HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Choosing the right paddle latches for a sheet-metal door requires more than matching sizes—it depends on door structure, reinforcement, drilling accuracy, and compliance with safety standards. Understanding how the door is built and how different latch types interact with it is essential to achieving a secure, durable, and professional installation.

Understanding Sheet-Metal Door Structure and Paddle Latch Compatibility

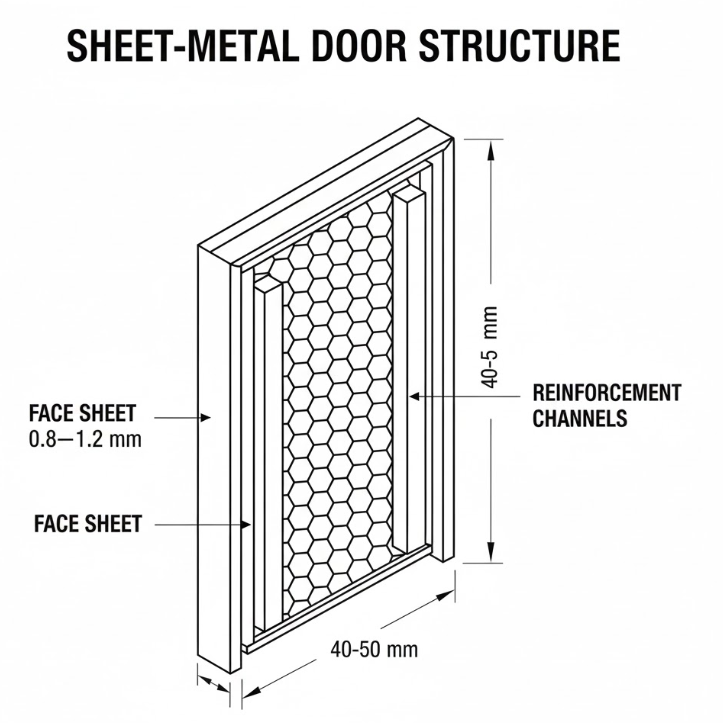

Sheet-Metal Door Construction Basics

Most sheet-metal doors contain the following components:

- Steel skins (0.8–1.2 mm)

- Honeycomb, rock wool, or PU foam core

- Optional reinforced mounting plate (≈3 mm steel)

Many commercial steel doors follow:

- ANSI/SDI-100 (Steel Doors and Frames)

- ANSI/SDI-105 (Installation Practices)

When no internal reinforcement exists, installers must compensate using rivet-nuts, spacers, or backing plates to prevent metal deformation.

Key factors affecting Paddle Latch compatibility:

- Door thickness (40–50 mm typical)

- Core material rigidity

- Existing reinforcement

- Latch backset requirements

- Required drilling clearance

Types of Paddle Latches (Materials, Functions, Durability)

Plastic Paddle Latches

- Lightweight

- Suitable for cabinets

- Not recommended for heavy steel doors

Zinc/Aluminum Alloy Paddle Latches

- Good cost-performance balance

- Electroplated for corrosion resistance

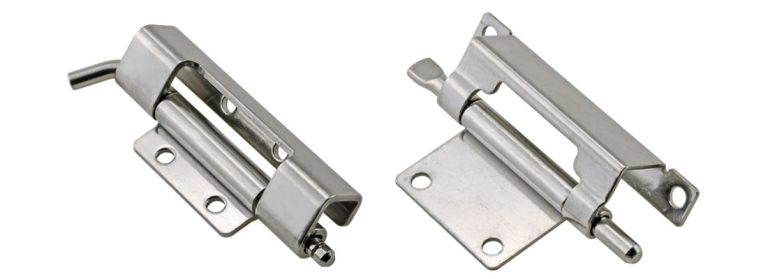

Stainless Steel Paddle Latches (304/316)

- Industrial-grade

- Ideal for exterior or high-frequency usage

- Many models comply with ANSI/BHMA A156.2 Grade 1

Locking vs. Non-Locking Paddle Latches

- Locking Paddle Latch uses replaceable or integrated cylinders

- Meets EN 1303 (Europe) or ANSI/BHMA A156.5 (US)

- Non-Locking Paddle Latch works as a pull handle with a latching mechanism only

Door Handing (Left/Right)

Confirm latch handing before drilling—although many Paddle Latches are reversible.

