HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In industrial supply chain management, component physical geometry has a decisive impact on the final Landed Cost. For portable equipment, server chassis, or precision instrument cases involved in bulk shipping, protruding fixed hardware often leads to a non-linear increase in packaging volume. This significantly drives up storage density costs and international freight fees based on Volumetric Weight.

Although the initial unit price of folding handles is typically higher than traditional fixed pulls, their ability to eliminate ineffective protrusions on equipment surfaces substantially optimizes logistics stacking efficiency. In a Total Cost of Ownership (TCO) model, these spatial savings often offset and exceed the hardware price difference. Furthermore, flush-mounted designs compliant with ISO and EN safety standards effectively reduce collision damage risks during transit and associated claim costs.

This article analyzes why folding handles offer a superior balance between upfront investment and long-term operational benefits from a procurement and supply chain optimization perspective, providing selection criteria based on international standards.

Maximizing Spatial Efficiency and Stackability

For logistics managers and equipment engineers, space equals cost. Evaluations of product lifecycles reveal that the impact of hardware geometry on logistics costs is frequently underestimated.

The Concrete Impact on External Dimensions

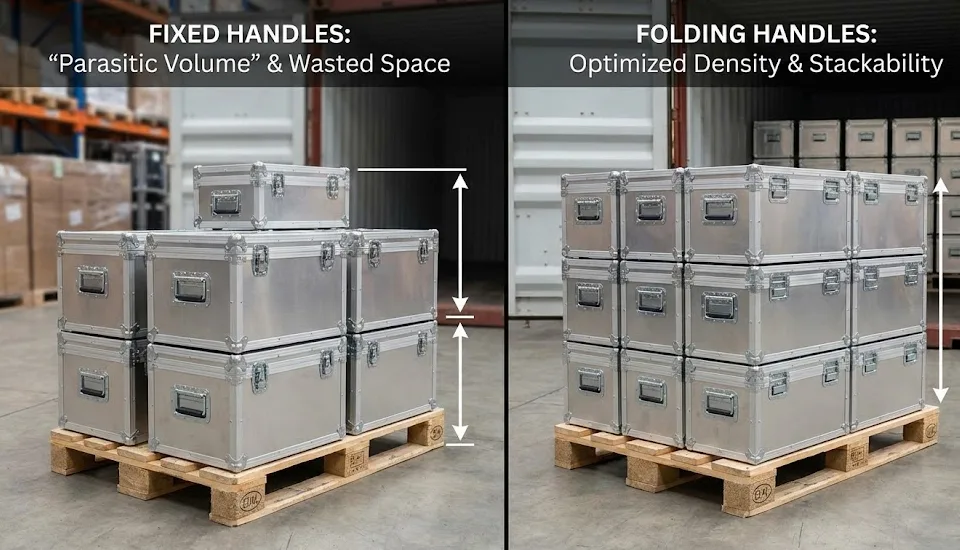

Fixed handles act as “parasitic volume” on equipment enclosures. Consider the following data points:

If you design a standard aluminum transport case measuring 600mm x 400mm x 400mm and install fixed handles with a 50mm depth on both sides:

- Single Unit Impact: While the handle occupies only a localized space, calculating for container loading or rack storage requires using the “effective envelope dimensions.”

- Volume Calculation: The length including handles increases from 600mm to 700mm. This results in an approximate 16% increase in the effective volume occupied by each case.

Logistics Case Study:

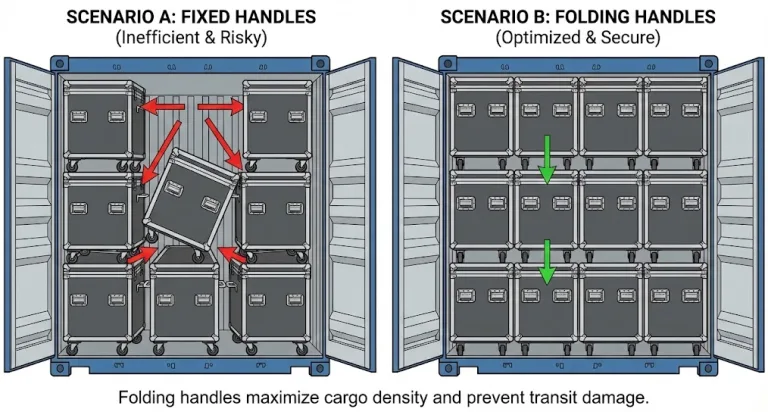

In a recent project involving the export of precision instruments to Europe, client analysis showed that protruding fixed handles limited palletization on standard Euro Pallets (1200mm x 800mm) to only 2 cases per layer.

- Optimization: The design was updated to specify Recessed Folding Handles.

- Result: The case surface became flush, allowing 3 cases per layer. By changing only the hardware, single-pallet transport efficiency increased by 50%. This demonstrates the significant contribution of eliminating protrusions to logistics cost reduction.

Improving Equipment Stackability

Beyond individual unit volume, inter-equipment compatibility is critical. Folding handles allow case sides to sit flush against other planes.

