HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Rack and cabinet end equipment handles are key elements in the realm of data facilities and data server facilities, providing both utilitarianism and style to the structure. These handles are designed to make the procedure for accessing and managing devices inside racks and cabinets more efficient and easy to use. With the continuous expansion of technological advancements and the rising requirements for data retention and computation, the significance of premium handles cannot be emphasized enough. In this article, we will explore the different aspects of rack and cabinet end equipment handles, including their Shape, utility, and the needs related to them.

Introduction of Aluminum Handle

1. Robustness and Rigidity

The main criterion for rack and cabinet end equipment handles is Robustness and Rigidity. These handles must be able to endure the challenges of regular use, including significant lifting and possible collision from outside influences. The materials used for handles, such as steel or reinforced plastic, must be selected carefully to ensure they can bear the weight of the equipment they are designed to uphold.

2. Safety and Human Factors

.png)

Safety and Human Factors are key considerations when designing handles for hardware enclosures. The handles should be designed to minimize the chance of harm and provide a ergonomic hold for users. This includes features such as antiskid surfaces, suitable bar lengths, and a shape that allows for simple grasping and lifting.

3. Accessibility and Ease of Use

Accessibility and Ease of Use are essential for streamlined operation of hardware in enclosures. Handles should be designed to allow users to easily reach and access the equipment they need without exertion or inflicting harm to the equipment or the surrounding environment.

4. Interoperability and Tailoring

The ability to customize handles to fit specific requirements is important for a vast array of uses. Compatibility with different sorts of racks, cabinets, and equipment is crucial to ensure that the handles can be used in different environments. This includes considerations such as bar length, installation choices, and compatibility with multiple locking systems.

In the following sections, we will investigate more thoroughly into each of these requirements and talk about the significance of taking them into account when choosing or creating racking and cabinetry end equipment knobs. By comprehending the diverse demands and their consequences, we can guarantee that the knobs we select or make are both operable and efficient for their intended use.

Common Types of Industrial Handles (By Shape)

Industrial handles come in various shapes to suit different applications:

Round Handles

Perfect for round equipment, providing an even grip.

Square Handles

Strong structure, commonly used for heavy machinery.

Tube Handles

Tube-shaped design, often seen on industrial boxes.

U-Shaped Handles

Two-point design, easy to pull, widely used on cabinet doors.

T-Shaped Handles

T-shape offers a strong grip, ideal for tasks requiring extra force.

Arch Handles

Curved design adds style, popular in modern industrial equipment.

Crank Handles

Designed with a crank for rotating tasks.

Recessed Handles

Flush with the surface, keeping things flat. Great for sliding doors or cabinets.

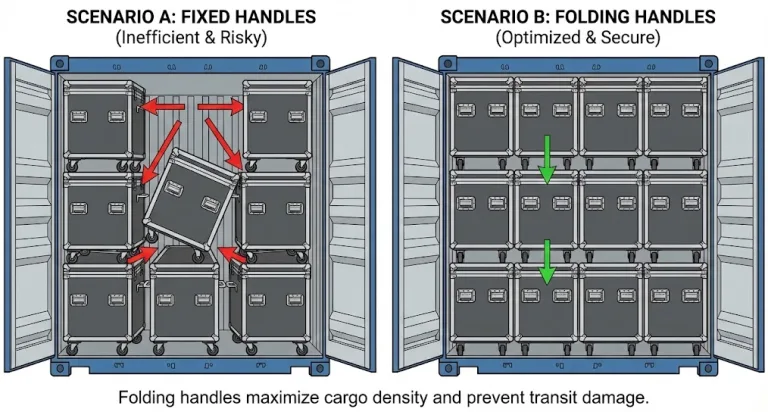

Hidden Handles

Foldable or hidden to save space. Often seen in high-end devices.

Where to Use Industrial Handles

Different industrial handles are used in various scenarios:

U-Shaped Handles

Made of stainless steel or aluminum. Mounted on surfaces like industrial cabinets or storage boxes. Designed for comfort (ergonomic).

Recessed Handles

Made of plastic or metal. Installed flush into surfaces like sliding doors. Keeps surfaces smooth.

