HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Corrosion and Degradation of Outdoor Equipment Handles

A pull handle on an outdoor generator enclosure rusts and seizes after months of rain exposure; a safety latch on a chemical processing machine fails due to acidic fume corrosion. These seemingly minor handle failures can conceal equipment malfunctions or safety hazards, ultimately driving up maintenance and operational costs.

Standard carbon steel or zinc alloy handles quickly fail under chemical exposure, high humidity, and extreme temperature fluctuations. The solution lies in selecting “weatherproof”/“corrosion-resistant” handles specifically engineered for harsh industrial environments.

This guide delves into the corrosion and weather resistance capabilities of different materials, common application scenarios, and key selection criteria—empowering you to make the right decision once and avoid frequent replacements and hidden risks.

So, what truly defines “weather-resistant”?

Decoding Terminology: The Difference Between “Weather-Resistant” and “Corrosion-Resistant”

What is “Weather Resistance”?

“Weather resistance” refers to a handle’s ability to withstand natural environmental challenges, including sunlight UV rays, rain/snow/freezing, high/low temperature cycles, and wind/dust/sand exposure.

Years of UV exposure can cause plastic materials to become brittle and chalky; prolonged moisture or freezing can lead to metal coatings fading and cracking, while water ingress may cause internal components to rust or freeze and expand.

Common environmental “enemies” include:

- UV rays: Accelerate the aging of organic materials (like plastics and coatings), causing them to lose flexibility;

- Moisture (rain, snow, fog): Rapidly oxidizes and rusts unprotected metals; freezing can cause structural damage to components;

- Extreme temperatures: Alternating high and low temperatures cause repeated thermal expansion and contraction, accelerating fatigue failure;

- Dust and grime: Accumulated dirt weakens surface protective layers, triggering or accelerating corrosion.

These combined effects cause ordinary handle materials to degrade rapidly in outdoor environments.

For instance, plastics without specialized formulations eventually become brittle after prolonged outdoor exposure, developing powdery surface cracks; powder coatings lose color when their protective layer deteriorates.

What is “Corrosion Resistance”?

