HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Introduction: Failure Scenario Analysis

Consider these failure scenarios: A user opens an expensive industrial device, only for the heavy access panel to plummet uncontrollably due to insufficient damping, creating a severe pinch hazard. Or, a precision medical monitor’s screen slowly “drifts” out of position because it cannot hold its set angle, distracting medical staff during critical procedures.

These moments aren’t just poor user experiences—they are critical design flaws.

In B2B sectors, a product’s physical interaction experience directly reflects its engineering quality. A cover that feels loose, vibrates, or requires excessive (or insufficient) force to operate instantly signals “cheap” and “unreliable.” More critically, uncontrolled movement creates direct safety hazards and potential legal liabilities.

This article systematically analyzes critical equipment requiring torque hinges, providing an engineering decision framework and self-assessment checklist to evaluate whether your product design urgently needs this vital iterative upgrade.

What is a Torque Hinges?

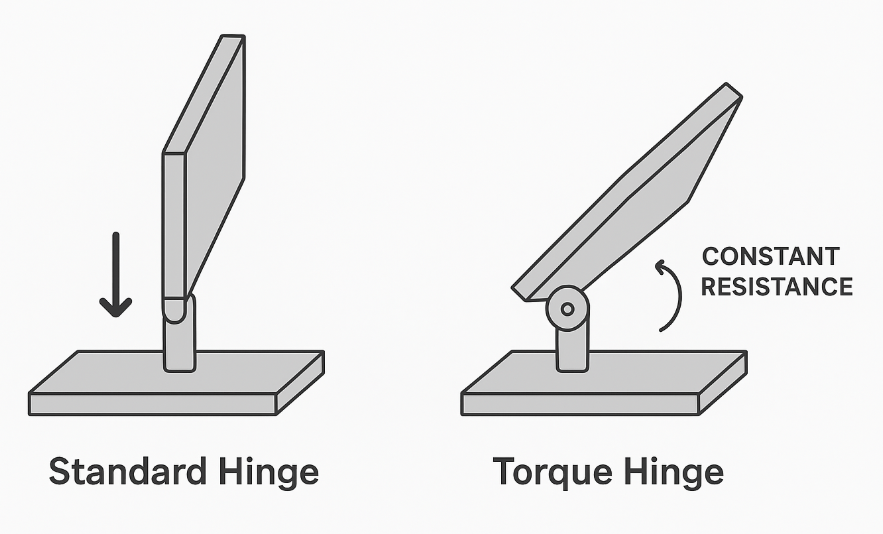

Standard hinges fall freely, while torque hinges can stop at any angle

Core Definition: Decoding “Torque” and “Damping”

From a physics perspective, torque (T) equals force (F) multiplied by lever arm (D)(NASA Glenn Research Center, n.d.). Standard hinges exhibit near-zero friction torque. Torque hinges, however, generate a constant or specific resistance (torque) through their internal precision damping mechanisms—such as spring clutches, friction pads, or viscous shear.

Key Functionality: Beyond “Pivoting”

The core value proposition of torque hinges lies not in “movement,” but in “control.”

- Position Holding: “Locks” a panel or screen at any angle within its range of motion, eliminating the need for secondary support structures like gas springs or struts.

- Smooth, Controlled Motion: Eliminates gravity-induced “free-fall” closures, delivering a steady, predictable damped motion sensation—the “soft-close” effect.

- Simplified Design: Enables designers to eliminate extra support components, thereby optimizing internal space, reducing assembly complexity, and minimizing failure points.

Key Terminology Distinction: Torque Hinge vs. Friction Hinge vs. Constant Torque Hinge

- Friction Hinge: A broad term encompassing all hinges that utilize friction to generate resistance.

- Torque Hinge: Typically denotes a friction hinge engineered to deliver a specific, repeatable torque value.

- Constant Torque Hinge: The highest tier. It maintains consistent torque throughout opening, closing, or any point in motion, providing the smoothest, most predictable tactile feedback.

Tactile Feedback and Perceived Quality

Recall the smooth, solid, precise tactile sensation when opening a high-end laptop. This engineered haptic feedback from torque hinges instantly translates into user confidence in product quality and precision manufacturing.

Which Devices “Must” Use Torque Hinges?

“Must” here is defined as: “Failure to use would result in severe safety risks, core functionality failure, or significant loss of product competitiveness.”

Safety First

Torque control is mandatory when safety and compliance are paramount.

Medical Devices

- Applications: Protective covers for heavy diagnostic equipment (CT/MRI), operating room monitor mounts, foldable bedside table panels.

- Reason: Must prevent accidental closure of heavy covers that could cause mechanical harm to operators or patients. Monitor viewing angle drift during critical operations is unacceptable.

