HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

-

+86 13720060320

-

julius@haitangs.com

A Comprehensive Guide to Purchasing In-Line Torque Hinges

With the increasing popularity of flip-cover electronic devices, in-line torque hinges play a crucial role as a core component. This guide provides an in-depth look at key factors to consider when purchasing these hinges, using the HG302-1W in-line damping hinge as an example. We will cover product specifications, selection criteria, maintenance, and storage to help you choose the right torque hinge for your needs.

1.Product Introduction

2.Key Factors for Selecting a Torque Hinge

Material Selection

Torque Performance

Lifespan and Torque Decay

Manufacturing Quality and Environmental Compliance

Customization Options

3.Maintenance Storage and Transportation

Maintenance Tips

Storage and Transportation

4.Conclusion

Torque Specifications for Other Sizes of Straight Torque Hinges

1. Product Introduction

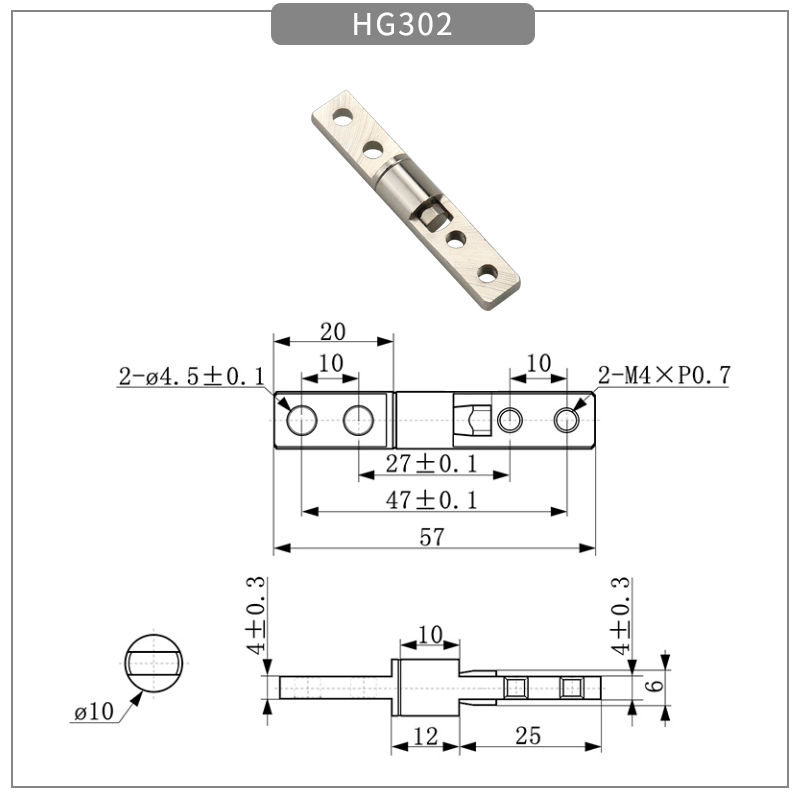

- The HG302-1W in-line damping hinge is designed specifically for flip-cover electronic devices.

- Made from high-quality 12L15 material, it is compact and easy to integrate into various digital products.

- This hinge offers stable torque performance, a lifespan of up to 3,000 cycles, and a torque decay rate of no more than 20%, ensuring long-term durability.

- Additionally, manufacturers like HTAN provide custom torque hinge solutions tailored to specific customer requirements.

2. Key Factors for Selecting a Torque Hinge

Material Selection

- High-quality materials are essential for stable hinge performance.

- The HG302-1W hinge uses 12L15 material, known for its mechanical strength and corrosion resistance.

- When selecting a hinge, consider material properties such as strength, hardness, wear resistance, and corrosion resistance to ensure long-term stability.

Torque Performance

- Torque is a critical specification that directly impacts the ease and stability of the flip mechanism.

- The HG302-1W hinge provides a torque value of 0.3N.m-5.0N.m.

- Choose a torque range that aligns with your application needs to ensure smooth operation and prevent product damage.

Lifespan and Torque Decay

- A hinge’s lifespan and torque decay rate determine its durability.

- The HG302-1W hinge guarantees 3,000 cycles with a torque decay rate below 20%.

- Look for products with reliable lifespan testing and low torque decay rates to ensure long-term performance.

Manufacturing Quality and Environmental Compliance

- Advanced manufacturing processes ensure precision and smooth hinge surfaces.

- The HT302-1W hinge is crafted with high-precision machining, eliminating burrs and ensuring accurate dimensions.

- With growing environmental concerns, verify if the hinge meets environmental standards, such as using eco-friendly materials and obtaining relevant certifications.

Customization Options

- Different applications require different hinge specifications.

- HTAN offers customization services to tailor torque hinges to specific needs.

- When selecting a manufacturer, assess their customization capabilities and service range to ensure they can meet your unique requirements.

3. Maintenance, Storage, and Transportation

Maintenance Tips

- Regular maintenance extends the lifespan of torque hinges.

- Use a mild cleaner to wipe hinge surfaces, removing dust and enhancing appearance.

- For components like hinges and sliding rollers, apply a drop or two of lubricant every six months to maintain smooth operation and prevent wear.

Storage and Transportation

- Proper storage and handling are essential to prevent damage.

- HG302-1W hinges are packaged in specialized blister boxes for shock and pressure resistance.

- Store hinges in a dry, well-ventilated area with desiccants to prevent moisture buildup.

- During transportation, handle with care and implement waterproof packaging to protect against damage.

4. Conclusion

As a key component in flip-cover electronic devices, in-line torque hinges require careful selection and proper maintenance. This guide has provided detailed insights into the HG302-1W damping hinge, including material selection, torque performance, lifespan, manufacturing quality, and customization options. By considering these factors and following proper maintenance and storage practices, you can ensure long-lasting and reliable hinge performance.

Torque Specifications for Other Sizes of Straight Torque Hinges

| norm | torsion(N.m) | typology |

|---|---|---|

| 4*11 | 0.1 | Straight Hinge |

| 4*15 | 0.1 | Straight Hinge |

| 4*22 | 0.25 | Straight Hinge |

| 4×27.5 | 0.1~0.2 | Straight Hinge |

| 5*20 | 0.1 | Straight Hinge |

| 6*18 | 0.1 | Straight Hinge |

| 6*36 | 0.3 | Straight Hinge |

| 6*36 | 0.5 | Straight Hinge |

| 6*36 | 1.0 | Straight Hinge |

| 6*36 | 0.3 | Inline Hinge with Counterbore |

| 6*36 | 0.6 | Inline Hinge with Counterbore |

| 8*43.5 | 1 | Straight Hinge |

| 8*43.5 | 1.5 | Straight Hinge |

| 8*57 | 1.0 | Straight Hinge |

| 8*57 | 1.5 | Straight Hinge |

| 8*57 | 2.0 | Straight Hinge |

| 9*65 | 1.5 | Straight Hinge |

| 10*57 | 0.5 | Straight Hinge |

| 10*57 | 1 | Straight Hinge |

| 10*57 | 1.5 | Straight Hinge |

| 10*57 | 2 | Straight Hinge |

| 10*57 | 3 | Straight Hinge |

| 12*34.5 | 2 | Straight Hinge |

| 12*56.5 | 0.3 | Straight Hinge |

| 12*56.5 | 3 | Straight Hinge |

| 12*60 | 0.7 | Straight Hinge |

| 12*60 | 1.0 | Straight Hinge |

| 12*60 | 1.5 | Straight Hinge |

| 12*60 | 2.0 | Straight Hinge |

| 12*70 | 3 | Straight Hinge |