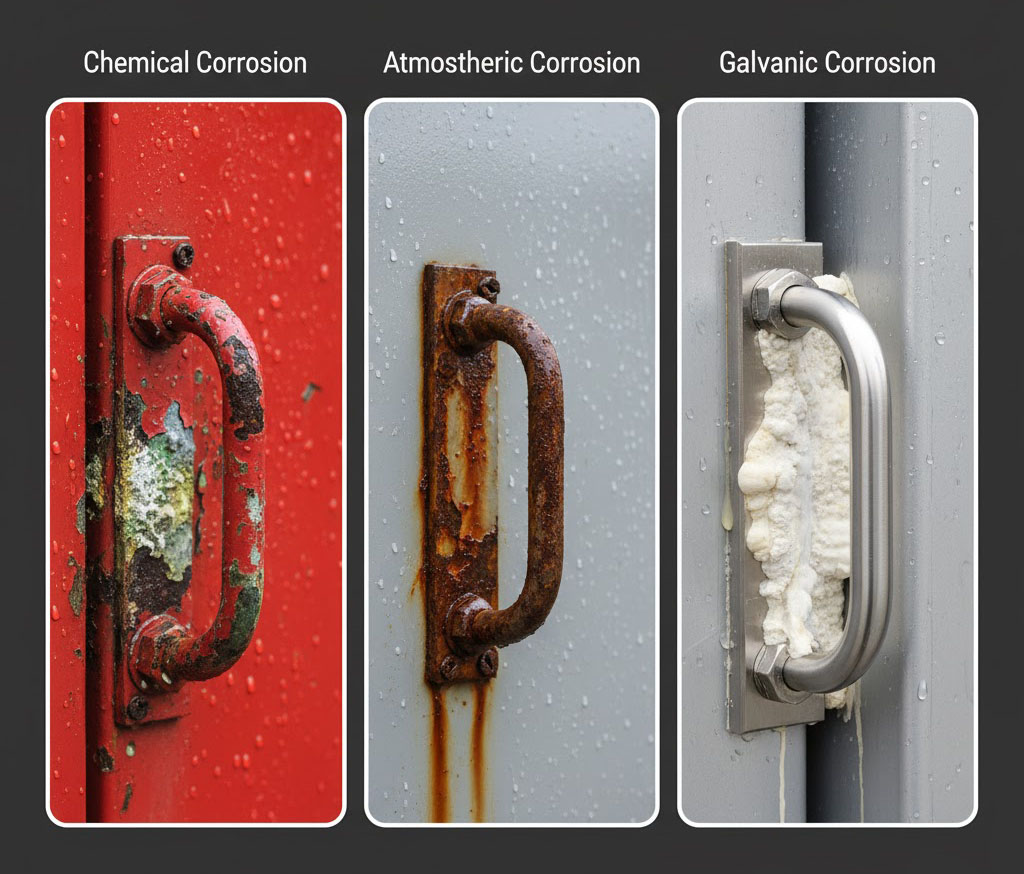

Three Key Types of Corrosion Chemical, Atmospheric, and Galvanic

“Corrosion resistance” focuses on withstanding chemical attack. Common forms include:

- Atmospheric corrosion: Oxidation (rusting) caused by moisture and oxygen in the air.

- Chemical corrosion: Damage caused by exposure to acids, alkalis, solvents, or cleaning agents.

- Galvanic corrosion (electrochemical corrosion): When two dissimilar metals come into contact in a conductive medium (like water or saltwater), the metal with lower potential (the metal anode) corrodes more rapidly.

- Salt spray corrosion: In coastal areas and winter de-icing salt environments, salt aerosols accelerate metal pitting and uniform corrosion.

Chloride-laden environments are particularly lethal to stainless steel; for instance, 304 stainless steel rapidly develops pitting corrosion in salt spray.

Why Both?

Many scenarios demand simultaneous resistance to both atmospheric and chemical corrosion. For example, coastal door handles must withstand intense UV radiation and salt spray erosion, while outdoor cabinets in chemical plants require protection against rain and acid/alkali splashes.

This demands handles with both excellent weather resistance and superior corrosion resistance.

Material Deep Dive: Your Shield Against the Elements

There is no “universal” material—only the best choice for your specific environment.