- Warehouse Storage: In automated storage and retrieval systems (AS/RS), robotic arms have strict requirements for outer dimensions. Folding handles ensure side clearance, preventing mechanical jamming on conveyors or storage bays.

- Rack Mounting Standards: For IT and telecommunications equipment, adherence to the EIA-310-E standard (19-inch rack standard) is mandatory.

- Recommendation: Folding handles are essential for server chassis or rack-mounted test equipment.

- Rationale: Any protruding fixed hardware may prevent the equipment from sliding into standard cabinets or obstruct airflow channels for adjacent devices.

Enhancing User Safety and Ergonomics

Safety is not an option; it is a mandatory engineering requirement. In industrial environments, protruding hardware represents a potential risk source.

Eliminating Snag Hazards

In Occupational Health and Safety (OHS) assessments, “Catch Points” are a critical inspection item.

- Definition: Scenarios where loose clothing, tool belts, or cabling get caught on protruding handles while technicians move through narrow corridors or complex machinery setups.

- Consequence: Risks range from equipment damage due to falls to personnel injury.

- Standard Reference: OSHA 1910.22 (Walking-Working Surfaces) indirectly mandates that passageways must remain unobstructed.

- Recommendation: Use spring-loaded folding handles in high-traffic areas or on portable field equipment. When released, the handle automatically retracts to the case body, eliminating the snag hazard.

Ergonomic Grip and Load Distribution

Handles are not just for lifting; they must protect the operator’s musculoskeletal system.

- Grip Diameter: Many low-cost fixed handles use thin 6mm–8mm wire grips. ISO 9241-5 warns that high localized contact pressure on the hand increases the risk of discomfort and soft-tissue strain. Thin handles create pressure points, especially when lifting loads over 10 kg.

- The Folding Advantage: High-quality folding handles typically feature tubular grips with diameters of 16mm to 25mm, or utilize molded rubber sleeves.

- Contact Area: Increased diameter expands the contact surface between the palm and the handle, reducing pressure per square inch.

- Slip Resistance: Environmental testing indicates metal surfaces are difficult to grip in low temperatures. Folding handles with rubber or dip-coated grips provide necessary thermal insulation and friction, preventing slippage when transporting high-value equipment.

Structural Integrity and Load Capabilities

A common misconception is that “folding” implies “fragile.” Properly engineered folding handles are designed to meet rigorous heavy-duty applications.

Mechanical Design of Folding Mechanisms

A superior folding handle consists of two core mechanical components:

- Return Spring:

- Crucial for maintaining the handle in a flat position when not in use.

- Technical Spec: Specify 304 Stainless Steel torsion springs rather than standard carbon steel. Carbon steel springs are prone to rust and fatigue fracture over long-term use, leading to “limp” handles and noise generation.

- 90-Degree Stop:

- The handle must stop firmly at 90 degrees when lifted.

- Design Advice: Inspect the limit block design. Premium handles feature thickened metal bosses at the limit point. Weak limit structures can cause the handle to over-rotate during heavy lifting, creating a Pinch Point that risks finger injury.

- Vibration Damping: High-end models integrate rubber bumpers in the folded position. This is critical for equipment requiring MIL-STD-810G (Vibration Testing) compliance, preventing metal-on-metal impact noise during transport.

Load Rating Classification and Safety Factor

Selection must go beyond “Rated Load.” Understanding the Safety Factor is essential.

- Light Duty: Typically rated 200N – 400N. Suitable for electronic instrument cases.

- Heavy Duty: Rated 1000N – 2500N. Suitable for military shelters or heavy generator sets.

- Safety Factor Calculation:

- Example: Case total weight is 50kg (approx. 500N).

- Do not select a handle rated exactly at 500N.

- Industry Best Practice: Apply a Safety Factor of at least 2.0 or 3.0. For a 500N case, specify handles rated for at least 1000N – 1500N.

- Rationale: Dynamic loads generated during transport (e.g., stair climbing, truck unloading) create instantaneous peak forces far exceeding static weight.

Material Selection for Harsh Environments

Environmental factors are the primary cause of hardware failure. Recommended material schemes based on application scenarios include:

Stainless Steel (Grades 304 & 316)

- 304 Stainless Steel: The industrial standard configuration. Offers good corrosion resistance for most outdoor equipment and humid environments.

- 316 Stainless Steel: Mandatory for marine environments (shipboard equipment), chemical plants, or food processing facilities.

- Data Point: In ASTM B117 salt spray testing, 304 stainless steel may show surface rust after 500 hours, whereas 316 stainless steel retains its finish beyond 1000 hours due to the addition of Molybdenum.

Aluminum and Zinc Alloys

- Application: Avionics cases, photography equipment.

- Advantage: Extremely lightweight, contributing to overall equipment weight reduction.

- Surface Treatment: Aluminum can be anodized per MIL-A-8625. This provides electrical insulation and allows for color customization (black, silver) to match industrial design aesthetics.

