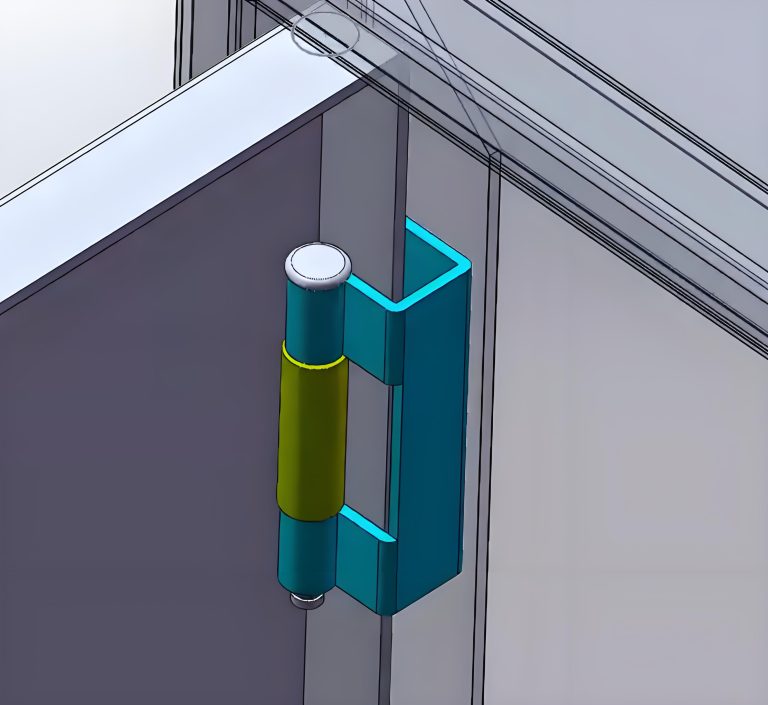

HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

The industrial hinge is often treated as an afterthought in equipment design, yet it defines the long-term integrity of the entire enclosure. Have you ever encountered this situation: The seals on an outdoor control cabinet fail because the door has sagged, causing expensive equipment to suffer water damage? Or, on vibrating equipment like generator sets, the door panel cannot close tightly—or even risks falling off—because the hinges have deformed?

In industrial scenarios, this is usually not an installation error, but a structural failure caused by insufficient hinge leaf thickness. Thin stamped hinges simply cannot withstand the long-term stress of industrial environments or the rebound pressure of sealing gaskets. They undergo microscopic deformation, leading to door misalignment.

Simply put, the core reason industrial hinges use thicker leaves is to increase the Section Modulus. When leaf thickness increases, the hinge’s resistance to shear force, bending stress, and deformation rises exponentially. A robust, thick leaf can not only support door weights of hundreds of kilograms but also ensure that the equipment maintains the precise alignment required for IP ratings even after tens of thousands of cycles.

