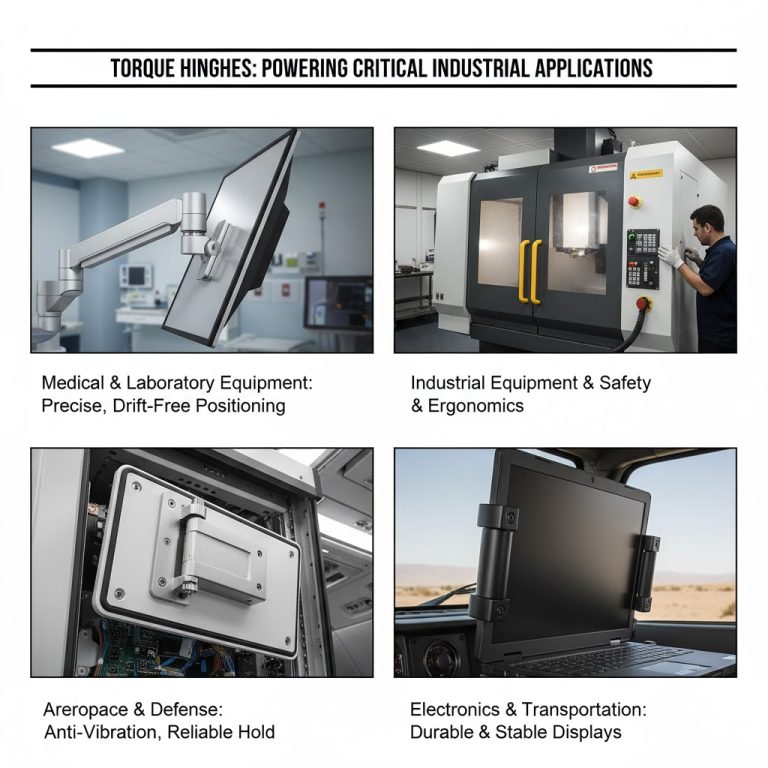

HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In industrial equipment, cabinets, and various types of specialized facilities, door locks play a critical role. They not only provide basic security protection, but are also key components that ensure the normal operation of equipment and meet specific environmental requirements. To choose the right door lock, you first need to understand the different types available.

Introduction to Types of Door Locks&Latches

Cam Latches

Operated by rotating a cam to engage a latch plate, this simple and reliable design is commonly used for cabinet doors.

Compression Latches

When locked, the latch compresses a sealing strip to provide excellent sealing performance, dustproof, and waterproof, suitable for outdoor or high-demand enclosures.

Rod Lock

Drives both top and bottom latches simultaneously via a hidden linkage, offering a concealed and secure design, commonly used for large doors or applications requiring multi-point locking.

Swing Handle Lock

Integrates the handle and lock cylinder, offering convenient rotation operation, safety, and reliability, commonly used for cabinet and toolbox door locking.

