HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

The surface condition of an industrial stainless steel hinge influences corrosion resistance, cleaning and maintenance, friction and wear, and aesthetic consistency.

Mirror polishing does not fit every project.

Use corrosion class, hygiene level, visibility requirements, budget, and maintenance capability as the decision variables.

What is Mirror Polishing?

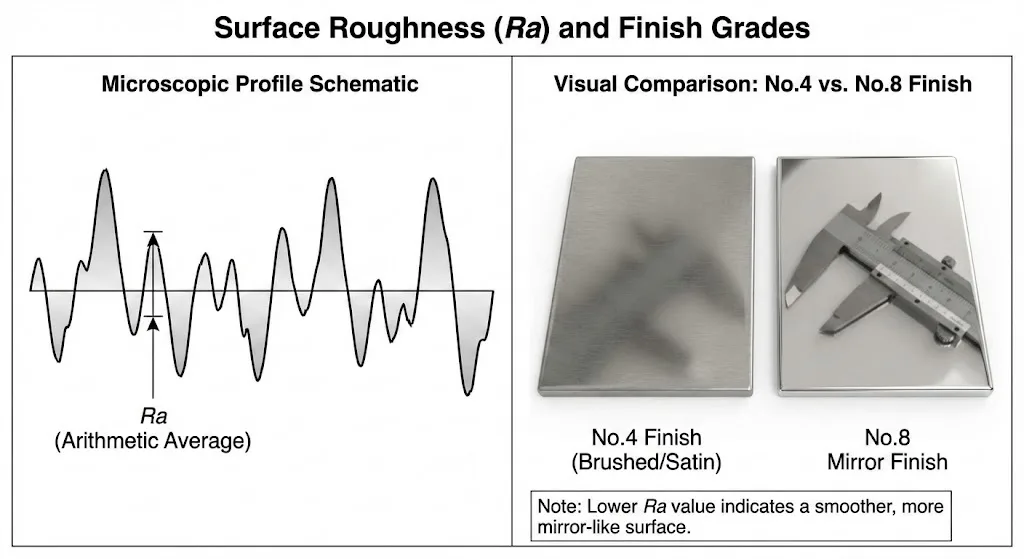

Mirror polishing typically corresponds to No.8 (8K) in stainless steel surface grade systems.

The process targets very low surface roughness, and engineers use Ra (Arithmetic Average Roughness) as the key metric.

Teams accept mirror finish based on measured Ra, not on visual “brightness.”

Mirror Polishing in the Standards System (Technical Backing)

ASTM / EN surface grade definitions

ASTM A480 describes stainless steel plate surface finish classifications, and it includes No.8 for mirror-finish use.

EN 10088-2 uses a similar symbolic system to define surface conditions and delivery requirements.

These standards turn “mirror finish” into an auditable requirement with clear definitions.

Hygienic roughness limits in global practice

Food and pharmaceutical equipment often includes explicit roughness limits in project specifications.

EHEDG hygienic design guidance emphasizes cleanability and low surface roughness.

Procurement documents often state the Ra maximum and require defined inspection methods.

