HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Industrial enclosures house sensitive electronic components, making the reliability of their door locks directly critical to enclosure security. Choosing the wrong lock can have serious consequences: poor sealing allows moisture and dust to enter, potentially causing equipment short circuits; vibration can loosen the lock, creating hazards; inadequate security may lead to theft, unauthorized access, or other safety incidents. Selecting the right paddle latch is therefore crucial to ensuring long-term stable operation of your enclosure. This guide provides a detailed analysis of paddle latch structure, types, and selection criteria to help engineers and procurement teams make informed decisions.

What Is a Paddle Latch? — The “Invisible Guardian” for Industrial Applications

A paddle latch, also called a flat paddle lock, is a cam-operated locking mechanism featuring a paddle-shaped lever. Typically installed flush with the enclosure door panel, it appears externally as a flat “paddle plate.” Pressing or pulling the paddle activates the internal locking mechanism, allowing the door to open.

Its simple internal structure is reliable, usually relying on a strong spring to keep the latch locked, requiring manual operation of the paddle to unlock. Advantages include:

- Ease of use: operable with one hand.

- Durability: simple, robust design with low maintenance requirements.

- High security: flush design reduces vulnerability to tampering.

Basic Anatomy of a Paddle Latch

Paddle/Handle: Paddle-shaped handle, often flush-mounted with the door panel. Pressing or lifting completes the lock/unlock action. Materials include stainless steel, zinc alloy, or nylon.

Housing: Main lock body that holds springs, latch bolts, and other components; secured within the door cutout.

Cylinder: Some models include a key cylinder for added security; non-locking types omit this component.

Cam/Pawl: Rotates or moves with the handle to secure the door panel to the frame. Some models have adjustable cams to fit different door thicknesses or locking ranges.

Gasket: Rubber or silicone seal between the latch/lock body and door frame to improve environmental protection and security rating.

How Paddle Latches Work

- Standard Paddle Latch: Provides basic on/off locking functionality. When closed, the latch engages the door frame under spring tension.

- Compression Paddle Latch: Upon closing, the latch retracts inward an additional 3–6 mm, compressing the gasket to improve dust and water resistance and prevent vibration-induced loosening.

Flush-mounted paddle latches offer a smooth, discreet appearance compared to traditional L- or T-shaped handles, providing enhanced safety and reliability. They are often used in critical protection scenarios, such as cabinet doors.

Unique Advantages of Paddle Latches: Why Engineers Prefer Them

Ergonomic Design: Wide paddle handle allows single-handed operation, even when wearing gloves.

Low Profile, High Security: Flush-mounted design minimizes protrusions, reducing the risk of snagging or collisions, suitable for confined or high-traffic environments.

Robust Durability: Simple structure with strong springs and high-strength materials withstands frequent industrial use with minimal maintenance.

Professional Aesthetics: Flush-mounted design maintains smooth cabinet surfaces, improving appearance and vandal resistance.

Note: Functional differences between paddle latches are significant; selection should be based on specific requirements.

Paddle Latch Types: Which One Fits Your Needs?

By Function: Standard vs. Compression

Standard Paddle Latch: Secures the door panel without additional compression force. Suitable for indoor electrical cabinets, toolboxes, or low-protection applications.

Compression Paddle Latch: Includes inward retraction (3–6 mm) upon closing, compressing the sealing gasket. Enhances dust and water resistance, eliminates vibration loosening and noise, ideal for outdoor enclosures, NEMA 4/IP65-rated applications, or vibration-prone environments like vehicles or generator cabinets.

By Security Mechanism

Non-locking: Provides basic lock functionality without a keyed cylinder. Suitable for internal cabinets or low-security areas.

Keyed-Alike (KA): One key opens all locks of the same model, convenient for maintenance teams.

Keyed-Different (KD): Each lock has a unique key, suitable for multi-user or multi-department environments.

Padlock-Compatible: Includes a padlock hole on the lock body, allowing the use of external padlocks. Supports Lockout/Tagout (LOTO) safety protocols and flexible security levels.

By Locking Points: Single-Point vs. Multi-Point

Single-Point Lock: One latch bolt secures the door, suitable for smaller panels.

Multi-Point Locking: Central handle engages two or more longitudinal bolts, securing the door at multiple points. Improves rigidity, distributes load, and enhances security and protection.

Ultimate Selection Guide: 7 Key Decision Criteria

Material Selection

| Material | Properties & Corrosion Resistance | Typical Applications |

|---|---|---|

| 304 Stainless Steel | 18% Cr + 8% Ni, good corrosion resistance, moderate cost | Indoor industrial use, mildly humid environments, food processing |

| 316 Stainless Steel | 2–3% Mo, marine-grade, excellent chloride/salt spray resistance, higher cost | Coastal areas, chemical plants, pharmaceuticals, wastewater treatment |