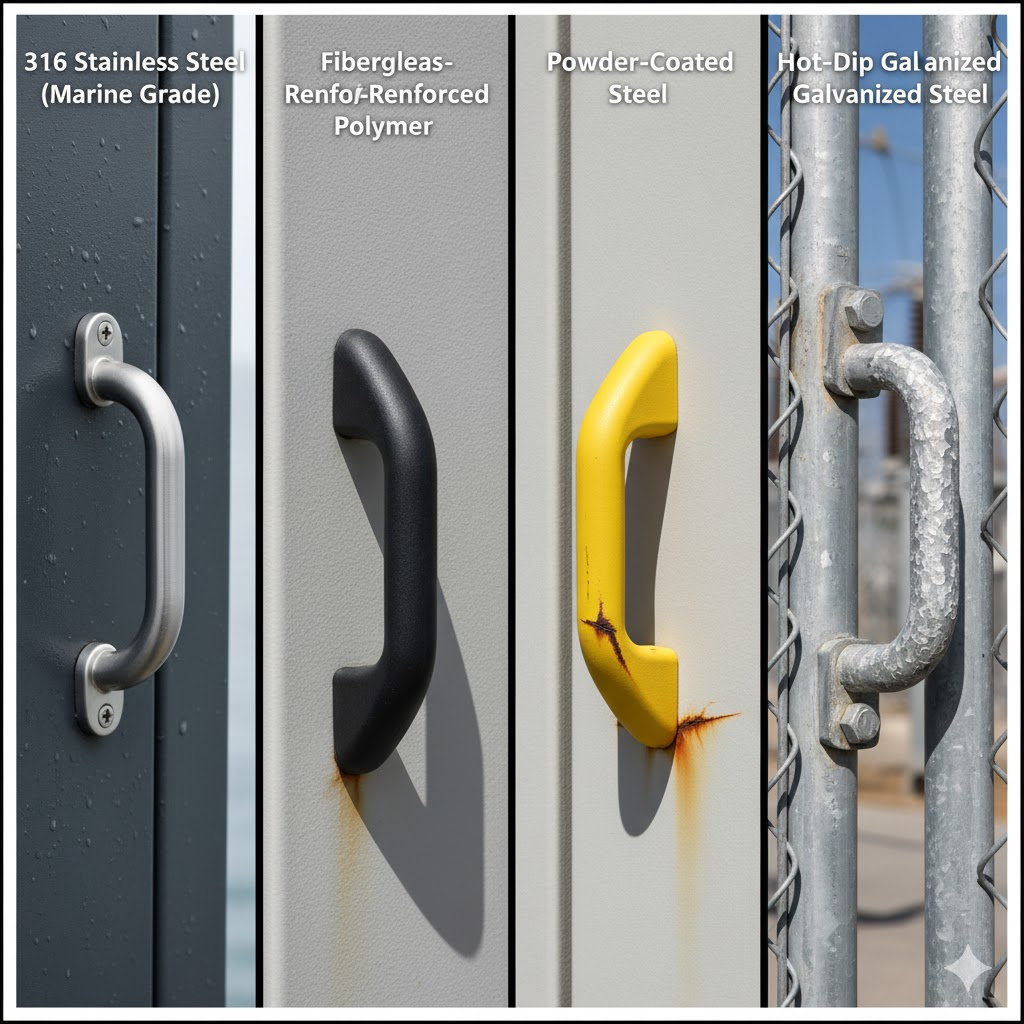

Comparison of Corrosion-Resistant Materials: 316 Stainless Steel vs. Nylon-Coated Steel

Stainless Steel: The Corrosion-Resistant Champion

- 304 Stainless Steel (Standard Grade): Performs well in most general outdoor environments. Its chromium content forms a passivated oxide layer on the surface, preventing oxidation.

However, 304 grade has limited resistance to chlorides. Exposure to saltwater or bleach environments can lead to pitting corrosion and brown rust spots. - 316 Stainless Steel (Marine Grade): Incorporates 2–3% molybdenum over 304, significantly enhancing the passivation film’s stability against chlorides.

This makes it exceptional in high-chloride environments like oceans, pools, and de-icing salt applications, becoming nearly the sole choice for marine and chemical settings. Its drawback is a notably higher cost than 304. - Surface Treatment: To further enhance corrosion resistance, stainless steel surfaces can undergo passivation or electropolishing.

Passivation removes processing contaminants to restore the oxide film’s integrity; electropolishing creates a smoother, finer surface that further resists corrosion, commonly used in food and medical industries.

High-Performance Polymers and Composite Materials

These handles are not ordinary plastics but engineered plastics and composites.

Examples include glass-fiber reinforced nylon (GF nylon), polypropylene (PP), and polyvinyl chloride (PVC):

- Advantages: Plastics inherently resist corrosion (zero corrosion). They are lightweight, and many possess excellent electrical insulation properties.

Special formulations can impart UV resistance. Certain nylons and PP exhibit strong chemical resistance, even withstanding most acidic and alkaline cleaners. For instance, glass-filled nylon offers high rigidity, excellent heat resistance, and superior dimensional stability. - Disadvantages: Typically lower strength than metal, limiting load-bearing capacity; may degrade under prolonged exposure to intense UV light without dedicated UV stabilizers in the formulation; may convey a “cheap” feel or appearance compared to metal, requiring careful selection.