Corrosive environment classification methods

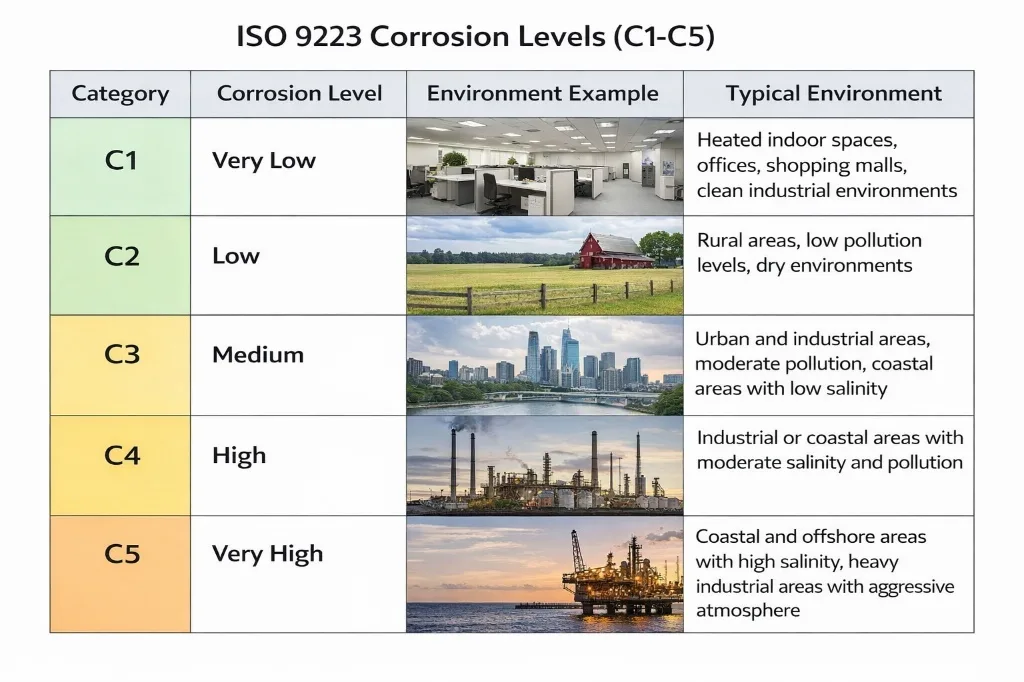

ISO 9223 defines atmospheric corrosivity categories such as C1 through C5.

It helps teams convert terms like indoor, coastal, or chemical zone into quantified corrosion risk.

As the corrosivity level rises, surface treatment becomes more important.

Core Effects of Mirror Polishing on 304 / 316 Hinges

Corrosion resistance: lower pitting triggers, same alloy limits

Mirror polishing reduces microscopic grooves and pits, lowering chloride retention and the chance of pitting initiation. However, surface treatment is a secondary defense. According to the SSINA (Specialty Steel Industry of North America), material chemistry remains the primary factor in high-chloride environments; choosing 316 stainless steel is the essential first step before applying a mirror finish to minimize pitting risk.

Cleaning and maintenance: smoother surfaces support predictable cleaning

Smoother surfaces reduce contaminant adhesion and simplify cleaning validation.

Food, pharmaceutical, and cleanroom projects often specify mirror polishing or electropolishing to reduce micropores and residues.

Project teams should place Ra targets and passivation requirements into procurement specifications when hygiene validation matters.

Friction and wear: polishing helps, but design dominates

Hinge wear depends on contact materials, load, lubrication strategy, and tolerances.

Mirror polishing can reduce peak friction on the surface.

Engineers still need correct pin materials, hardness targets, and lubricant compatibility to extend service life.

Aesthetic consistency: better visuals, higher upkeep

Mirror surfaces show scratches, fingerprints, and cleaning streaks more clearly.

High-touch or impact-prone scenarios increase cleaning and rework needs.

Non-visible hinges rarely justify the added aesthetic cost.

Why Many Industrial Projects Avoid Mirror Polishing

Cost: more steps, more time, more variability

Mirror polishing needs multiple grinding and buffing stages.

Complex hinge geometry makes corners, radii, and hole areas harder to finish consistently.

When performance gains remain unclear, the cost rarely supports the process.

Maintenance: mirror finishes need consistent cleaning and scratch control

Scratches raise local roughness and weaken both appearance consistency and corrosion stability.

Many factory environments do not support long-term mirror upkeep.

Without a defined maintenance protocol, mirror finish performance varies over time.

Glare and reflection: mirror surfaces create risk in some equipment

High-reflectivity surfaces can disrupt human visual comfort and sensor performance.

Operator cabs, optical systems, and surveillance equipment often avoid mirror finishes.

Projects in these categories usually specify low-reflection finishes while controlling roughness to maintain corrosion resistance.

Application Scenario Grading: When Mirror Finish Makes Sense

Class A: Food, pharma, cleanroom equipment (recommend)

Focus on hygienic design and roughness control.

Write Ra limits, inspection locations, passivation process, and acceptance records into the technical agreement.

Use EHEDG principles and align with internal cleaning validation workflows.

Class B: Marine and high salt-spray outdoor use (recommend 316 + high finish + passivation)

Start with ISO 9223 to define environmental corrosion grade.

In high-grade zones, 316 brings a clear material advantage, and high finish reduces pitting triggers.

Use salt spray verification standards, such as neutral salt spray systems, to confirm selection decisions.

Class C: Standard indoor cabinets and electrical enclosures (usually not needed)

Dry indoor environments often perform well with 304 brushed finish or 2B + passivation.

In accordance with standard industrial practice for Class C environments, mirror polishing is specified as an aesthetic upgrade rather than a functional longevity requirement.Budget-sensitive projects and hidden hinges typically favor brushed or passivated finishes.

Class D: Engineering machinery and heavy-duty outdoor use (not recommended)

These environments create impact risks, abrasive sand and mud exposure, and contaminant ingress.