Compatibility Checklist Before Installation

✔ Door Thickness

Most Paddle Latches fit 30–50 mm door thickness. Check:

- Cylinder projection

- Spindle length

- Bolt reach

✔ Hole Requirements

Paddle Latch templates specify:

- Backset: 40 mm / 60 mm

- Main bore diameter: Ø25 mm – Ø50 mm

- Through-bolt spacing: varies by brand

✔ Mounting Method

Best for metal doors:

Through-Bolt Fastening

- Two long bolts clamp both sides

- Delivers superior strength

- Prevents panel distortion

Not recommended for metal doors:

Spring-clip fastening

- Intended for thin cabinet panels

✔ Reinforcement Solutions

If the door lacks a built-in support plate:

- Rivet nuts

- Anti-vibration washers

- Steel backing plates

Tools and Materials for Installing a Paddle Latch

Essential Tools

- Phillips & flat screwdrivers

- Variable-speed drill/driver

- HSS or bi-metal hole saw (25–50 mm size)

- Impact drill for thick metal skins

Precision Measuring Tools

- Tape measure

- Spirit level / laser level

- Silver paint pen

- Center punch

Materials

- Zinc paint or rust-preventive spray

- Spacers or washers

- Rubber seal (outdoor installations)

Measurement and Positioning (Critical Accuracy Phase)

Standard Height for Paddle Latches

Per building codes:

- ICC/IBC: 34–48 in (864–1219 mm)

- ADA: ideal at 36–40 in

Typical installation: 1 meter (39–40 in) from finished floor.

Marking the Paddle Latch Location

Steps:

- Mark height on both sides of the door

- Extend horizontal level line

- Measure inward for backset

- Mark central bore hole

- Mark upper & lower through-bolt holes

- Center-punch every location

How to Avoid Measurement Errors

- Do not trust door frame alignment

- Drill a pilot hole first

- Transfer marks from outside → inside using pilot hole

- Double-check both sides before using a hole saw

Drilling Procedures for Paddle Latch Installation

Main Bore Hole Drilling

- Drill 3 mm pilot hole

- Mount hole saw and apply cutting oil

- Drill at low–medium speed

- Slow down before breakthrough to protect steel skin

Relevant safety standards:

Drilling Through-Bolt Holes

- Use appropriate drill bit for M4/M5 hardware

- Keep drill perfectly vertical

- Hole size = 85–90% of screw outer diameter

Deburring and Rust Protection

- File rough edges

- Vacuum all metal chips

- Apply zinc-rich primer or anti-rust spray

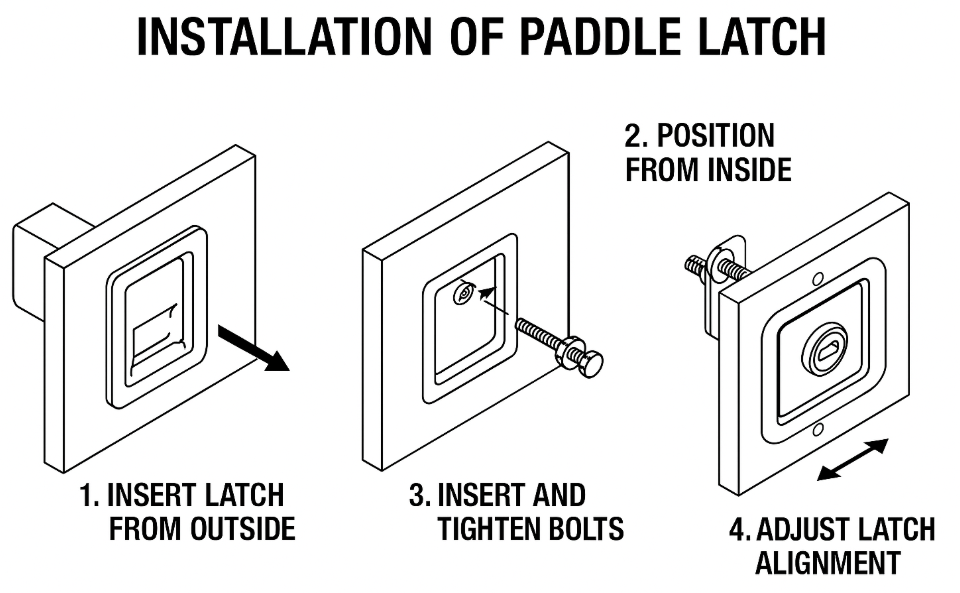

Installing the Paddle Latch Assembly

Insert Exterior Paddle Latch Assembly

- Insert paddle housing through main bore

- Check latch tongue alignment

- Confirm correct handing

Attach Interior Assembly & Tighten Through-Bolts

- Align spindle and cylinder tailpiece

- Insert the two long bolts

- Tighten in alternating pattern

- Use spacers if necessary to prevent bending

Adjust Latch Movement and Handle Spring

Verify:

- Smooth action

- Clean latch retraction

- Firm spring return

If not smooth:

- Re-center latch body

- Apply silicone or graphite lubrication

- Adjust tension screws (if applicable)

Functional Testing and Safety Validation

Operation Testing

Cycle door 20+ times:

- Paddle movement smooth

- Latch retracts fully

- Door closes snugly

If slamming is required → adjust strike plate.

Structural Tightness Check

Ensure:

- No wobbling

- No rattling

- No metal flexing

- No screw loosening

Solutions:

- Thread-locker

- Larger screws

- Rivet nuts

Safety & Fire-Door Considerations

For fire doors:

- Only use Paddle Latches certified for UL 10C or EN 1634-1

- Avoid damaging fire-resistant core

- Seal exposed cavities with fire-rated sealant

Test handle usability for:

- Elderly

- Children

- Low-force operation

Maintenance Guidelines for Paddle Latch Longevity

Regular Screw Tightening

Intervals:

- High-traffic doors: every 3 months

- Residential: every 6–12 months

Lubrication

Use:

- Silicone spray

- Graphite powder

Avoid:

- Engine oil

- Conventional grease

- WD-40 inside cylinders

Rust Prevention

For coastal/humid areas:

- Use 316 stainless steel Paddle Latches

- Select products meeting EN 1670 Grade 3+

- Apply zinc spray to drilled surfaces

Cold-weather maintenance:

- Anti-freeze lubricant

- Keep keyways dry

Troubleshooting: Paddle Latch FAQ

Why is the Paddle Latch handle loose?

Causes:

- Loose set screw

- Worn spindle

Fix:

- Retighten screw + apply thread-locker

- Replace spindle

Latch does not return properly

Causes:

- Spring deformation

- Latch misalignment

Fix:

- Re-center latch

- Lubricate

- Replace spring

Noise during opening/closing

Causes:

- Dry hinges

- Internal metal friction

Fix:

- Lubricate hinges

- Lubricate latch mechanism

- Tighten all screws

Conclusion

A properly installed Paddle Latch ensures durability, secure operation, and smooth user experience on any sheet-metal door. By following the technical procedures and standards referenced here—including ANSI/BHMA, ICC/IBC, ADA, UL, and EN—installers can achieve professional-grade results suitable for industrial, commercial, or residential applications.

Regular maintenance and correct installation are the keys to reliable long-term performance.