Coated and Treated Metals

- Powder-coated steel/aluminum: Powder coatings are electrostatically sprayed and cured at high temperatures to form a durable, colored protective layer.

Powder coatings offer an attractive appearance and excellent weather resistance (strong adhesion, environmentally friendly, non-toxic).

Weaknesses: Once the coating is scratched or peeled, the exposed base metal corrodes rapidly.

Therefore, the coating surface must remain undamaged. Cracks or scratches appearing during daily use require immediate repair. - Hot-dip galvanizing: A sacrificial zinc layer is applied to the steel surface. This zinc layer physically isolates the metal from the corrosive environment. Additionally, since zinc is more reactive than steel, it corrodes before the steel substrate even if the coating is damaged.

Hot-dip galvanizing provides exceptionally durable protection with excellent scratch resistance. Disadvantages include a rough surface finish (generally unattractive appearance) and potential deformation of thin-walled components during galvanizing (unsuitable for applications with strict dimensional requirements). - Anodized Aluminum: Electrochemically oxidizes aluminum to form a hard oxide layer on the surface.

Advantages include light weight, excellent corrosion resistance, and a modern matte finish.

However, it offers lower strength than stainless steel. Scratches compromise the protective layer, and it is only suitable for aluminum and specific aluminum alloys.

Other Alloys: Brass and Bronze

- Bronze (copper-tin alloy): Contains minimal zinc, primarily composed of copper and tin, making it highly suitable for marine environments.

It exhibits minimal dezincification in seawater and exceptional corrosion resistance. Copper surfaces develop a green oxide layer (verdigris), which, though mottled in appearance, provides additional protection.

Bronze is expensive and generally reserved for highly demanding marine applications. - Brass (copper-zinc alloy): Features a traditional metallic luster and was historically common in marine fittings.

Moderate zinc content enhances strength, but brass is susceptible to dezincification corrosion in seawater, leading to material embrittlement over time.

Brass surfaces naturally develop verdigris, though regular polishing is required to maintain appearance.

Compared to bronze, brass is less expensive but incurs higher maintenance costs.

Material Comparison Table

| Material | Corrosion Resistance | UV Resistance | Strength | Cost |

|---|---|---|---|---|

| 304 Stainless Steel | Good (general atmospheric environments) | Excellent (UV-resistant) | Very high | Moderate |

| 316 Stainless Steel | Superior (optimal in saline environments) | Excellent | Very high | High |

| Fiberglass-Reinforced Nylon | Completely rustproof (plastic material) | Highly possible (requires UV stabilizers) | Moderate | Low |

| Powder-Coated Steel | Good (when coating is intact) | Very high | Very high | Low |

The above comparison table summarizes the performance of four common materials in terms of corrosion resistance, UV resistance, strength, and cost.

