HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Stainless steel hinges are key connectors in industrial cabinet doors, equipment housings, architectural hardware and other areas.

They are responsible for supporting the opening and closing of door panels, which directly affects the safety and durability of equipment.

Customized stainless steel hinges can be accurately adapted to non-standard requirements (such as heavy-duty cabinets with high load-bearing capacity, corrosion-resistant medical equipment, non-standard hole spacing for transportation facilities), installation without adjustment, according to industry statistics can reduce the assembly time by 30%, significantly improving production efficiency.

According to industry statistics, customized solutions can reduce assembly time by 30%.

In this article, we’ll explain how to choose a reliable stainless steel hinge manufacturer to ensure you get a high-performance customized product.

Why Choose Custom Size Stainless Steel Hinges?

Standard Size vs. Customized Size

Standard Hinges

- Suitable for general-purpose scenarios, but the following problems may occur when encountering special needs:

- Difficult to install due to mismatch of holes

- Insufficient load-bearing causes deformation of door panels

- Risk of corrosion due to substandard material

Advantages of Customized Stainless Steel Hinge

- Design thickness and structure according to the actual load

- Adjust the hole distance, shaft diameter and other parameters to fit the mounting surface

- Choose a higher grade of stainless steel (e.g. 316L) to cope with harsh environments

What Scenarios Require Customization?

- Heavy-duty doors (e.g. power cabinets, industrial ovens)

- Non-standard hole spacing (retrofit of old equipment or special design)

- High corrosion resistance needs (coastal areas, chemical plants, medical equipment)

Customer Demand Cases

- Food machinery factory: need to customize food-grade 316 stainless steel hinges, surface electrolytic polishing easy to clean

- Railroad equipment manufacturer: required removable hinges for easy maintenance of carriage doors

- Automation equipment company: to develop hinges with damping function to reduce noise

Key Features of High Quality Stainless Steel Hinges

Material Selection

- 304 stainless steel: cost effective and suitable for most interior environments

- 316 stainless steel: 2-3% molybdenum, resistant to chloride ions, recommended for coastal or chemical environments

Surface Treatment Process

| Process Type | Feature | Applicable Scene |

|---|---|---|

| Mechanical polishing | Smooth surface | Food, medical equipment |

| Electrolytic polishing | Removal of metal impurities | High cleanliness requirements |

| Passivation | Enhanced oxide film | Extended outdoor service life |

Structural Design

- With damping hinge: control the closing speed of the door to protect the precision equipment

- Spring hinge: automatic return function, suitable for frequent opening and closing of the door

- Detachable design: easy to maintain or replace at a later stage

Performance Standard

- Corrosion resistance: Passed 48 hours neutral salt spray test (ASTM B117 standard)

- Load bearing capacity: Static load up to 80kg per hinge (according to ISO 9001 quality control)

- Life test: 100,000 times opening and closing without deformation (refer to EN 1935 industry standard)

How to Choose a Reliable Customized Stainless Steel Hinge Manufacturer?

Technical Capability Assessment

- Does it support drawing optimization or 3D modeling?

- Can you provide samples within 5 working days?

Production Process Standard

- Machining equipment: CNC machine tools (CNC) to ensure ±0.1mm accuracy

- Welding technology: Argon arc welding reduces thermal deformation and maintains structural strength

- Stamping technology: continuous mold stamping to improve efficiency and reduce unit cost

Quality Control System

- Certification requirements: ISO 9001 certified factories are preferred

- Testing process: full-size testing + random sampling salt spray test

- Documentation support: Provide material reports and certificates of conformity

Service Flexibility

- Do you accept small orders (e.g. 100 pieces)?

- Can you provide international logistics and customs clearance documents?

Application Scenarios of Customized Stainless Steel Hinge

- Industrial automation: robotic arm guard door hinge

- Outdoor cabinet: waterproof case for 5G base station

- Medical equipment: operating table hidden hinge

- Transportation facilities: special hinge for high speed rail luggage compartment door

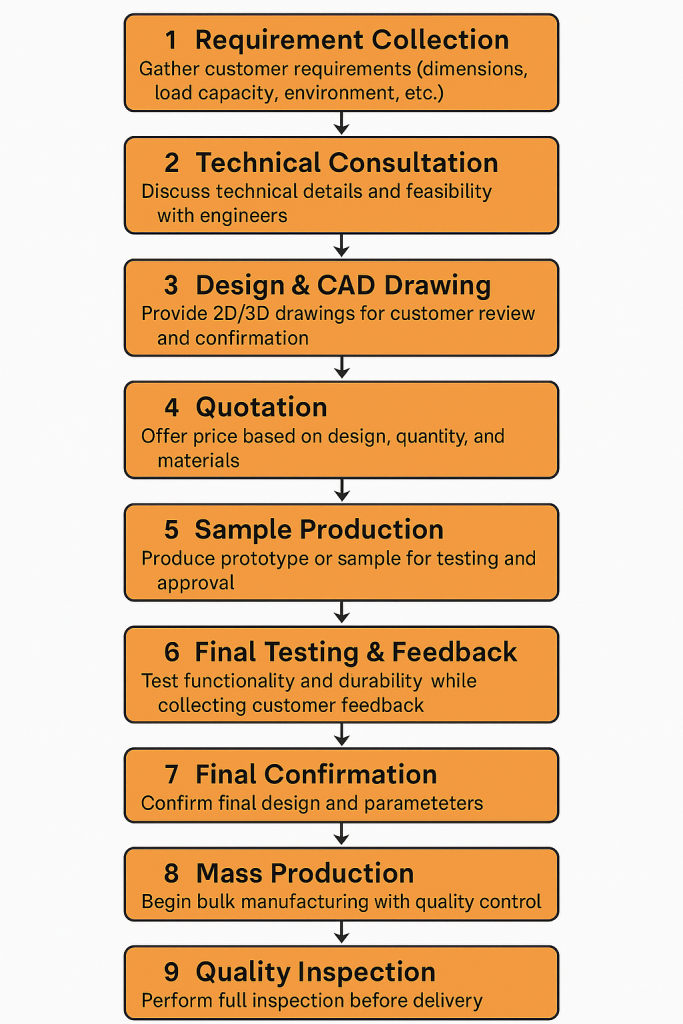

How to Start Your Customized Order?

Customized Parameter List

- Mounting hole distance (accurate to 0.1mm)

- Plate thickness (1.5-6mm optional)

- Torque requirement (with damping model to be specified)

- Surface treatment grade (e.g. Ra≤0.8μm)

Conclusion

Choosing a professional stainless steel hinge manufacturer not only solves the problem of non-standard design, but also reduces the cost by optimizing the structure. We provide full-process support from drawing design to mass production to ensure that your project moves forward efficiently. Contact us now for a free technical consultation and quick quote!

Frequently Asked Questions

Q: How long does it take for customized delivery?

A: 3-5 days for samples, 7-15 days for mass production (adjusted according to quantity).

Q: What is the minimum order quantity?

A: We support 100pcs small quantity customization, no mold fee.

Q: What material certificates are provided?

A: SGS material inspection report and RoHS certification can be attached.