T-Shaped Handles

Aluminum material. Front-mounted on heavy machines or industrial doors. Handles heavy loads.

Lockable Handles

Zinc alloy material. Surface-mounted on server racks. Improves security.

Choosing Materials for Industrial Handles

Selecting the right material for your industrial handles:

Aluminum

Lightweight, suitable for portable devices.

Stainless Steel

Resistant to rust, ideal for wet environments such as hospitals or kitchens.

Plastic

Light, inexpensive, and sufficient for basic needs.

Installing Industrial Handles

Industrial handles can be installed in several ways:

Surface Mounting

Attached directly to the surface. Easy to install, suitable for general use.

Recessed Mounting

Fits into the surface, keeping it flat. Common in modern designs.

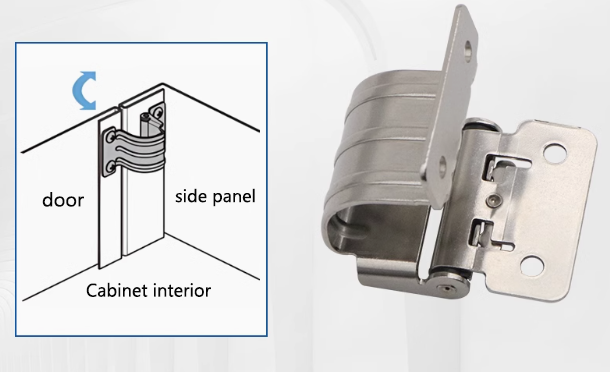

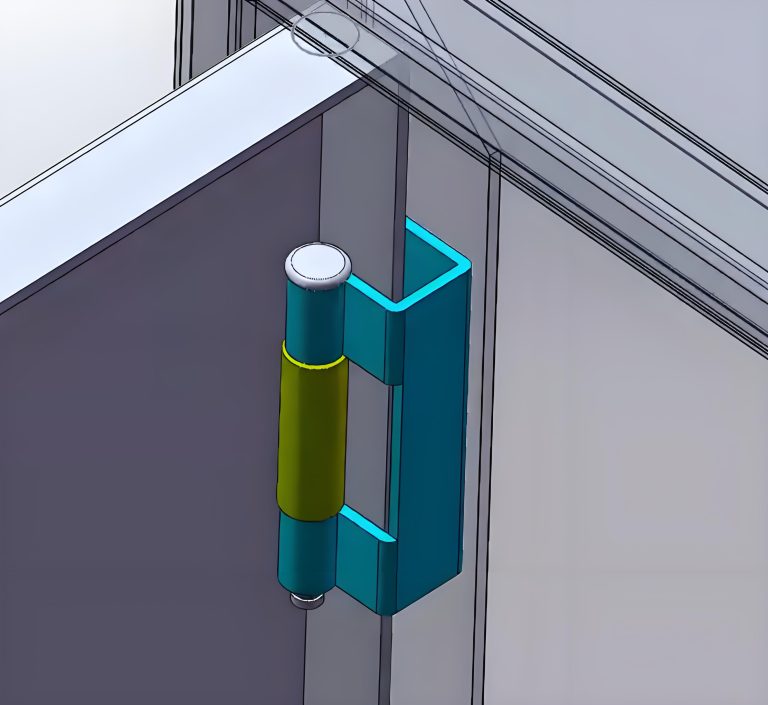

Hidden Mounting

Foldable or hidden to save space. Ideal for tight areas.

Front Mounting

Installed from the front, easy to use. Often seen on cabinet doors.

Rear Mounting

Fixed from the back, no visible screws. Looks clean and stylish.

Why Industrial Handles Matter

Whether you need a heavy-duty T-shaped handle for machinery or a sleek hidden handle for cabinets, industrial handles are crucial for safety and functionality. Always match the handle type, material, and installation method to your specific needs. From stainless steel U-shaped handles in kitchens to recessed aluminum handles in modern factories, these small components make a significant difference!

If you are looking for high-quality handles, we recommend that you contact HTAN specialized suppliers for more product information and technical support.