Applications and Case Studies

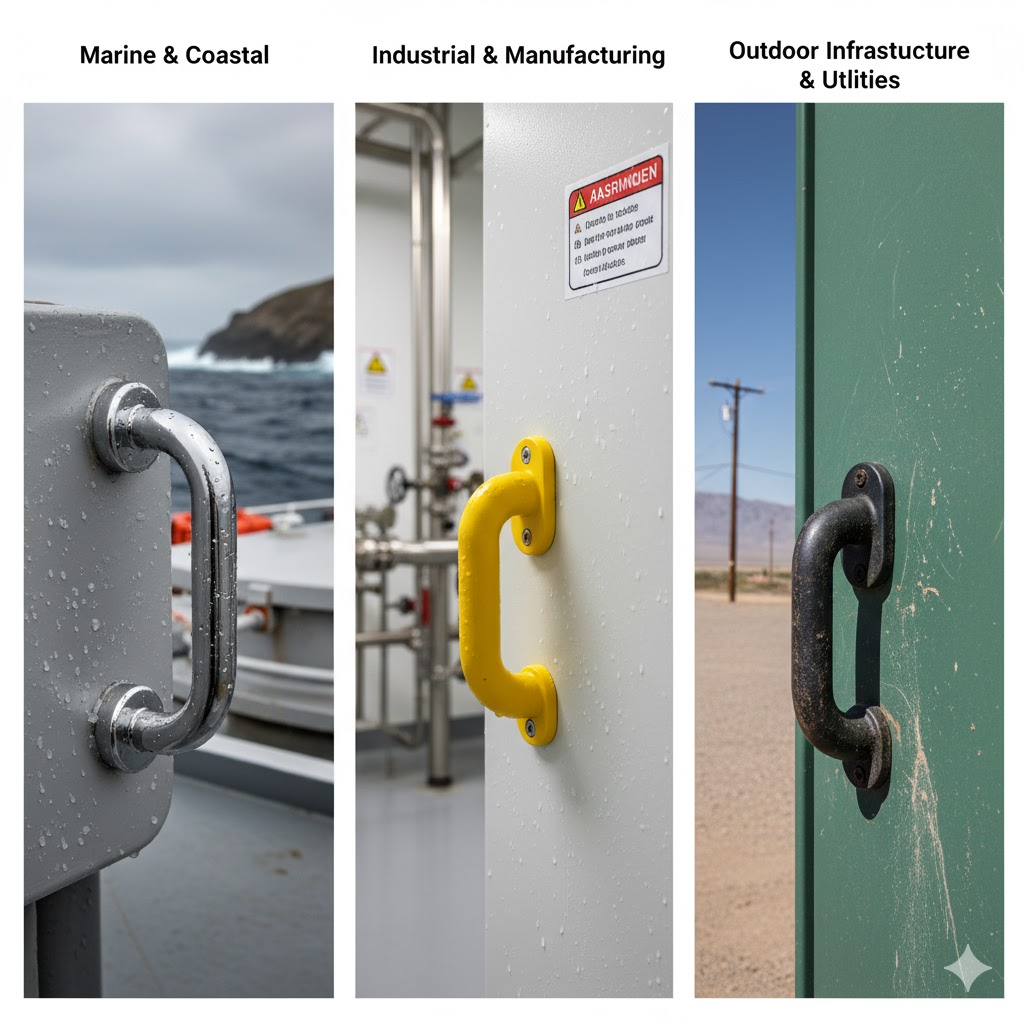

Handle Material Performance in Different Environments

Different environments pose distinct challenges, requiring different material solutions.For a broader overview of handle classifications and design types suited to industrial environments, see our Industrial Handles Selection Guide

Common environmental “enemies” include:

- Marine and Coastal: Primary threats are intense salt spray and high humidity. 316 stainless steel (preferred) or bronze are recommended for optimal corrosion resistance in seawater environments. Typical applications include ship railings, hatch handles, dock hardware, and door handles for seaside villas.

- Industrial & Manufacturing: Enemies include diverse chemicals, high temperatures, and frequent washing operations. Recommended materials are 316 stainless steel (high chemical resistance) or engineering plastics like polypropylene (acid/alkali resistance). Applications include chemical plant safety cabinets, equipment access doors, and handles for food processing machinery (requiring resistance to cleaning agent corrosion).

- Outdoor Infrastructure & Utilities: Enemies include UV radiation, rain/snow, freezing temperatures, and thermal shock. Recommended materials include 304 stainless steel, UV-stabilized high-grade plastics, and reliable powder-coated steel. Common applications include telecom enclosures, substation fence gates, outdoor storage lockers, and park fitness equipment.

- Transportation: Primary threats include road salt, moisture, vibration, and weather fluctuations. Recommended materials: 304/316 stainless steel and heavy-duty nylon handles. Applications: RV storage compartment handles, utility vehicle/truck toolbox handles, external handles for fire trucks and ambulances.

