HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Industrial handles serve as the primary point of contact between equipment and operators, requiring designs that balance rugged durability with ergonomic comfort. Beyond merely opening and closing mechanisms, they directly impact operational safety and user experience. Many users focus solely on appearance or dimensions during selection, overlooking critical factors like environmental adaptability, load capacity, and corrosion resistance. In reality, diverse application environments—such as food processing, healthcare, outdoor communications, and machinery manufacturing—impose vastly different requirements on handles. Therefore, targeted selection guidelines are essential for informed decision-making.

Basic Classification and Material Properties of Industrial Handles

From left to right:Stainless Steel Handles,Aluminum Alloy Handles,Nylon Handles,Zinc Alloy Handles

Before exploring specific applications, it is crucial to understand common handle types and their primary material characteristics.

Stainless Steel Handles:

High strength and corrosion resistance with smooth, easy-to-clean surfaces, ideal for environments with strict hygiene requirements. Common marine-grade 316 or 316L stainless steel contains high molybdenum content. After polishing and passivation, it exhibits exceptional chemical corrosion resistance, making it the preferred choice for food processing, pharmaceuticals, and medical equipment.

Aluminum Alloy Handles:

Lightweight yet strong with excellent thermal conductivity. Typically undergo anodized treatment for superior corrosion resistance. The anodized layer resists UV exposure and oxidation, enabling long-term use in harsh environments. Commonly used in electronics, cabinets, and machinery requiring lightweight structures.

Nylon/Plastic Handles:

Manufactured from engineering plastics like glass-fiber reinforced nylon (DuPont Celanyl® data), offering durability and light weight, offering durability and light weight. Their surfaces often feature anti-slip textures, providing a comfortable grip at a low cost. They are suitable for general industrial environments and control cabinets.

Zinc Alloy Handles:

Combine high strength with an attractive appearance, allowing for various surface treatments (plating, spraying, etc.). Durable zinc alloy handles are commonly found in machine tools, power distribution cabinets, and instrumentation where both strength and aesthetics are required.

Handle Types by Installation and Operation

Four different installation methods for industrial handles

| Handle Type | Key Features | Common Applications |

|---|---|---|

| Flush Handles | Install flush with the panel surface, eliminating protruding parts to save space and reduce collision risks. | Enclosed cabinets and sliding doors where a smooth appearance is required. |

| Protruding Handles | Extend beyond the panel surface, offering a secure grip and easy operation. | Various machine tools and industrial machinery, facilitating manual pulling or pushing. |

| Folding Handle | Can be folded 90° for storage and unfolded for use, increasing the grip surface area. This foldable design saves space while providing a secure grip. | Frequently moved equipment like mobile devices and transport containers. |

| Weld-on Handle | Directly welded to the equipment, offering a robust and durable structure capable of withstanding high loads. | Large doors or heavy-duty equipment housings, they offer high load capacity and extended service life. |

Application Scenario : Food Processing and Pharmaceutical Industries

The application of foldable handles in food processing equipment

For food and pharmaceutical sectors, hygiene and safety remain paramount. Handles in these environments must exhibit exceptional corrosion and rust resistance, with smooth, seamless surfaces that facilitate easy cleaning to prevent bacterial growth. Compliance with sanitary standards like FDA, EHEDG, or HACCP is typically required.

Key Requirements(in accordance with FDA, EHEDG, and HACCP guidelines):

- Must withstand strong acid/alkali cleaning and high-temperature sterilization

- Smooth surfaces without grooves to prevent contaminant accumulation

- Compliance with relevant food-grade standards

Recommended Types:

Prefer 316L stainless steel sanitary handles with polished or brushed finishes for chemical detergent resistance. Plastic-coated metal core handles are also common solutions, combining metal strength with plastic’s comfortable grip while facilitating easy cleaning.

Application Example:

Commonly used on equipment doors in food production lines, refrigerators, and stainless steel workstations. These door handles typically feature sanitary designs for frequent rinsing and disinfection.