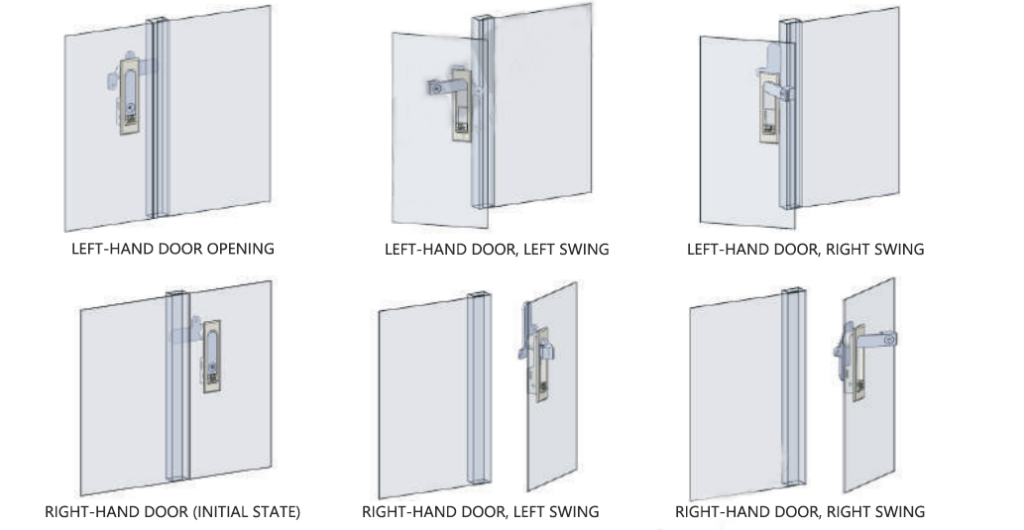

Left-Hand and Right-Hand Door Swing Explained

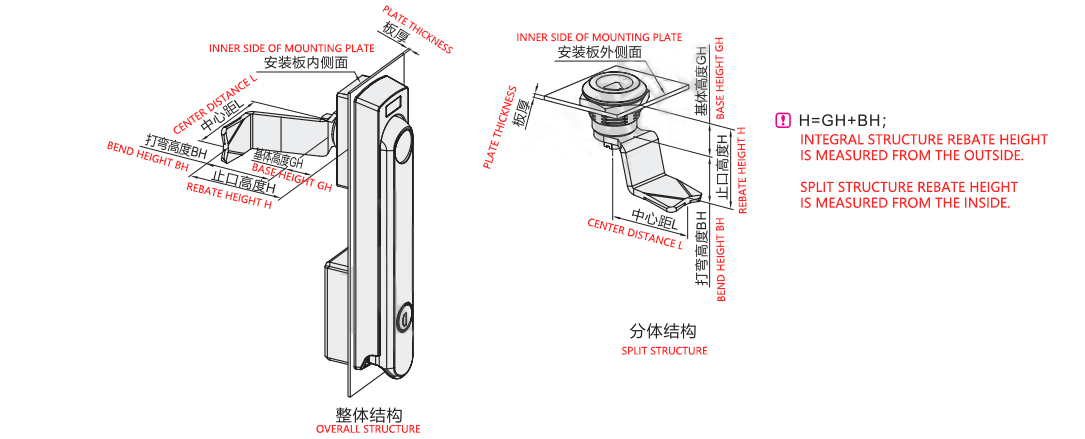

Understanding Recess Dimensions and Base Height in Panel Mounting

Mounting Techniques for Common Industrial Locks

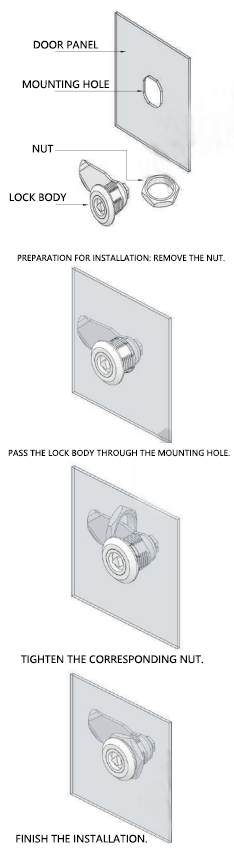

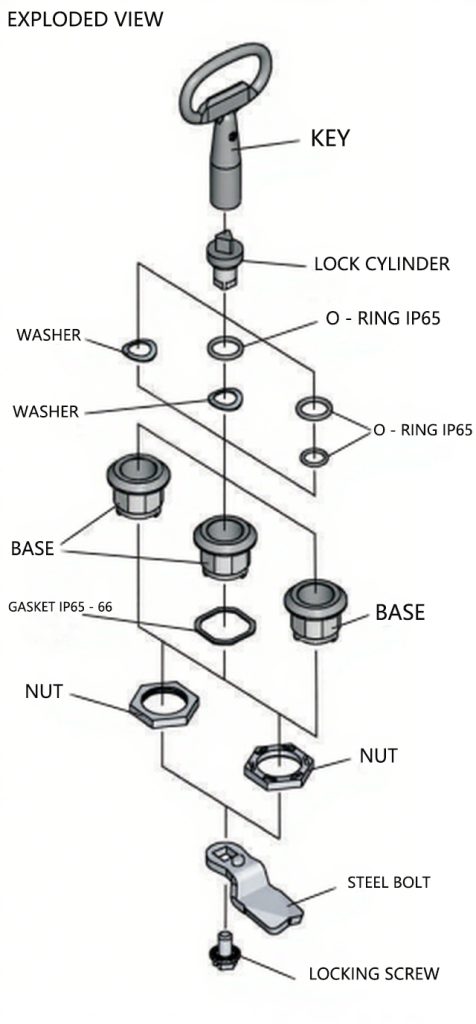

Cam Latch Installation Diagram

The figure below shows the installation and component breakdown diagram for Cam Latches. The left side shows the four-step installation process: “Remove the nut → Insert the lock body into the hole → Tighten the nut → Complete the installation.” The right side shows a clear breakdown of the components, including the key, lock cylinder, washer, O-ring, and base, as well as their assembly relationships, to help you understand the structural logic of the lock body.