The Ultimate Buying Guide: 7 Steps to Selecting the Perfect Handle

For more detailed insights into handle materials, installation methods, and ergonomic considerations, refer to our Comprehensive Industrial Handle Design Guide

- Assess the “Enemy”: Identify primary corrosion sources. Is it salt spray, water, acidic/alkaline chemicals, or UV exposure?

- Determine Load Requirements: How much pulling force must the handle withstand? Is it for heavy doors or small box lids?

- Check Mounting Method and Fasteners: Fastener materials must be equally corrosion-resistant to prevent galvanic corrosion.

- Evaluate ergonomics: Will gloves be worn during operation? Is a comfortable grip required?

- Review industry ratings: Such as IP65 (IEC 60529 standard) or NEMA 4X.

- Consider appearance and aesthetics: Does it need to match equipment or architectural style?

- Calculate total cost of ownership (TCO): High-quality handles last longer, offering greater long-term savings.

Maintenance: Myths vs. Reality

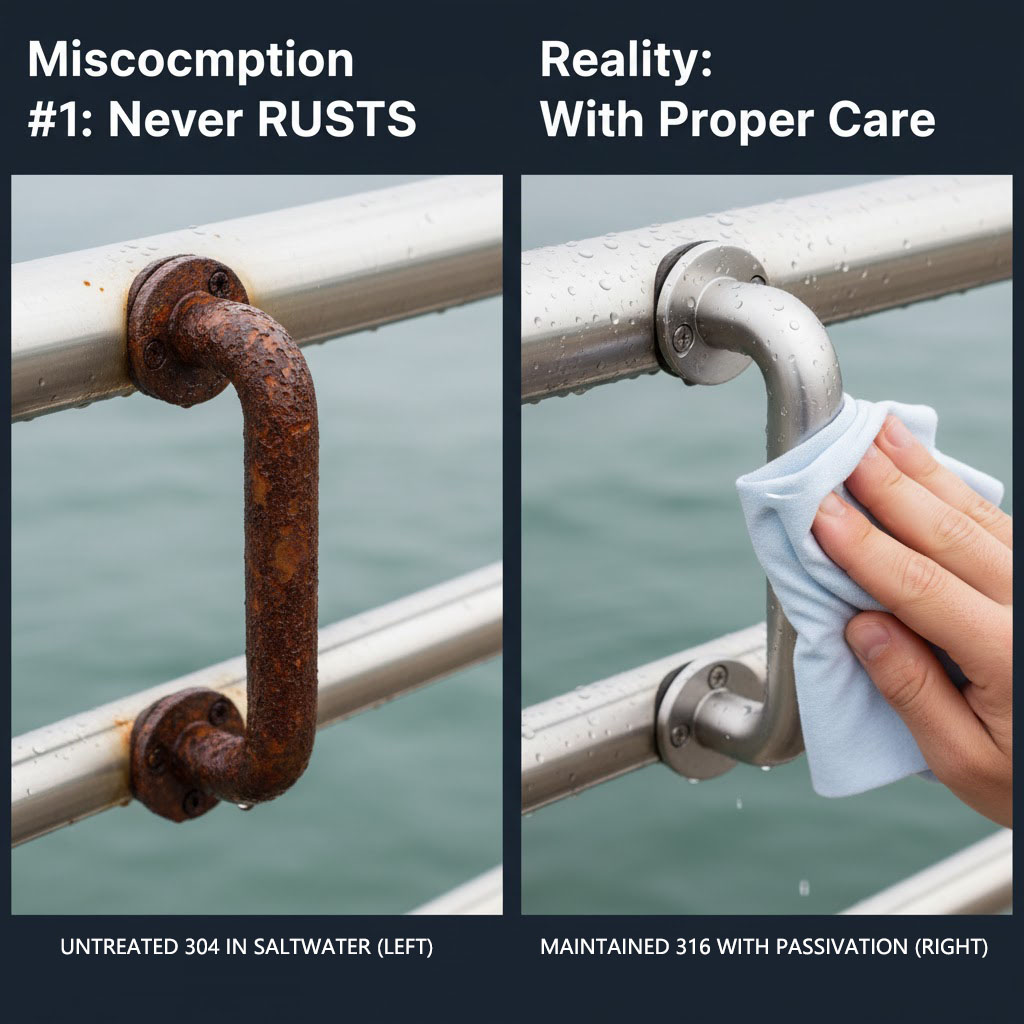

Stainless Steel Myth vs. Reality Untreated 304 in Saltwater (Left) vs. Maintained 316 with Passivation (Right)

Common Misconception #1: “Stainless steel” means it will never rust.

Reality: Stainless steel is highly resistant to rust, but not entirely rustproof. Grade 304 develops brown rust spots quickly in salt spray environments; Grade 316 is more durable but may discolor with prolonged exposure.

How to clean stainless steel: Use mild soapy water and wipe along the metal grain. Never use steel wool or bleach. Regularly apply specialized stainless steel cleaners or passivators to repair minor scratches and restore the protective layer.

Maintaining Coatings and Polymers:

Periodically inspect powder-coated surfaces for cracks or scratches, repairing them immediately upon discovery. Plastic handles can be cleaned with mild detergent and periodically sprayed with UV protectant to delay aging.

Conclusion: Make the Right Choice the First Time

In harsh environments, success depends on preparation—failing to plan is planning to fail.

Selecting the right materials (e.g., 316-grade stainless steel for coastal use, UV-coated handle surfaces, UV-stable plastics for high-light environments) and sound design are key to ensuring safe, reliable handles with the lowest long-term costs.