Industrial Machinery

- Applications: Viewing windows on CNC machines, heavy-duty access doors on electrical control cabinets, safety guards on automated production lines.

- Reason: Maintenance personnel require hands-free operation. Relying on potentially failing gas springs or easily forgotten manual supports violates safety redundancy principles.

Aerospace & Defense

- Applications: Cockpit control panels, navigation device screens, overhead luggage compartments, tray tables in seats.

- Reason: All components must maintain their set positions under high vibration and acceleration. Any loosening may cause functional failure or safety incidents.

Functionality & Ergonomics

When “position retention” is the core product function itself.

Premium Electronics

- Applications: Laptops.

- Reason: This is the quintessential example. Torque hinges are the core components enabling the laptop form factor.

Point-of-Sale (POS) Terminals and Touchscreens

- Applications: Restaurant ordering kiosks, retail checkout counters, self-service terminals.

- Reason: Screens must adjust viewing angles to accommodate different users and eliminate glare. If the screen shifts under pressure during touch operation, it causes interruptions and reduces user satisfaction.

Adjustable Office Equipment

- Applications: Adjustable monitor stands, keyboard trays, multi-function desk lamps.

- Reason: The core selling points are “adjustability” and “position retention.” If the mount cannot hold at the set position, its core functional value is compromised.

Extreme and Dynamic Environments

When external conditions are demanding.

Marine and Recreational Vehicles (RV)

- Applications: Hatch covers, folding navigation consoles, storage compartment lids.

- Reason: Continuous vibration and dynamic loads (waves, road bumps) cause standard hinged covers to rattle, loosen, or shift unexpectedly.

Outdoor Equipment and Emergency Vehicles

- Applications: External storage boxes on ambulances/fire trucks, equipment racks in mobile command centers, military transport containers.

- Reason: Lids must remain open in high winds and withstand vehicle vibration. Operators (e.g., emergency responders) must maintain hands-free operation to focus on critical tasks.

Indirect Requirements from Industry Standards and Certifications

Industry standards rarely explicitly mandate “torque hinges must be used.” However, through stringent safety and stability requirements, they indirectly drive the need for controlled motion.

- Medical Equipment (IEC 60601-1): Clause 9 (Protection against mechanical hazards) mandates that equipment must not pose unacceptable risks to patients or operators during normal use or single-fault conditions. A display or cover unexpectedly closing due to gravity is clearly deemed an unacceptable mechanical hazard.

- Military and Aviation (MIL-STD-810H): Its Method 514 (Vibration) and Method 516 (Shock) tests are exceptionally rigorous. Under severe vibration, standard hinges may fail, while torque hinges must “lock” in position to ensure equipment functionality remains intact.

- Industrial Safety (OSHA 1910.212): The U.S. Occupational Safety and Health Administration (OSHA) mandates that machine guards protect operators from pinch points and falling objects. Heavy-duty guards relying on struts pose compliance risks; torque hinges provide built-in, automatic safety assurance.

Design Diagnosis: Does Your Product Need Upgrading?

Before-and-After Comparison: Gas Strut vs. Torque Hinge

This engineering checklist helps diagnose if your product design is “lagging.”

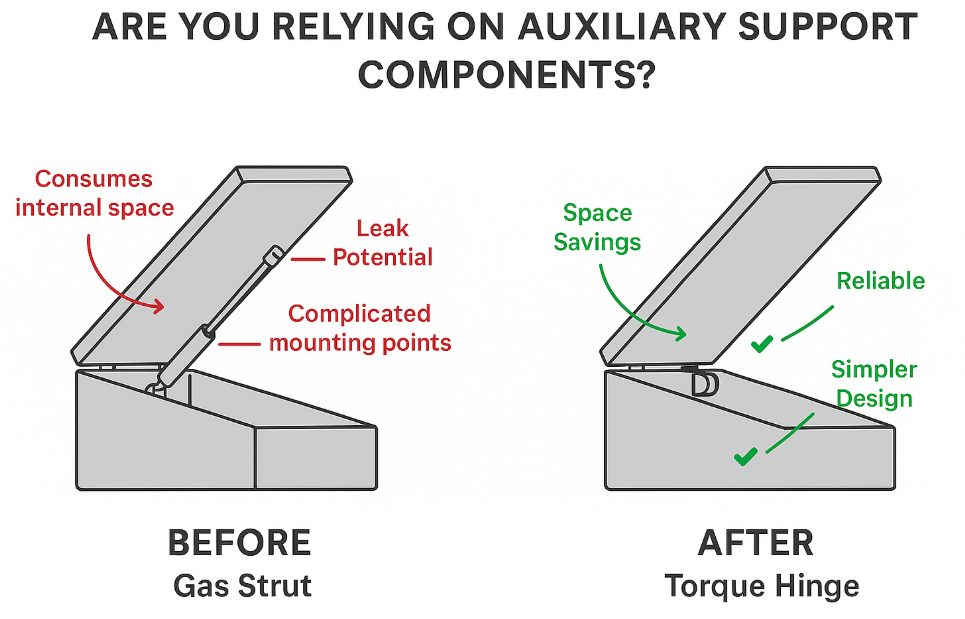

Are you relying on auxiliary support components?

