HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

-

+86 13720060320

-

julius@haitangs.com

What Is a Cabinet Door Torque Hinge? Definition, Working Principle, Applications & Installation Guide

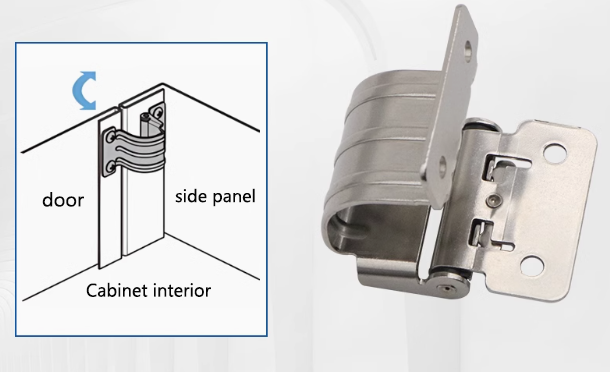

Cabinet door torque hinge is the core hardware accessory connecting the cabinet and door panel, undertaking the function of supporting the door panel and controlling the opening and closing angle.

With the built-in friction mechanism, the cabinet door torque hinge can adjust the rotational resistance to realize the stable hovering of the door panel at any angle.

This makes them ideal for medical equipment, industrial cabinets, special vehicles, and other applications requiring precise control.

Definition and Principle of Torque Hinge

What Is a Torque Hinge?

A torque hinge controls the door’s opening/closing angle and speed by adjusting internal resistance.

Its core function is “torque output” – applying controlled friction to ensure the door stays in any desired position without external support.

How Does a Torque Hinge Work?

- Friction plate structure: Friction is controlled by pressing a plate with an adjustment screw.

- The greater the pressure, the higher the resistance during door rotation.

Understanding Torque: Newton-Meter (N·m)

The torque unit Newton meter (N·m) = Force (Newtons) × Arm Length (meters).

Example: 1 N·m = 1 Newton applied at a 1-meter lever.

In real applications, cabinet door torque hinges typically adjust within 0 to 3.0 N·m, suitable for everything from lightweight wooden doors to heavy-duty metal doors.

Torque Adjustment Range and Adaptability

Why Torque Adjustment Matters

The torque must match the weight, size, and use of the door:

- Light doors (0–1.5 N·m): <5 kg (e.g., lockers, mirror cabinets)

- Medium doors (1.5–2.5 N·m): 5–15 kg (e.g., bookcase doors)

- Heavy-duty doors (2.5–3.0 N·m): >15 kg (e.g., display cabinet doors)

How to Select the Right Torque Value

Calculate door weight and center of gravity distance

Use formula:

Torque = Weight × Distance to hinge

Add a 20%–30% safety margin to handle impact or frequent use

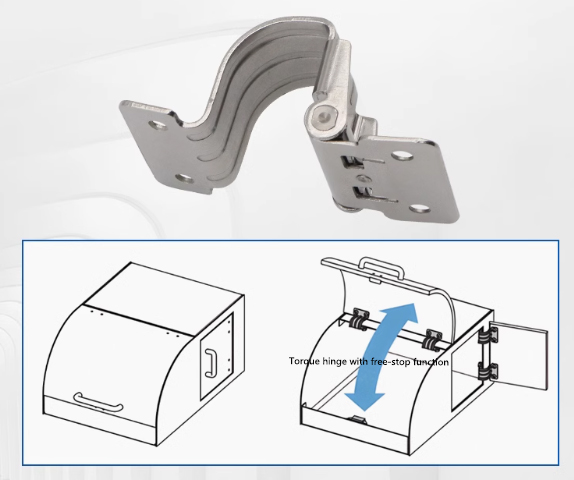

Multi-Positioning Function

What Is Multi-Positioning?

Unlike traditional damping hinges that only fix at certain angles (e.g., 90°, 175°), torque hinges:

- Provide suspension at any angle through continuous resistance

- Allow for flexible positioning from 30° to 180°

User Experience Benefits

- Safety: Prevents accidental door closure and pinching

- Convenience: One-hand operation without extra support structures

Application Scenarios

Medical Equipment Cabinet Doors

- Require frequent opening and specific-angle suspension

- Torque hinges prevent unintentional closure

- Protect medical staff and sensitive instruments

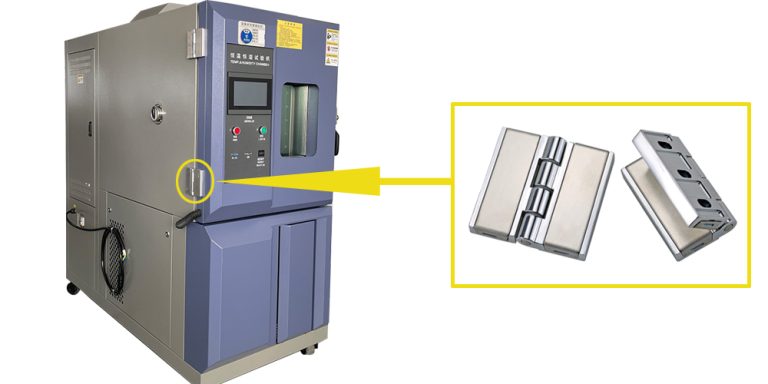

Industrial Automation Equipment

- Cabinet doors face frequent opening in vibration-heavy environments

- Torque hinges (2.5–3.0 N·m) ensure reliable positioning

- Enhance operational safety and efficiency

Special Vehicles & Rail Transportation

- Vehicle motion causes vibration and tilting

- Torque hinges stabilize the door through adaptive resistance

- Suitable for military vehicles, high-speed trains, etc.

Installation and Usage Guide

Installation Tips

- Initial setting: Start with minimum torque, adjust gradually

- Environment: For high-humidity or corrosive settings, choose stainless steel hinges and apply anti-rust lubricants

Testing & Adjustment

- Open/close the door slowly to test natural stopping

- If it slips, fine-tune the torque screw

- Maintenance: Check every 6 months for wear on friction plates or springs

Key Advantages of Cabinet Door Torque Hinges

| Benefit | Description |

|---|---|

| ✅ Safety | Prevents accidental closure and injury |

| ✅ Flexibility | Supports hovering at any angle |

| ✅ Durability | Long life with high-quality materials like cold-rolled steel or stainless steel |

| ✅ Low Maintenance | Modular structure simplifies upkeep |

Conclusion

Cabinet door torque hinges offer precise control, enhanced safety, and a superior user experience, making them a top choice for:

- Medical

- Industrial

- Transportation sectors

Through technological upgrades, they effectively solve the limitations of traditional hinges and meet the demands of modern applications.

-768x768-1.png)