Handles are not ordinary consumables; they are vital safety components for equipment, vessels, or facilities—worth getting right the first time.

Ready to find handles that won’t let you down?

Explore our weather-resistant and corrosion-resistant handle series now, or contact our hardware experts for a free consultation tailored to your specific needs!

Frequently Asked Questions

Q1: Is 304 stainless steel truly unsuitable for coastal areas?

A: Not recommended. While 304 stainless steel won’t rust instantly like carbon steel, it will develop unsightly brown rust spots and pitting in high-salt coastal environments.

Q2: Which is better: powder-coated handles or stainless steel handles?

A: It depends on the environment. Powder-coated handles offer good weather resistance when the coating is intact and come in multiple colors, but exposed steel rusts quickly once the coating is damaged.

In contrast, 316 stainless steel resists corrosion even when scratched, offering superior inherent corrosion resistance. For high-wear or marine environments, stainless steel handles (especially 316 grade) are safer and more reliable.

Q3: What is “galvanic corrosion,” and how can I prevent it?

A: Galvanic corrosion occurs when two dissimilar metals (e.g., aluminum and stainless steel) come into contact in a moisture-containing environment, especially saltwater. The metal with lower electrical potential (anode) corrodes more rapidly, creating a “battery effect” between the metals.

Prevention methods: Use fasteners made of identical or compatible materials whenever possible (e.g., pair 316 stainless steel handles with 316 stainless steel bolts). If mixing metals is unavoidable, isolate them using non-conductive materials like nylon washers.

Q4: How often should I inspect my outdoor handles?

A: Inspect at least 1–2 times annually, ideally conducting comprehensive checks in spring and fall. Inspect for: loose fasteners, damage to handles or coatings, rust formation, or peeling.

Address any issues promptly to ensure handles are in good condition before extreme weather arrives.

Q5: What exactly does “marine grade” mean?

A: “Marine grade” is essentially a marketing term, typically referring to materials offering the highest corrosion resistance in seawater environments.

In the realm of metal handles, this almost invariably denotes 316-grade stainless steel or copper-bronze alloys, as they provide the best defense against saltwater corrosion.