Chrome Plated Steel

- Application: General-purpose toolboxes, indoor warehouse equipment.

- Advisory: While cost-effective, if the plating is breached, the underlying steel will rust rapidly. Not recommended for projects with long-term outdoor exposure.

Types of Folding Handles and Specific Applications

Folding handles are categorized into three main types based on installation and function:

Surface Mounted Folding Handles

- Description: The entire mechanism is installed directly onto the panel surface.

- Use Case: The best choice for Retrofitting. For example, upgrading legacy wooden shipping crates often involves securing surface-mounted handles with self-tapping screws, eliminating the need for complex cutting.

- Limitation: While the bail folds, the mounting base still retains a thickness of approximately 10mm-15mm.

Recessed (Tray) Folding Handles

- Description: The mechanism is mounted within a recessed metal dish (tray).

- Advantage: The only solution for “Zero Protrusion.” The handle retracts completely into the recess, sitting flush with the case surface.

- Standard Application: The standard configuration for Flight Cases certified under ATA 300 (Air Transport Association). In air cargo, protrusions can damage baggage handling systems or other cargo.

Spring-Loaded vs. Free-Fall

- Spring-Loaded: Internal high-tension springs return the handle immediately upon release.

- Advisory: Mandatory for vehicle-mounted equipment (e.g., fire trucks, ambulances). Free-fall handles will flap against the case due to road vibration, causing unacceptable noise levels.

- Free-Fall: Relies on gravity to hang down.

- Advisory: Suitable only for static storage cases. Simple structure and low failure rate, but lacks vibration dampening.

Installation and Engineering Considerations

Even the highest quality handle will fail if installed incorrectly. Implementation guidelines for structural engineers follow:

Installation Methods

- Through-Hole Mounting:

- The strongest installation method. Uses bolts passing through the panel, secured with nuts on the reverse side.

- Locking Requirement: As handles withstand dynamic tension, Nyloc Nuts or thread lockers (e.g., Loctite) are recommended to prevent loosening.

- Weld-On Mounting:

- Suitable for permanent heavy-duty steel enclosures. Post-weld rust prevention treatment is required.

Panel Thickness and Reinforcement

A common failure mode observed is panel deformation despite the handle remaining intact.

- Stress Concentration: Lifting a 50kg case concentrates force around screw holes.

- Solution: For thin-walled chassis (e.g., 1.0mm – 1.5mm sheet metal), a Backing Plate or large-diameter washer must be installed on the interior.

- Function: The backing plate converts Point Load into Surface Load, distributing stress over a larger area to prevent sheet metal tearing.

Comparative Analysis: Folding vs. Fixed Handles

To assist in the final decision-making process, a structured comparison of the two options follows:

| Feature Dimension | Folding Handle | Fixed (Pull) Handle |

| Space Footprint | Minimal (Can be flush mounted) | High (Permanent 30-60mm protrusion) |

| Stackability | Excellent (Allows tight packing) | Poor (Requires gap buffers) |

| Safety (OHS) | High (No snag hazards) | Medium/Low (Collision risk) |

| Aesthetics | Professional/High-Tech | Utilitarian/Industrial |

| Maintenance | Low (Occasional spring check) | Zero (No moving parts) |

| Initial Cost | Medium | Low |

| Long-haul Logistics | Low (Reduced volumetric weight) | High (Higher billable volume) |

Conclusion

While the initial procurement cost of folding handles is marginally higher than fixed handles, the long-term value delivered is substantial. For professional equipment requiring frequent movement, shipping, or operation in confined spaces, folding handles provide:

- Extreme Spatial Efficiency: Lowering logistics and warehousing costs.

- OSHA Compliance: Reducing workplace snag hazards.

- Ergonomic Operation: Protecting operator health.

Industry analysis suggests that for equipment designed for portability, transport, or field operation, investment in high-quality folding handles is a critical detail that distinguishes professional industrial products from amateur DIY projects.

FAQ

Q1: What material should I choose for folding handles exposed to outdoor environments?

It is strongly recommended to use 304 or 316 Grade Stainless Steel. While chrome-plated steel is cheaper, the plating peels easily under UV and moisture exposure, leading to rust. For marine or coastal environments, 316 Stainless Steel is the only reliable choice due to its Molybdenum content, which effectively resists chloride corrosion.

Q2: What is the required cutout size for recessed folding handles?

This depends entirely on the specific model. Every recessed handle has a specific “Cutout Template.” Before commencing sheet metal fabrication, always request the CAD file from the supplier. Do not attempt to manually measure the physical part for cutting, as industrial manufacturing tolerances are strict; minor errors can result in loose fits or installation failure.

Q3: What is the “90-Degree Stop” feature and why is it important?

A 90-degree stop means the handle rotates only to a position perpendicular to the panel (90 degrees) when lifted and does not flip back beyond this angle. This is critical for safety: if a handle can rotate 180 degrees, the user’s knuckles risk being trapped between the handle and the case surface (creating a Pinch Point) during lifting. The 90-degree stop protects the user’s hands and provides a stable lifting angle.