HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Concealed hinges are a versatile and essential hardware solution, widely used in modern homes, commercial spaces, and industrial areas. Their clever design allows them to be completely hidden within door panels or cabinets, combining both aesthetics and practicality. This comprehensive guide provides everything you need to know about concealed hinges, from their core requirements and types to quality assessment, selection tips, application scenarios, installation, and maintenance.

I. Core Requirements of Concealed Hinges

Structure Design

Concealed hinges are composed of precision parts like connecting plates, rotating shafts, and adjusting screws. They ensure smooth opening and closing while supporting three-dimensional adjustments (up/down, left/right, front/back) to fit various installation environments.

Load-Bearing Capacity

- Civilian Grade: 30-50kg (ideal for cabinets, closets, etc.).

- Industrial Grade: 80-150kg or more (for electrical cabinets, equipment hatches, etc.).

Material Selection

- 304 Stainless Steel: Corrosion-resistant and suitable for humid environments.

- Aluminum Alloy: Lightweight with good mechanical properties.

- Zinc Alloy: Cost-effective but with weaker corrosion resistance.

Opening and Closing Angle

Typically 90°-180°, with industrial-grade hinges reaching up to 270°. They also support any-angle hovering for added flexibility.

Ease of Installation

Professional tools such as a 35mm cup hole drill and leveling device are required. Some products offer quick-installation features to simplify the process.

Maintenance and Adaptability

- Regular cleaning with a neutral cleaner is recommended to avoid damage from corrosive liquids.

- Hinges should be adaptable to different door thicknesses (16-25mm) and installation methods (full cover, half cover, built-in).

II. Common Types and Applicable Scenarios

| Type | Feature | Applicable Scenes |

|---|---|---|

| Embedded Hidden Hinge | Completely hidden, 90°-180° opening angle | Cabinets, closets, and other household scenes |

| Bouncing Hidden Hinge | Automatic closing function, load-bearing ~30kg | Kitchen overhead cabinets, bathroom cabinets |

| Folding Hidden Hinge | Foldable door panels, space-saving | Invisible bed systems, folding door systems |

| Heavy-Duty Industrial Hinges | Load capacity 80-150kg+, high protection level (e.g., IP66) | Electrical cabinets, marine hatches |

III. Quality Judgment Standards

Material Testing

- 304 Stainless Steel: Must pass a non-magnetic test.

- Aluminum Alloy: Surface should be smooth without oxidation traces.

Structural Strength

- Ball bearing diameter ≥3mm

- Thickness of connecting rod ≥2mm

Surface Treatment

- Typically uses electrophoretic coating or powder spraying processes

- Plating thickness ≥8μm

- Passes the 2H pencil hardness test

Durability Testing

- Static load-bearing capacity at 1.5 times the rated load

- Dynamic opening and closing for over 100,000 cycles

- Salt spray test ≥48 hours (to assess corrosion resistance)

IV. How to Choose the Right Concealed Hinge?

Material Selection

- Humid Environments: Choose 304 stainless steel.

- Lightweight Demand: Opt for aluminum alloy.

Load-Bearing and Opening Angle

- For industrial scenes, select high load capacity (≥80kg) and large opening angles (≥180°).

Protection Grade

- Outdoor or harsh environments require IP54/IP66 ratings.

Brand Recommendations

- High-End: Hettich (Germany), Blum (Austria)

- Cost-Effective: HTAN (China)

V. Installation Steps and Precautions

Tool Preparation

- 35mm cup hole drill

- Level

- Screwdriver

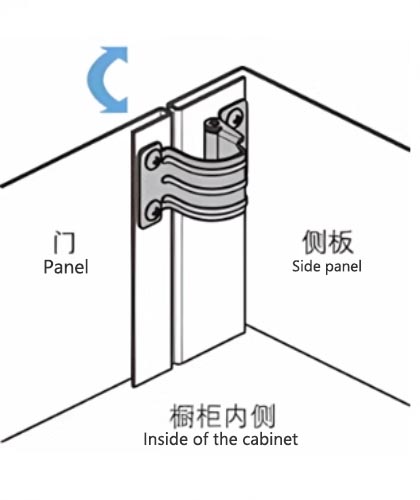

Installation Process

- Positioning: Mark the position 37mm from the door edge.

- Drilling: Drill 35mm cup holes vertically.

- Fixing Hinge: Adjust the 3D screws to align the door panel.

Precautions

- Ensure door thickness is ≥18mm.

- Avoid over-adjustment of screws to prevent damage to parts.

VI. Daily Maintenance Tips

Cleaning

- Use a neutral cleaner and soft cloth to wipe. Avoid acidic solutions.

Lubrication

- Apply a silicone-based lubricant to the rotating shaft annually.

Check Screws

- Regularly tighten screws to prevent loosening.

VII. FAQ

Q: Why are my hinges rattling?

A: Check for bearing wear or replenish lubricant.

Q: Why does the door shake after installation?

A: Ensure the panel thickness is ≥18mm and recalibrate the installation position.

Q: How do I choose the right protection level?

A: Use IP54 or above for outdoor applications, and IP66 for industrial environments.

Conclusion

Concealed hinges are a crucial accessory for enhancing both the aesthetics and functionality of any space. Their lifespan can be significantly extended through careful selection, proper installation, and regular maintenance. Whether for domestic or industrial use, choosing a quality product ensures optimum performance and longevity.