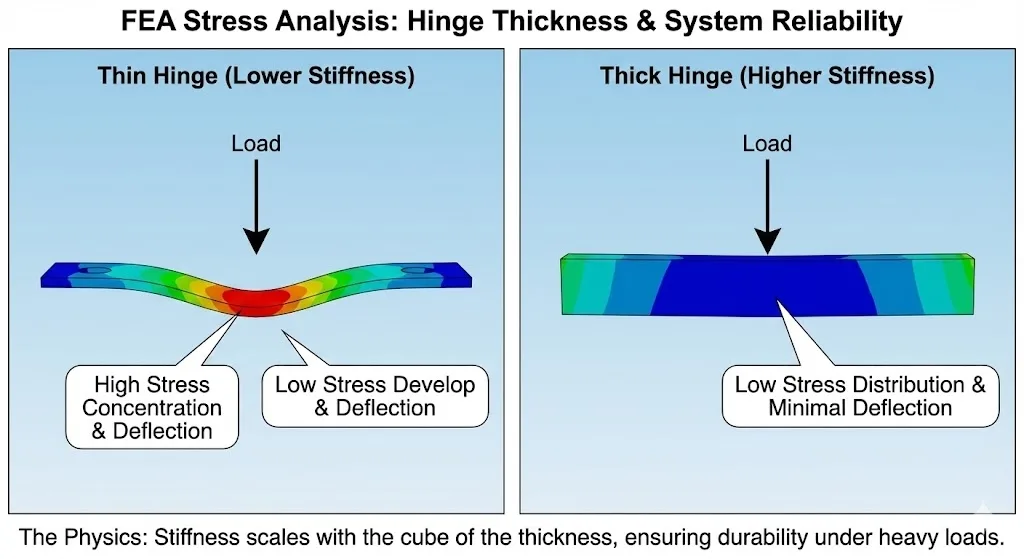

The Physics: How Thickness Determines System Reliability

Drastic Increase in Bending Stiffness

For a rectangular metal plate, bending stiffness has a non-linear relationship with thickness (theoretically, stiffness is proportional to the cube of the thickness). This means that even a slight increase in thickness results in a massive improvement in the hinge leaf’s ability to resist bending.

For example, increasing the leaf thickness from 3mm to 6mm can boost bending stiffness by roughly 8× (stiffness scales with thickness). A thicker cross-section is far less prone to leaf deformation under the door’s weight, helping maintain alignment and reducing curling or gap-widening over time. This is why listed fire door assemblies and industrial heavy-duty specifications often specify hinges with heavier gauges—commonly around 4.5mm or more, depending on the door rating, size, and hardware listing.

The Key to Maintaining IP Ratings (Sealing Performance)

This is an engineering detail that is often overlooked: IP65 or IP66 rated cabinets typically use sealing gaskets with high compression force. When the door is latched, the gasket generates a significant rebound force.

If the hinge leaf is too thin, the continuous push-back from the gasket will cause the leaf to undergo elastic deformation (flexing). This widens the gap on the hinge side, eventually leading to seal failure and the intrusion of dust or moisture. Thick leaves, with their high rigidity, act like a “rock” against this reaction force, ensuring the gasket remains in its correct state of compression.

Distributed Bearing of Shear Stress

Thicker leaves mean a larger cross-sectional area for shear resistance. This allows the weight of the door to be more effectively distributed to the pin and mounting screws. Thin hinges tend to create high stress concentrations at the pin knuckle and screw holes, which can lead to tearing or material fatigue over time. Thick leaves provide ample material surface area, reducing pressure per unit area and fundamentally eliminating the risk of single-point failure.

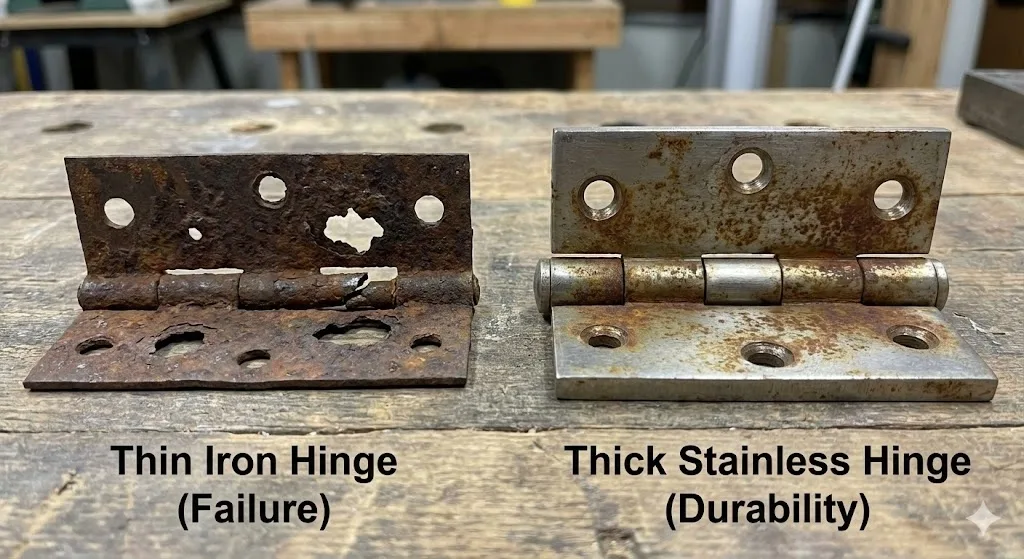

Durability and Lifespan: Combating Metal Fatigue

Zero Fatigue Under High-Frequency Use

Doors in industrial environments (such as factory workshop doors or automated assembly line guard doors) may be opened and closed hundreds of times a day. If the hinge leaf is too thin, every cycle produces a microscopic deformation invisible to the naked eye. Over time, this accumulation leads to metal fatigue cracks.