Mirror surfaces show scratch damage quickly and drive higher maintenance workload.

Teams usually choose durable finishes and invest more effort in structural design and sealing.

Alternatives to Mirror Polishing

Brushed finish (commonly No.4 / #4)

This option suits most exposed parts on industrial equipment.

It controls visual consistency well and hides minor scratches better than a mirror finish.

It also costs less than mirror polishing while balancing appearance and maintenance.

Pickling + passivation (commonly aligned with ASTM A380 / ASTM A967)

This option suits welded and machined parts and projects that prioritize corrosion stability.

It removes contamination and free iron and helps restore a stable passive film.

It yields a matte appearance with lower decorative value but strong engineering robustness.

Vibratory finishing (deburring and uniform appearance)

This option supports high-volume small parts and focuses on deburring and edge safety.

It offers limited roughness improvement compared with mirror polishing.

Projects often combine it with passivation or additional polishing when they need lower Ra.

Sandblasting / bead blasting (low-reflection surface)

This option reduces reflections and creates a uniform matte look.

Blasting changes the surface state, so teams should add passivation to restore corrosion stability.

Highly corrosive environments require tight roughness control to avoid performance loss.

Engineering Decision Workflow (Actionable)

Step 1: Define the corrosion class using ISO 9223

Convert environment descriptions into a corrosion grade.

Higher grades require stronger control of both material selection and surface treatment.

High-grade zones often benefit from 316 plus a high-finish surface approach.

Step 2: Confirm hygiene and cleaning validation requirements

Food, pharmaceutical, and cleanroom projects need defined roughness targets and inspection methods.

Add Ra metrics and specify measurement locations.

Include cleaning validation requirements when the project requires formal verification.

Step 3: Identify visible and high-frequency contact hinges

Visible and high-touch hinges show fingerprints and scratches more easily.

A mirror finish demands a maintenance workflow that matches site conditions.

Hidden hinges rarely gain enough value from mirror finish.

Step 4: Treat polishing and passivation as one package

Mechanical polishing can introduce residue and contamination.

Use ASTM A967 or an equivalent method to define passivation requirements and inspection documentation.

If a supplier cannot control the process or provide reports, select a lower surface grade or a different solution.

Step 5: Validate with testing, not sample appearance

Testing provides stronger evidence than visual inspection.

Use salt spray or simulated-media comparisons and keep inspection records for critical parts.

Include surface roughness, cleanliness, and corrosion behavior in the evaluation.

Conclusion: Does the Hinge Need Mirror Polishing?

Mirror polishing fits high-corrosion and high-cleanliness environments and visible parts with strict aesthetic requirements.

Standard indoor industrial environments often meet life and cost targets with brushed finishes or passivation.

The decision depends on environmental grade, hygiene validation needs, maintenance capability, and total lifecycle cost.

FAQ

Q 1: Why do rust spots appear after mirror polishing?

Iron contamination or polishing residue often causes these spots.

Confirm that the supplier performed cleaning and passivation in line with ASTM A967.

High chloride exposure can still trigger pitting, especially on 304.

Q 2: How do I choose between mirror polishing and electropolishing?

Use mechanical mirror polishing for simple geometries with strong appearance needs.

Use electropolishing for complex shapes and internal surfaces such as pin holes.

Many projects use mechanical pre-polish plus electropolishing plus passivation for robust results.

Q 3: Do I need passivation after mirror polishing?

Yes. Passivation stabilizes the surface chemistry and improves corrosion consistency.

Skipping passivation increases the risk of flash rust, discoloration, and inconsistent performance.

Use ASTM A967 or ASTM A380 to define the process and documentation.

Q 4: What hygienic roughness should I specify, and how do I verify it?

Define a maximum Ra in the technical specification and list the measurement points.

Food and pharma projects often require measurable cleanability and verifiable surface quality.

Acceptance should include profilometer readings and cleaning validation records.

Q 5: Does mirror polishing shorten hinge life in abrasive environments?

Mirror polishing does not inherently shorten life.

Abrasive particles create scratches faster and increase local roughness, which can raise corrosion risk.

Heavy machinery and sandy environments usually benefit more from durable finishes and structural protection.

Q 6: How can I quantify whether mirror polishing is worth the investment?

Use a total lifecycle cost model rather than focusing only on unit price.

Include replacement frequency, downtime losses, labor hours for maintenance, and cleaning validation cost.

Mirror finish makes sense when it reduces long-term operational costs enough to offset upfront processing cost.