Diagnostic Question: Does your product depend on gas springs, gas struts, or separate support rods to hold covers open?

Why this is an issue:

- Failure Point: Gas springs leak due to seal failure (especially in extreme temperatures), a common source of warranty claims.

- Design Space Invasion: They encroach on valuable internal device space, hindering internal layout.

- Assembly Complexity: They require precise mounting point calculations, increasing assembly time.

Reason for Upgrade: Torque hinges integrate pivot and support functions. They feature a simpler design with higher mechanical reliability and longer rated cycle life (typically tens of thousands of cycles), without invading internal space.

Does your product suffer from ergonomic flaws?

Diagnosing the issue: Do users require “two hands” to perform a task that should be accomplished with “one hand”? (e.g., holding the cover with one hand while operating internal components with the other)

Why this is problematic: This represents a classic ergonomic flaw. It increases operation time, reduces efficiency, and causes user frustration.

Reason for upgrade: Torque hinges optimize for one-handed operation. Users can lift the lid, which holds in any position, freeing hands to focus on core tasks.

Does your product present obvious mechanical hazards?

Diagnosing the issue: Does your lid or panel “free-fall”? Is there an obvious risk of pinching?

Why it’s a problem: This is the most severe issue. It not only leads to customer complaints but can trigger costly lawsuits and safety violations.

Reason for upgrade: Damped or constant-torque hinges completely eliminate free-fall. This isn’t just a functional upgrade—it’s a critical element of “active safety design.”

Does Your Product’s Tactile Experience Convey Negative Value?

Diagnostic Question: When users interact with your product, do they hear plastic scraping, metal clanking, or feel looseness and wobbling?

Why It Matters: Your product may use premium internal components, but if the user’s first physical touchpoint is a cheap hinge, the overall perceived value plummets.

Reason for Upgrade: Smooth, solid, controlled motion is the fastest way to signal “precision manufacturing” and “engineering quality.”

Return on Investment (ROI) Analysis for Upgrades

The initial purchase cost of torque hinges may exceed standard hinges, but evaluation must consider Total Cost of Ownership (TCO) and overall value.

| Cost Factors | Value Benefits |

|---|---|

| Initial hinge cost | Enhanced brand perception (enabling higher product premiums) |

| Potential design adjustment costs | Reduced warranty claims (eliminates gas spring failure issues) |

| Simplified installation (fewer parts and labor hours) | |

| Powerful market differentiation (“Hover at Any Position”) | |

| Enhanced Safety, Mitigating Compliance Risks & Liability Costs |

Technical Selection Guide: How to Properly Specify Torque Hinges

Assuming you decide to upgrade. Note: Choosing the wrong torque hinge (excessive or insufficient torque) is just as detrimental as not using one.

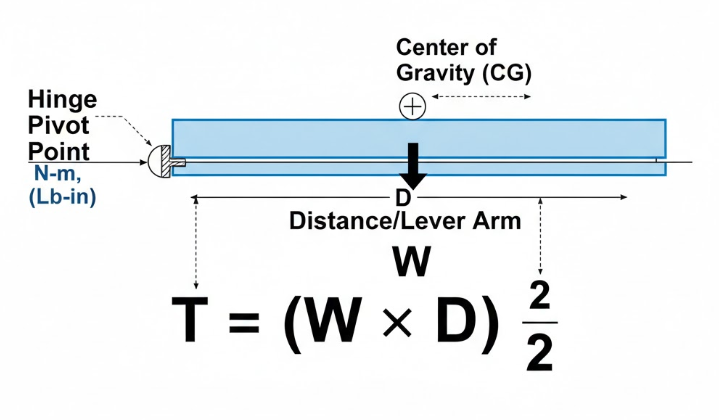

Step 1: Calculate Required Torque

Torque hinges calculation diagram

Why “guessing” won’t work: Torque is an engineering science requiring precise calculation to match loads.

Key formula (for horizontally mounted covers):

T = (W × D) / 2

- T = Total required torque (typically in N-m or Lb-in)

- W = Total cover weight

- D = Distance from pivot point (hinge) to cover plate’s center of gravity (*Note: “far end” in the original text is a simplified term; center of gravity is the more precise engineering term*)

Selection Note: Never omit additional components!

When calculating weight (W) and center of gravity (D), you must include: handles, locks, any installed wires, or additional components. These significantly impact final torque requirements.