Application Scenario : Outdoor and Harsh Environments

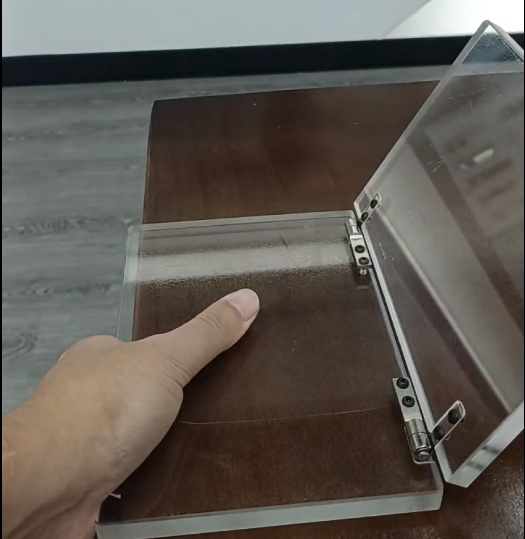

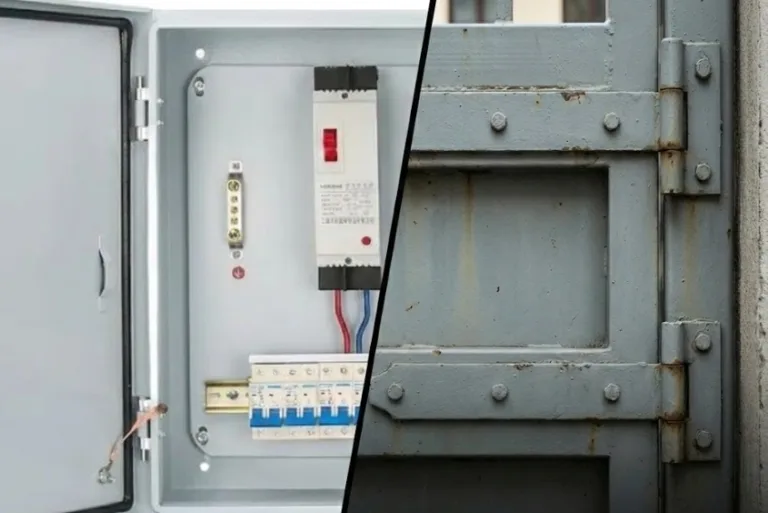

The application of foldable handles on outdoor explosion-proof distribution boxes

Compared to indoor use, outdoor and extreme environments demand higher weather resistance from handles. Handles may be exposed to corrosive conditions like intense UV radiation, acid rain, and sea salt spray, while significant temperature fluctuations can cause material aging and dimensional changes.

Environmental Challenges:

UV exposure accelerates plastic aging, thermal cycling causes material expansion and contraction, and salt spray/acid rain corrode metal surfaces. Thus, outdoor handles must possess weather resistance and corrosion resistance.

Recommended Types:

- Anodized Aluminum Alloy Handles: Lightweight and corrosion-resistant by nature; the anodized layer offers excellent weather resistance and wear resistance.

- Marine-Grade 316 Stainless Steel Handles: Mo-containing stainless steel exhibits strong resistance to marine corrosion; remains rust-free in extreme environments after passivation treatment.

- Glass-fiber reinforced nylon handles: Impact-resistant and aging-resistant (with UV additives), suitable for outdoor enclosures requiring vibration resistance.

Application Examples:

Such as outdoor electrical cabinet doors, base station equipment enclosures, traffic signal control cabinets, etc. Anodized aluminum or marine-grade stainless steel handles are commonly selected for these applications to withstand wind, sun exposure, and salt spray corrosion.

Application Scenario : Mechanical Manufacturing and Industrial Equipment

Handles used on CNC machines

In mechanical equipment, handle design prioritizes load-bearing capacity and frequent operation. Handles on machine tools and industrial transport equipment must withstand heavy loads and high-frequency use, demanding excellent mechanical strength and slip resistance.

Key Requirements:

- Must not loosen or deform under heavy pulling or frequent opening/closing, requiring sufficient mechanical strength and fatigue life

- Surfaces should feature effective anti-slip textures or ergonomic grips for comfortable operation and reduced fatigue

Recommended Types:

- Zinc alloy handles: Combine high strength with a refined appearance, suitable for medium loads and wear resistance.