Installation Diagrams

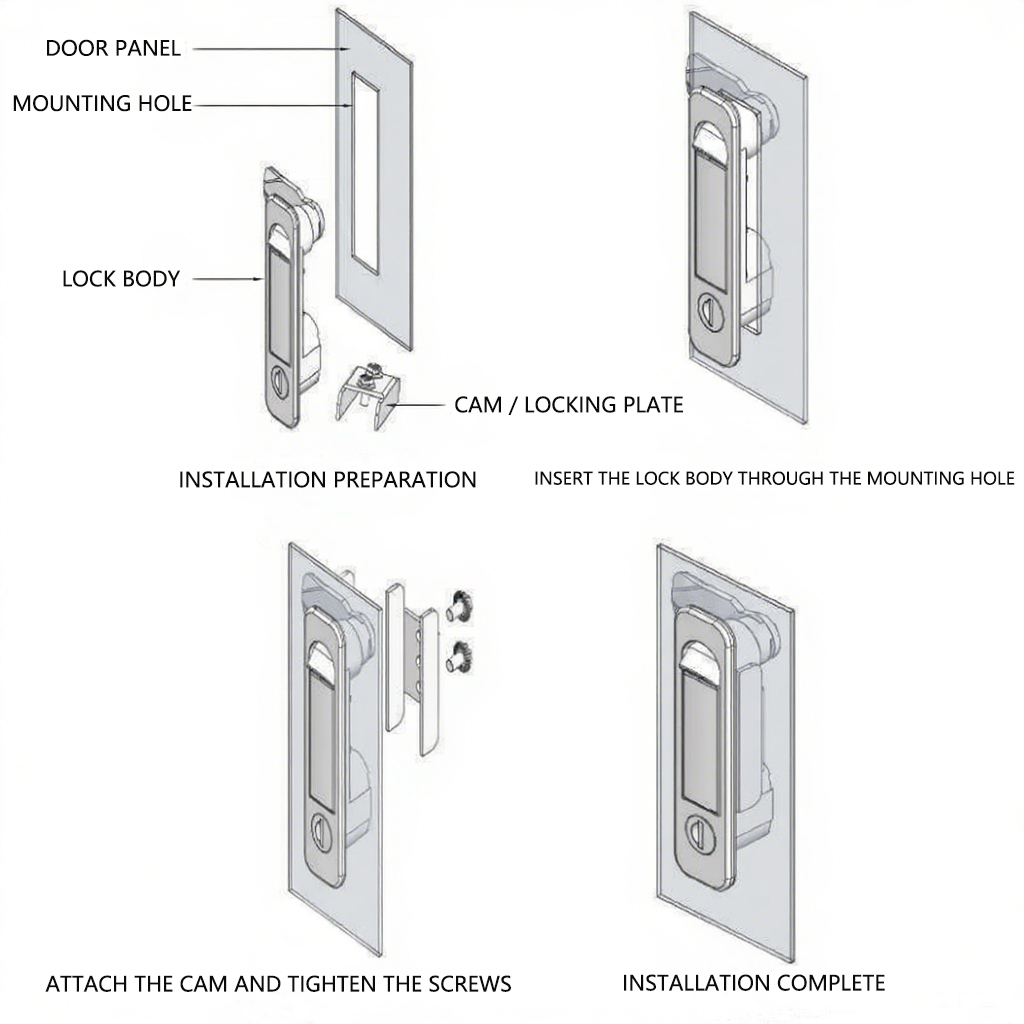

Swing Handle Lock Installation Diagram

Installation Diagrams

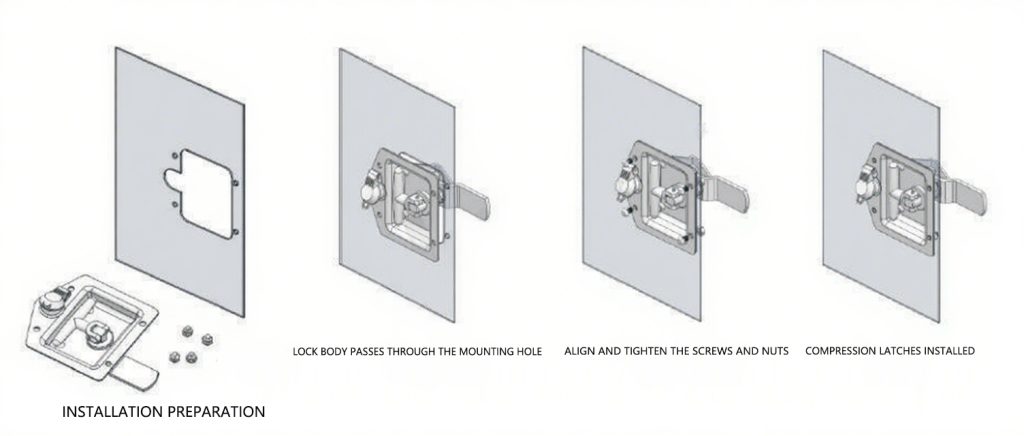

Compression Latches Installation Diagram

Installation Diagrams

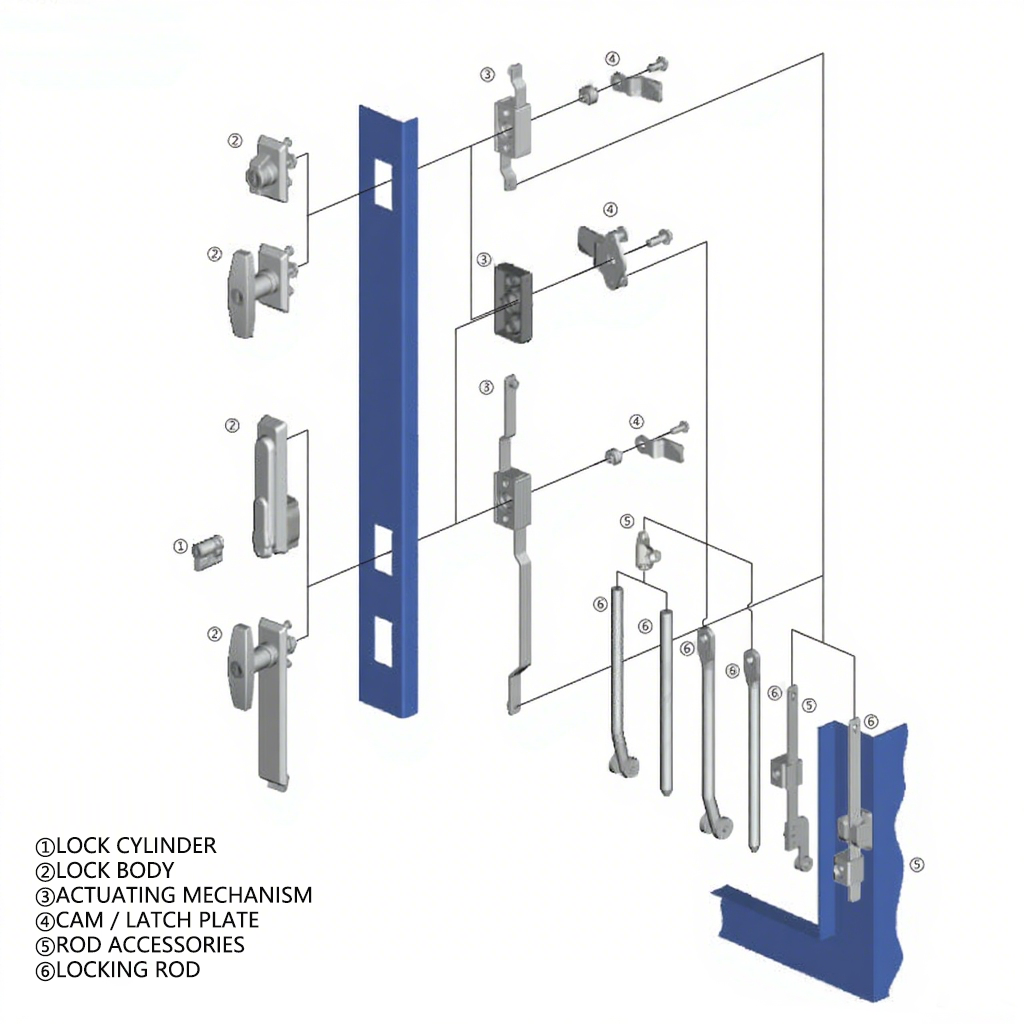

Rod Lock Installation Diagram

Installation Diagrams

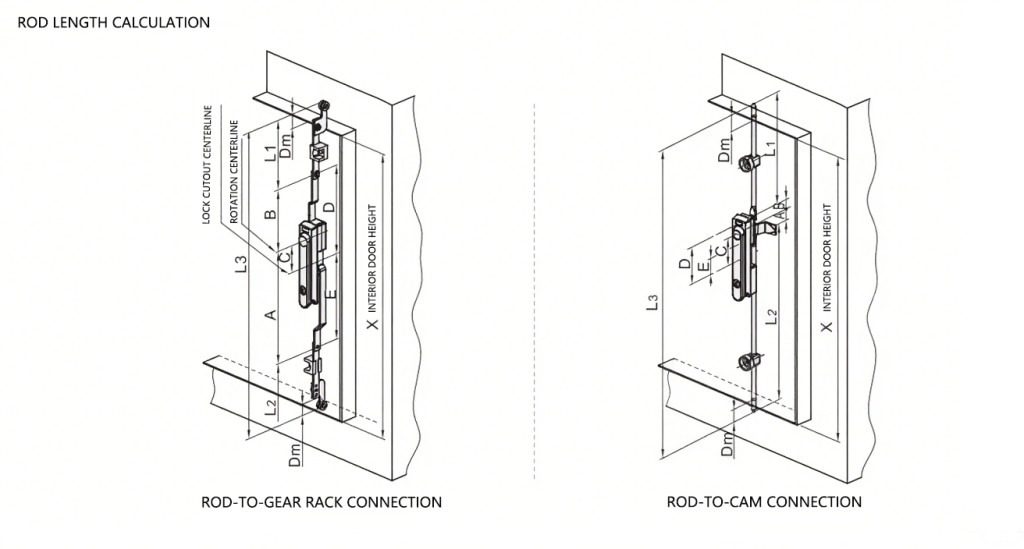

Rod Length Calculation

The rod length calculation is based on the distance between the lock cutout centerline, the rotation centerline, and the interior door height. Ensure proper alignment at both the rod-to-gear rack connection and the rod-to-cam connection to achieve smooth locking operation.

Calculate the Rod Length Based on the Interior Door Height

To determine the correct rod length, use the following formulas based on the alignment of the door panel:

1. When the door panel center aligns with the lock rotation centerline:

- L1 = (X / 2) – B + (Dm – 2)

- L2 = (X / 2) – A + (Dm – 2)

2. When the door panel center aligns with the lock cutout centerline:

- L1 = (X / 2) – D + (Dm – 2)

- L2 = (X / 2) – (A – C) + (Dm – 2)

Parameters

- X – Door frame opening height

- Dm – Transmission extension travel

- A, B, C, D – Structural dimensions based on lock and panel design

Application Notes

- These formulas are suitable for calculating the length of the connecting rod installed inside the sealing strip.

- The results are for reference only. Always consider the actual mounting and structural conditions before finalizing rod length.

- For rods installed outside the sealing strip, determine the length based on specific cabinet design requirements.

- In all cases, the final rod length L3 should be less than the internal height of the cabinet frame to ensure proper fit and operation.

Conclusion

For accurate and reliable installation, always refer to manufacturer specifications, and consider environmental factors like sealing requirements and space constraints. Use the rod length calculation as a reference, and adjust according to your specific cabinet design.