HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In industrial equipment, heavy-duty hinges, although seemingly insignificant, are key components that affect the performance of the equipment.

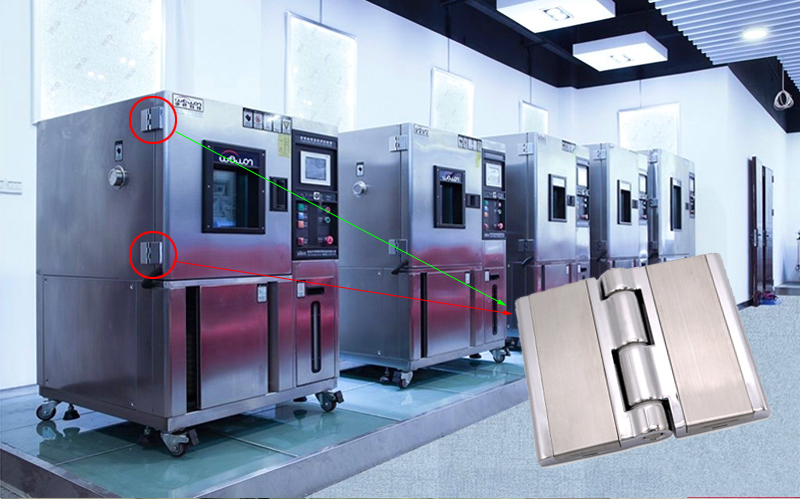

Especially in the temperature humidity test box such as precision equipment, hinge selection is directly related to the box sealing, durability and long-term stability.

If the hinge can not withstand the extreme temperature and humidity environment, may lead to sealing failure, and even affect the accuracy of the experimental results.

Therefore, the selection of suitable temperature humidity test box heavy duty hinges is not only a technical problem, but also the basis for reliable operation of the equipment.

In this paper, we will analyze the application of heavy-duty hinges in Temperature Humidity Test Box, including selection criteria, installation techniques, maintenance methods, etc., to help users make more scientific decisions.

understand the use of temperature humidity test box demand

temperature humidity test box main functions and application scenarios

temperature humidity test box through accurate control of temperature and humidity, simulating specific environmental conditions, widely used in the following scenarios:

- Laboratory environment simulation: for example, testing the performance changes of materials in high temperature and high humidity or low temperature and dry environment.

- Aging test of electronic components: to verify the stability of products under long-term extreme conditions.

- Material reliability testing: e.g. weathering analysis of plastic, metal and other materials.

In these scenarios, the box door needs to be opened and closed frequently and must remain sealed for a long time.

Therefore, laboratory temperature humidity test box applications place higher demands on the durability and environmental resistance of hinges.

Special requirements for hinges

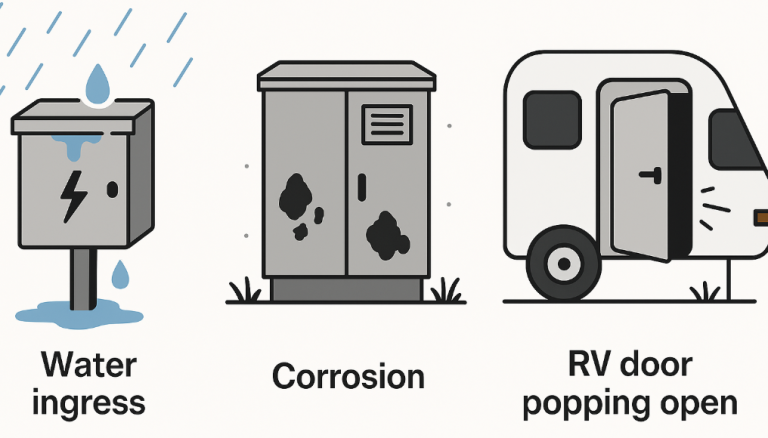

- Corrosion resistance: temperature humidity test box may come into contact with chemical gases or condensation, hinges need to be able to resist corrosion.

- High temperature resistance, low temperature resistance: the working temperature range is usually -70 ℃ to 150 ℃, hinge materials need to adapt to the extreme temperature difference.

- Resistance to humidity and mildew: under long-term high humidity environment, ordinary hinges are easy to rust or breed mildew, so it is necessary to choose high temperature and humidity resistant hinges.

Key features of heavy duty hinges

Load-bearing capacity

The static load (static load) and dynamic load (dynamic pressure when opening and closing the door) of high load bearing heavy duty hinges are the core indexes for selection.

Material and surface treatment

- Stainless steel: 304 or 316 stainless steel is the first choice, strong corrosion resistance, suitable for high humidity environment.

- Galvanized steel: lower cost, but long-term rust resistance is weak, need to match the surface coating process.

- Aluminum alloy: lightweight design, but lower strength, suitable for small equipment.

The life span of anti-corrosion heavy duty hinge material can be further enhanced by electroplating and powder coating process.