- Welded steel handles: Directly welded to machine or equipment housings, offering robust reliability for large machine tools and heavy-duty installations.

- Folding handles: Facilitate handling and storage, ideal for industrial transport vehicles and mobile equipment.

Application Examples:

Machine tool control panels, control cabinet doors, industrial logistics transport vehicles, etc. These devices commonly use zinc alloy or steel handles to ensure stable, reliable operation and facilitate frequent opening/closing.

Application Scenario : Medical and Laboratory Equipment

The application of plastic handles on laboratory fume hoods

Medical environments demand both hygiene and resistance to chemical disinfection. Handles in these settings typically require antimicrobial and corrosion-resistant properties, with clean, rounded designs free of sharp edges to prevent cuts or snags.

Key Requirements:

- Antimicrobial surfaces and resistance to disinfectant corrosion are critical

- Handles must feature simple, smooth contours without sharp corners

- Secure installation is essential to prevent loosening from frequent use

Recommended Types:

- 316L stainless steel handles: Offer superior corrosion resistance and antibacterial properties, suitable for high-temperature, high-pressure sterilization.

- Ergonomic plastic handles (e.g., antibacterial ABS or polycarbonate): Materials inhibit bacterial growth while providing comfortable, slip-resistant grip.

- Flush-mounted handles with no protrusions: Reduce accidental collision risks, commonly used on medical carts and laboratory cabinets.

Application Examples:

Handles for medical carts, control levers for testing equipment, and cabinet door handles in laboratories all require easy cleaning and reliable durability. These handles often feature sterile designs and can undergo pre-sterilization treatment.

Selection Process and Practical Recommendations

After understanding different application requirements, follow these steps for selection:

Define usage environment and requirements:

Distinguish between indoor/outdoor use, operating temperature range, cleaning frequency, load capacity, etc. Only by clarifying environmental conditions can materials and designs be selected appropriately.

Determine installation method:

Choose the appropriate mounting method based on equipment structure. Opt for bolted fastening for quick removal, or welding/weld-in installation for enhanced durability. Consider installation ease and maintenance accessibility.

Consider ergonomics:

Select handle dimensions and shapes based on ergonomic principles. Grip surfaces should conform to hand contours to prevent fatigue or discomfort during frequent use. Ensure handle shapes won’t snag clothing or skin for enhanced safety.

Evaluate long-term maintenance and costs:

Weigh initial procurement costs against ongoing maintenance expenses. While premium materials require higher upfront investment, their extended lifespan and reduced maintenance needs lower total costs over time. Balance material longevity, spare part accessibility, and budget constraints during selection.

Conclusion

Though small, industrial handles are critical to equipment reliability, safety, and user experience. Different applications demand corresponding material and structural designs. Only by accurately understanding the operating environment and performance requirements can one select the truly suitable handle, thereby extending equipment lifespan and reducing maintenance costs. Whether in food processing, machinery manufacturing, or outdoor communications, adhering to scientific selection ensures safe and efficient equipment operation.

FAQ

Q: What factors should be considered when selecting industrial handles?

A: Operating environment, load capacity, corrosion resistance, ergonomics, and installation method. Use 316L stainless steel for food/pharmaceutical applications; opt for anodized aluminum or reinforced nylon for outdoor use.

Q: Why is stainless steel often recommended for food and pharmaceutical equipment?

A: 316/316L offers corrosion resistance and a dense surface for easy cleaning. Polishing + passivation enhances hygiene, meeting FDA, EHEDG, and HACCP requirements.

Q: Which handle materials are best suited for outdoor or harsh environments?

A: Anodized aluminum, 316 stainless steel, and glass-filled nylon resist UV exposure, salt spray, acid rain, and temperature fluctuations for long-lasting durability.

Q: What advantages do folding handles offer in industrial applications?

A: They fold flat at 90° to save space, provide secure grip when extended, minimize impact risks, and are ideal for portable devices, mobile containers, and outdoor electrical enclosures.

-1-768x768.png)