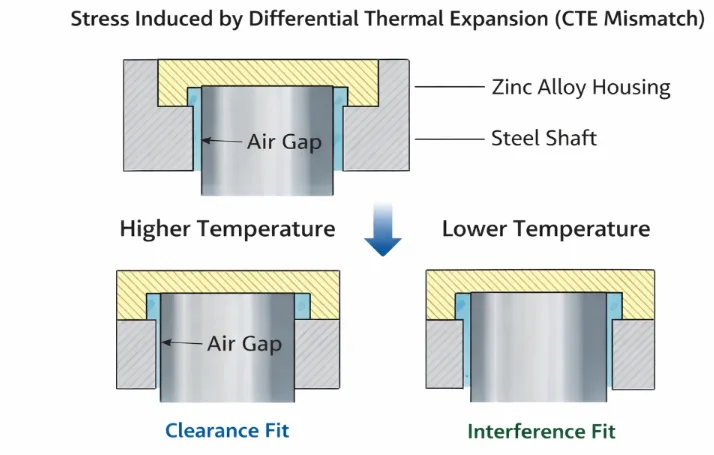

| Zinc Alloy | Low cost, die-cast, coated for corrosion resistance, prone to rust if coating damaged | Dry, non-corrosive environments, lightweight cabinets, toolboxes |

| Plastic/Nylon | Lightweight, electrically insulating, chemically stable, low mechanical strength | Specialized insulation, lightweight instrument enclosures |

Choose material based on the operating environment. For high-corrosion environments, prioritize 316 stainless steel; for indoor use, 304 suffices.

Protection Rating (IP/NEMA)

IP Ratings (IEC 60529):

- IP65: Dust-tight; withstands low-pressure water jets.

- IP67: Dust-tight; can survive temporary immersion in water.

NEMA Ratings (US):

- NEMA 4/4X: Protection against windblown dust and rain; 4X adds corrosion-resistant material.

Compression mechanisms and high-quality gaskets (EPDM, silicone) significantly enhance protection levels.

Security Level

Evaluate equipment value and site environment. Consider:

- Flat-Key Locks: Economical, standard security.

- Barrel/Cylinder Locks: Higher pick resistance.

- High-Security Locks (Medeco, Abloy): Drill- and pry-resistant for high-risk environments.

Large walk-in cabinets or cold storage doors may require internal release mechanisms for safety compliance.

Dimensions and Cutouts

Grip Range: Effective closing distance; calculate based on door panel thickness, frame gap, and gasket thickness.

Door Panel Thickness: Ensure lock fits within specified thickness range; otherwise, use shims or custom locks.

Cutout Dimensions: Verify compatibility with standard sizes, especially when replacing older locks.

Latch/Cam Selection

Shape: Straight, single-curved, or double-curved depending on door engagement.

Material: High-strength steel or stainless steel.

Adjustability: Some latches allow fine-tuning via threaded adjustment.

Operation and Direction

Check door opening direction (left/right). Some models are reversible to simplify inventory and installation.

Industry Compliance

- Environmental: RoHS/REACH compliance.

- Certifications: UL 50/50E, UL 508A, CE, CSA.

- Vibration Durability: SAE J1455 standard for mobile/vehicle enclosures.

Practical Applications

Telecom & 5G Base Stations: 304 stainless steel compression paddle latch, IP66/NEMA4X, high-security cylinder.

RV, Fire Truck, Special Vehicle Toolboxes: Compression latch, zinc alloy or stainless steel, keyed cylinder, silicone seals optional.

Data Centers & Electrical Cabinets: Multi-point locking, KA configuration or electronic access locks.

Marine/Coastal HVAC: 316 stainless steel compression paddle latch, IP67-rated gasket, tested for salt spray.

Installation & Maintenance

- Installation: Precise cutout, moderate torque on screws, gasket flat and undistorted.

- Maintenance: Keep surfaces clean, lubricate cylinder with graphite powder, inspect gasket for aging.

5 Common Mistakes When Selecting Paddle Latches

- Focusing on appearance while ignoring environment.

- Incorrect grip range measurement.

- Underestimating vibration effects.

- Ignoring protection rating (IP).

- Prioritizing low purchase cost over durability.

Conclusion

Proper paddle latch selection ensures long-term security, sealing integrity, and minimal maintenance. Material, compression, security, and dimensional compatibility all affect performance. Choose based on the harshest expected environment to maximize protection and ROI.

Call to Action

Browse our paddle latch catalog or contact our hardware experts for a free consultation to ensure the right solution from the start.

FAQ

Q1: How to distinguish 304 vs 316 stainless steel paddle latches?

A1: 304: 18% Cr + 8% Ni, moderate corrosion resistance. 316: +2–3% Mo, marine-grade, excellent salt/chloride resistance.

Q2: What is a compression-type paddle latch? Is it necessary?

A2: Tightens door and gasket for dust/water resistance; prevents vibration loosening. Recommended for outdoor, weather-exposed, or vibration-prone applications (IP65/IP66).

Q3: How to measure the grip range?

A3: Measure door panel + frame thickness minus lock body projection; consult manufacturer charts for short/long arm or adjustable latches.

Q4: What does IP65 mean?

A4: Dust-tight (6), withstands low-pressure water jets (5). Common for outdoor cabinets.

Q5: Can one key open all locks? (KA vs KD)

A5: KA: One key opens all; KD: Each lock has a unique key.