Sealing and waterproof design

Silicone gaskets or moisture-proof adhesive strips should be used at the connection between the hinge and the box to prevent moisture from seeping in.

Some high-end models will be designed with drainage slots to avoid water corrosion.

Waterproof heavy-duty hinges can effectively extend the service life of the equipment in humid environments.

Durability and Longevity

Industry standards require durable heavy duty hinges to last at least 100,000 opening and closing cycles.

Hinges with ball bearings or self-lubricating design can reduce wear and tear, while inferior hinges may loosen or jam after thousands of uses.

the common heavy duty hinge type and brand recommendation

All stainless steel hinges

Stainless steel thermostat hinges are corrosion-resistant, suitable for laboratory or coastal areas.

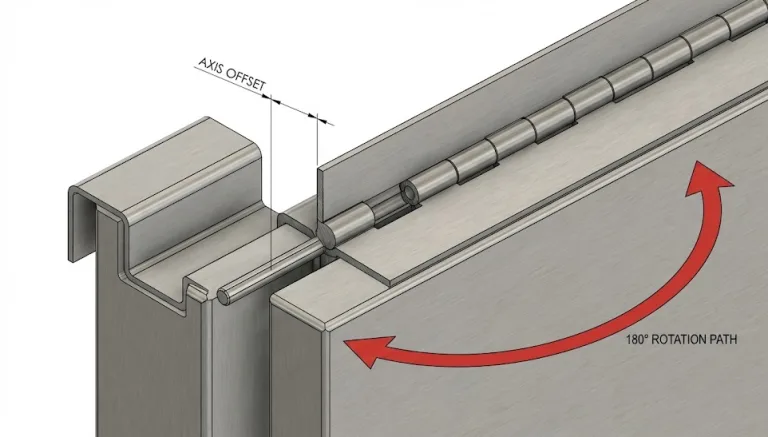

Concealed heavy duty hinges

Hidden heavy-duty hinges are more common in high-end equipment, hinges are not exposed after installation, beautiful and easy to clean.

It is important to note that the thickness of the door plate should be matched with the hinge specifications to avoid not being able to close completely after installation.

Hinges with buffer and self-closing function

Self-closing buffer hinges realize slow closing through hydraulic or spring mechanism to prevent the door from impacting.

Brand and model recommendation

Hettich (Hettich), Blum (Blum) known for high precision and long life.

HTAN (haitan), more cost-effective, suitable for users with limited budget.

Installation and commissioning guide

Preparation before installation

Measure the weight and size of the door panel to determine the number of hinges and load-bearing level.

When planning the installation position, make sure the hinges are evenly spaced to avoid uneven force.

Detailed hinge pre-installation preparation list can refer to the technical manual provided by the manufacturer.

Installation steps in detail

Mark the drilling position and use the special fixture to fix the hinge base.

Tighten the screws step by step according to the standard installation procedure of hinges to avoid misalignment caused by one-time locking.

Add grease (e.g. lithium grease) to reduce friction and prolong bearing life.

Commissioning and acceptance

- Test the opening and closing smoothness: the door body should stay at any angle without automatic sliding phenomenon.

- Check the sealing: after closing the door, test the gap with A4 paper, if it can’t be drawn out, it means the sealing is qualified.

Maintenance and troubleshooting

Daily inspection points

Clean the hinges and replenish the lubricant every 3 months, give priority to high temperature resistant silicone grease.

Regularly check whether the screws are loose, use torque wrench to re-lock according to the standard value (e.g. 1.5N-m).

Following a hinge routine maintenance program can reduce the probability of failure by 80%.

Common Failures and Solutions

- Opening and closing jamming: Clean the old grease and replace with new grease, if still ineffective then the bearing needs to be replaced.

- Rust and corrosion: Light rust with sandpaper grinding and spraying anti-rust paint, serious rust and corrosion need to be replaced as a whole.

- Loose shaking: recalibrate the installation position, increase the number of hinges if necessary.

FQA

Q:What is the difference between heavy duty hinge and common hinge?

A:Heavy-duty hinges have a stronger load-bearing capacity (usually more than 20 kilograms), and the use of rust-resistant materials, suitable for high-frequency or extreme environmental use.

Q:How often do the hinges of temperature humidity test box need to be replaced?

A:According to the frequency of use, it is generally replaced once in 5-8 years. If obvious deformation or strange noise is found, it should be overhauled immediately.

Q:What special tools are needed to install heavy-duty hinges?

A:Electric drill, torque wrench, level and positioning template need to be prepared to ensure installation accuracy.

Conclusion

Heavy-duty hinge is the core component to ensure the long-term stable operation of Temperature Humidity Test Box.

Through correct selection (such as high temperature and humidity resistant hinges), standardized installation (refer to the standard installation procedure of hinges) and regular maintenance (perform routine maintenance of hinges), the life of the equipment can be greatly extended.

Whether in the laboratory or on the production line, only by paying attention to every detail of the hinge can you ensure the accuracy of your experimental data and the efficient operation of your equipment.