Best Practice: Leverage Supplier Engineering Support

Professional hinge manufacturers offer complimentary engineering support. Provide your CAD models and load data for calculations or simulations—the optimal approach to ensure proper selection.

Select Damping Characteristics Based on Application

Constant Torque/Position Hold

- Features: Delivers consistent torque throughout the full range of motion.

- Applications: Laptops, medical monitors, POS terminals. Any application requiring “stop at any position.”

Adjustable Torque

- Features: A adjustment screw on the hinge allows fine-tuning of torque after installation.

- Applications: Prototyping, applications requiring field calibration, or allowing users to adjust tension based on varying loads.

Unidirectional Torque (Soft-Close)

- Features: Minimal resistance in one direction, strong resistance in the opposite direction.

- Applications: Soft-close functionality. Examples: Heavy-duty toolbox lids, toilet seats. Requires easy lifting but slow, controlled lowering.

Balanced/Gravity-Neutral Hinge

- Features: Advanced mechanism actively “neutralizes” gravity for near-zero-effort operation.

- Applications: Extremely heavy lids (e.g., large industrial ovens, semiconductor equipment shields).

Material Selection & Environmental Resistance

- Stainless Steel (e.g., 304, 316): Mandatory for food processing, medical, marine, or any highly corrosive, washdown environments.

- Zinc Alloy: Durable and easy to die-cast, standard for industrial enclosures and indoor equipment.

- Aluminum: When weight is paramount (e.g., aerospace, portable devices).

- Engineering Plastics: Cost-effective for lightweight applications with inherent corrosion resistance.

Mounting Methods and Cycle Life

- Mounting Method: Surface-mounted or concealed/recessed.

- Durability Validation:Verify the product’s life cycle rating. A hinge’s claimed torque value must remain within specifications after 25,000–50,000 cycles (e.g., torque decay < 20%).

- Validation should include:

- Cycle Test: Perform ≥25,000–50,000 open/close cycles to verify torque retention.

- Temperature Test: Conduct thermal stability testing from -20°C to +80°C.

- Vibration Test: Follow MIL-STD-810H, Method 514.8.

- Data Recording: Record torque decay curves to support long-term reliability assessment.

Application Case Study

Industrial Control Panels

Before Optimization: A manufacturer’s heavy-duty steel control cabinet door used gas springs. In cold factory environments, gas springs failed due to low temperatures, causing doors to unexpectedly close and damaging expensive internal HMI screens.

Solution: Gas springs were removed and replaced with a pair of high-torque stainless steel constant-torque hinges.

Result: Doors now remain open at any angle, unaffected by temperature. Internal space previously occupied by gas springs was freed up. Maintenance personnel safety significantly improved.

Mobile Medical Cart

Before Optimization: The monitor on the medical cart used a friction joint with a knob. Vibration during cart movement caused the screen to “nod” downward, requiring nurses to constantly retighten the knob—leading to inefficient operations and user complaints.

Solution: Replaced with a maintenance-free, preset-torque constant torque position control hinge.

Result: The screen now offers precise “set-and-forget” control and remains stable under high vibration. Nurse satisfaction has significantly improved, strengthening the equipment manufacturer’s brand reputation.

Premium Outdoor Grill

Before Optimization: A high-priced grill featured a heavy stainless steel lid that slammed shut with a loud “thud,” creating a tactile experience inconsistent with its premium positioning.

Solution: Integrated a balanced hinge mechanism.

Result: The 20-kilogram lid now lifts effortlessly with minimal force and closes with a smooth, controlled descent. This “premium” and “quality-driven” tactile experience perfectly aligns with its high-end market positioning.

Conclusion

Criteria for Assessing the “Necessity” of Torque Hinges

To recap, your product must use a torque hinge if it involves any of the following conditions:

- Safety – Risk of heavy objects falling or causing pinch injuries.

- Functionality – Requires maintaining position at a specific angle (e.g., screens, access panels).

- Ergonomics – Needs stable, hands-free operation for better usability.

- Environment – Operates under continuous vibration or dynamic loads.

The True Value of Upgrading: Beyond Cost

Upgrading to a torque hinge isn’t just about replacing a component—

it’s an investment in user experience, product safety, and brand value.

A well-engineered torque hinge transforms a “clunky” design into a “precision-controlled” product that delivers lasting performance and premium appeal.

It elevates not only tactile quality but also conveys the underlying engineering excellence that defines modern, safety-focused design.

Engineering Note:

While this article outlines the fundamental principles for torque hinge selection, engineers must perform actual load verification, environmental simulation, and fatigue testing before final design release.

Always confirm torque values under worst-case conditions to ensure reliability, safety, and compliance with relevant industry standards.