In contrast, solid heavy-duty leaves undergo almost no elastic bending under design loads. The stress from each cycle is far below the material’s fatigue limit. This is why heavy-duty hinges compliant with the ANSI/BHMA A156.1 standard can pass 200,000 cycle tests, whereas light-duty hinges often loosen after just a few hundred thousand cycles.

Avoiding Cumulative Plastic Deformation

Under long-term loading, thin leaves are prone to “creep”—permanent plastic deformation. Initially, this may just manifest as an uneven door gap, but after a few months, the door will sag and scrape the bottom frame. Thickness provides the necessary “elastic reserve,” ensuring the hinge remains dimensionally stable throughout its lifecycle, reducing the labor costs associated with frequent door alignment adjustments.

Environmental Factors: Corrosion and Impact Resistance

Corrosion Allowance:

In offshore wind, chemical, or coastal projects, corrosion is inevitable. Thicker leaves have more material that can be “sacrificed” to corrosion without compromising safety. If rust erodes the top 0.5mm of the surface, a 5mm thick hinge retains sufficient structural integrity. However, for a 2mm thin hinge, a 0.5mm loss could be a fatal structural weakening.

Impact Resistance:

Industrial sites are prone to accidents, such as forklift collisions or doors slamming shut due to strong winds. Thick leaves possess higher shock toughness and can absorb instantaneous energy without fracturing or severely twisting. They act like a “bumper” for the door system, protecting expensive frames and equipment from fatal damage during critical moments.

Installation and Welding Advantages

In heavy industry, hinges often require welding. Thin plates are extremely easy to burn through or deform under the high heat of welding. Hinges with ample thickness allow welders to apply higher current to achieve deep penetration, and their inherent rigidity resists thermal deformation, ensuring no post-weld calibration is needed. For bolted installations, thick leaves allow for deeper countersunk holes, letting screw heads sit perfectly flush without weakening the structure, resulting in a more secure connection.

Selection Guide: How to Choose Thickness Based on Application

To ensure a balance between safety and economy, please refer to the following chart for selection:

| Door Weight Class | Recommended Min. Thickness | Typical Application |

| Light Duty (< 50 kg) | ~3 mm (Standard) | Network server racks, light toolboxes, indoor access panels |

| Medium Duty (50–100 kg) | ~4 mm (Heavy Duty) | Outdoor electrical cabinets (IP65/66), HVAC access doors, medical equipment |

| Heavy Duty (> 100 kg) | ≥5 mm (Industrial Grade) | Diesel generator enclosures, specialty vehicle bodies, explosion-proof cabinets, shipping containers |

Note: For extra-wide doors or high-vibration environments (e.g., vehicles), it is recommended to upgrade one thickness level above the standard recommendation.

FAQ

Q: What is the fundamental difference between industrial hinges and standard hinges?

A: Besides the thickness usually being double (approx. 2-3mm vs. 4-6mm), industrial hinges typically feature precision bearings to reduce wear, larger diameter pins, and materials like 304 or 316 stainless steel to withstand harsh environments. They are designed for “engineering reliability,” not “home decoration.”

Q: Is a thicker hinge leaf always better?

A: Not necessarily. Excessive thickness adds unnecessary cost and weight, and may cause misalignment with standard door frame gaps. The correct approach is to choose a thickness with “sufficient redundancy” based on load and usage frequency, rather than infinitely increasing thickness.

Q: Why do heavy-duty models cost significantly more than hinges that look similar?

A: Material cost is only one factor. Heavy-duty thickened hinges typically require higher-tonnage stamping equipment, more precise molds, and stricter heat treatment processes. The higher price pays for an extremely low failure rate.

Conclusion

In procurement decisions, we often say: “Price is what you pay. Value is what you get.”

Choosing thickened heavy-duty industrial hinges may involve a slightly higher initial procurement cost, but the value delivered is immense. It eliminates downtime caused by sagging doors, guarantees the sealing safety of control cabinets, and extends the service life of the entire equipment. From a Total Cost of Ownership (TCO) perspective, a “Fit and Forget” thick-leaf hinge is actually the most cost-effective investment.

If your equipment needs to operate long-term in rigorous environments, ensure you choose tested and certified heavy-duty hinges. Thickness is not just a dimension; it is the cornerstone of industrial safety.