corrosion resistance, making it suitable for decorative or exposed components.

Aluminum alloys are cost-effective, easily extruded or formed, and adaptable to a wide range of designs. However, Without proper surface treatments such as anodizing or powder coating, aluminum alloys can lose up to three times more mass in salt-spray environments compared to anodized counterparts (MDPI, 2023).Anodizing significantly improves corrosion resistance and surface hardness.

While both stainless steel and aluminum alloys are suitable for industrial handle applications, their distinct mechanical, chemical, and economic properties significantly influence long-term performance and total cost of ownership.

Performance Comparison: Stainless Steel vs. Aluminum Alloy

Mechanical Strength and Load-Bearing Capacity

Stainless steel possesses significantly higher tensile strength than aluminum alloys. For comparison, cold-worked 304 stainless steel typically achieves tensile strengths of 540–750 MPa, while heat-treated 6061-T6 aluminum alloy (solution-aged condition) reaches around 310 MPa.

Although their strengthening mechanisms differ, these grades represent typical materials used in industrial handles.

In contrast, while aluminum alloys offer lower strength, they significantly reduce weight while preserving structural integrity. Therefore, stainless steel handles are preferred for heavy-duty machinery, transport vehicles, and other high-stress applications. For equipment or portable systems prioritizing lightweight design, aluminum alloys may be considered.

Corrosion Resistance and Environmental Adaptability

Stainless steel possesses a natural passivated oxide layer that resists corrosion from high humidity, acids, alkalis, and most cleaning agents. Grade 316 stainless steel is particularly corrosion-resistant, often referred to as “marine-grade” material suitable for outdoor, food-grade, and marine environments, offering greater long-term reliability.

While aluminum alloys also form a thin oxide layer for protection, they are more vulnerable to electrochemical corrosion when exposed to salt spray, strong acids or alkalis, or when in contact with dissimilar metals. Overall, stainless steel provides significantly superior corrosion resistance compared to standard aluminum alloys in harsh environments such as marine settings, chemical plants, and food processing facilities. Aluminum alloys, however, perform well in general indoor or non-corrosive applications.

Durability, Wear, and Maintenance

Stainless steel handles maintain structural stability under dynamic loads such as vibration and impact, resist deformation, and virtually never rust (ASM International – Stainless Steels). Their smooth surfaces typically require only periodic cleaning or polishing to restore luster.

Aluminum alloy handles, however, are more prone to plastic deformation under high stress or repeated torque. Since they contain no iron, their surfaces do not rust, but they are often anodized to enhance corrosion resistance (MDPI – A Review on Anodizing of Aerospace Aluminum Alloys for Corrosion Protection). This process requires additional treatment and ongoing maintenance to preserve the oxide layer’s integrity. Overall, stainless steel handles offer easier maintenance and longer service life, while aluminum alloy handles demand more surface care yet remain resistant to corrosion.

Weight and Ergonomics

Aluminum alloy has a density of only 2.70 g/cm³, approximately one-third that of stainless steel (8.0 g/cm³). Consequently, aluminum handles are lightweight and easy to install, significantly reducing operator fatigue during use. They are particularly suitable for large panels or portable enclosures. Conversely, stainless steel handles are heavier, offering a solid feel, and are often used in high-end equipment or applications requiring greater inertia and a sense of stability.

Cost and Full Lifecycle

From a procurement and manufacturing perspective, aluminum alloys offer lower material costs and reduced processing expenses, resulting in more economical initial investments. Stainless steel carries higher material and processing costs but delivers superior durability and longevity, reducing replacement and maintenance frequency over time. This yields better cost-effectiveness throughout the entire lifecycle. Considering return on investment, adopting a Total Cost of Ownership (TCO) approach during decision-making is recommended to balance upfront costs against long-term durability.

Decision Comparison

Strength and Weight Comparison – Stainless Steel vs Aluminum Alloy Handles

| Category | Stainless Steel | Aluminum Alloy |

|---|---|---|

| Strength | ★★★★★ High (540–750 MPa) | ★★★ Moderate (around 310 MPa) |

| Corrosion Resistance | ★★★★★ Excellent (Grade 316 withstands seawater) | ★★★ Fair |

| Weight | ★★ Heavier | ★★★★★ Lightweight (about one-third the weight) |

| Maintenance | ★★★★★ Low maintenance | ★★★ Requires upkeep after anodizing |

| Cost | ★★ Higher cost | ★★★★★ Budget-friendly |

| Best Use | Outdoor, heavy-duty, or hygienic environments | Indoor, lightweight, or cost-efficient applications |

Application Scenarios and Selection Guide

Application Scenarios of Stainless Steel and Aluminum Handles

Stainless Steel Handle Applications

Stainless steel handles are the top choice for environments demanding high corrosion resistance and cleanliness. Common applications include outdoor cabinets, ship decks, chemical plants, and food processing facilities—where high humidity or corrosive agents require the use of 304 or 316 stainless steel. Medical instrument housings and pharmaceutical equipment also frequently utilize stainless steel handles due to stringent hygiene and corrosion standards.

In addition, stainless steel handles are widely used in railways, subways, heavy machinery, and public facilities. These applications involve frequent operation, vibration, and impact, where stainless steel construction ensures long-term structural stability, safety, and reliability.

Aluminum Alloy Handle Applications

Aluminum handles are ideal for applications that prioritize lightweight design or cost efficiency. They are commonly used in electronic enclosures, automation control cabinets, laboratory equipment, and portable cases—where environments are only mildly corrosive, and weight reduction is critical.

By significantly lowering overall weight, aluminum alloy handles improve usability and ease of installation, particularly in indoor applications. They are also favored for equipment that requires effective heat dissipation or electrical conductivity, such as power distribution cabinets and machine tool control panels.

In summary, aluminum alloy handles are the preferred choice in environments with low corrosion risk, where minimizing weight and cost is more important than achieving maximum structural strength.

Selection Comparison

- High strength requirements: Stainless steel outperforms aluminum; choose stainless steel.

- High corrosion resistance: Stainless steel is more suitable (especially 316 marine-grade).

- Lightweight and cost priority: Aluminum alloy is more suitable.

- Maintenance frequency considerations: If regular surface treatment is inconvenient, choose stainless steel for superior corrosion resistance; if anodizing is feasible and lower cost is desired, aluminum alloy can be used.

Standards, Testing, and Quality Control

Material Standards and Certifications

When selecting materials, ensure compliance with relevant standards and test certifications.

Stainless steel handles should conform to ASTM A240/A240M, specifying chromium and chromium–nickel stainless steel plate, sheet, and strip.

Aluminum handles should meet ASTM B209/B209M, covering aluminum and aluminum-alloy sheet and plate for general engineering applications.

Performance and Durability Testing

Performance testing should follow standards such as EN 1906 (lever handles and knobs — requirements and test methods) or ANSI/BHMA A156.9 (cabinet hardware) for mechanical durability, and ISO 9227 for corrosion resistance throughout the rated service life.

Quality Control and Traceability

Quality control emphasizes supply-chain traceability and the importance of factory inspection. The State Administration for Market Regulation (SAMR) mandates establishing a quality traceability system for key industrial products that enables “source verification, destination tracking, and accountability tracing.”

Procurement Verification

Prior to procurement, verify material test reports and factory test records provided by suppliers to ensure that material grades and performance indicators meet required specifications.

Conclusion and Selection Recommendations

Stainless steel handles deliver superior strength, corrosion resistance, and durability—ideal for outdoor, marine, or high-hygiene industrial environments where exposure to moisture or chemicals is frequent. Aluminum handles offer lightweight, cost-effective performance and are easier to machine, making them suitable for applications focused on weight or budget efficiency. Selecting the right material ensures the reliability and long-term performance of industrial equipment.