HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

-

+86 13720060320

-

julius@haitangs.com

Cabinet Handles for Steam and Oven Doors

Looking for the right cabinet handles for a hot environment in your kitchen, lab or industrial facility? Whether it’s steam equipment, oven doors or other high-temperature scenarios, ordinary handles are prone to warping, corrosion or burning.

In this article, we’ll take a closer look at how to choose heat-resistant cabinet handles that combine safety and comfort.

Through the material, design and scene analysis, to help you find a truly suitable solution.

High Temperature Environment Application Requirements

In the selection of high temperature environment with cabinet handles before, must be clear about the specific needs of the use of the scene.

For example:

- Kitchen equipment: oven, steamer door needs to be opened and closed frequently, the handle must be high temperature and anti-scald.

- Industrial steam equipment: long-term contact with high-temperature steam, the requirements of corrosion-resistant materials, structural stability.

- Laboratory ovens: need to meet hygiene standards, easy to clean and resistant to extreme temperatures.

The common challenges of these scenarios are: high temperature, high humidity, high frequency use.

If you choose the wrong puller, it may lead to deformation, cracking or safety hazards.

The Double Challenge of Temperature and Humidity

Key Problems:

- Temperature fluctuations: Oven door handles may be instantly exposed to temperatures above 200°C. Ordinary plastics will soften and metals may conduct heat and burn.

- Humidity erosion: the high humidity environment of steam equipment will accelerate the metal rust or plastic aging.

Solution:

Choose high-temperature resistant materials (e.g. stainless steel, special engineering plastics) and match them with moisture-resistant designs (e.g. sealed structures or rust-resistant coatings).

According to ASTM G48 standards, 316 stainless steel offers superior resistance to pitting and crevice corrosion in chloride environments compared to 304 stainless steel (ASTM)

Balance Between Ergonomics and High-Frequency Use

Potential Issues:

- Grip discomfort: prolonged operation may cause hand fatigue.

- Safety hazard: High surface temperatures may burn the skin.

- Inconvenient to operate: the angle or size of the handles do not meet the human body habit.

Recommended Features:

- Thermal insulation design: reduce heat transfer to the contact surface.

- Comfortable grip: Shape and size that conforms to the curve of the hand.

- Anti-slip surface: avoid slippage when operating with wet hands.

As per ISO 9241-410 ergonomic design standards, handle surfaces intended for hand contact should not exceed 43°C to prevent discomfort or injury (ISO)

Handle Selection Guide: Core Material Analysis

Material is the basis for determining the performance of cabinet handles for high temperature environments.

Below are three common high-performance materials:

Stainless Steel: Durability and Cost-Effective Choice

- Recommended models: 304 stainless steel, 316 stainless steel

- Temperature range: -200°C to 800°C (short-term peak)

- Benefits: Corrosion resistance, high strength, easy to clean, suitable for commercial kitchens and industrial equipment.

- Cautions: Pure metal may conduct heat, need to be matched with insulated structure.

AISI 316 Stainless Steel Material Data Sheet

Source: MatWeb – AISI Type 316 Stainless Steel

| Category | Property | Value |

|---|---|---|

| Physical Properties | Density | 8.00 g/cm³ |

| Melting Point Range | 1370 – 1400 °C | |

| Electrical Resistivity (20°C) | 0.0000740 ohm-cm | |

| Thermal Expansion (0–100°C) | 16.0 µm/m-°C | |

| Thermal Conductivity (100°C) | 16.3 W/m·K | |

| Specific Heat Capacity | 0.500 J/g·°C | |

| Max Operating Temperature (Air) | Continuous: 925°C / Intermittent: 870°C | |

| Magnetic Permeability (at RT) | 1.008 | |

| Mechanical Properties | Ultimate Tensile Strength | 580 MPa |

| Yield Strength (0.2% offset) | 290 MPa | |

| Elongation at Break | 50% | |

| Elastic Modulus | 193 GPa | |

| Hardness (Rockwell B) | 79 | |

| Chemical Composition | Carbon (C) | ≤ 0.08% |

| Chromium (Cr) | 16 – 18% | |

| Nickel (Ni) | 10 – 14% | |

| Molybdenum (Mo) | 2 – 3% | |

| Manganese (Mn) | ≤ 2.0% | |

| Silicon (Si) | ≤ 1.0% | |

| Phosphorus (P) | ≤ 0.045% | |

| Sulfur (S) | ≤ 0.030% | |

| Iron (Fe) | Balance |

Aluminum Alloy: Lightweight and Rust-Resistant Advantages

- Temperature range: -50°C to 200°C

- Advantages: 30% lighter than stainless steel, surface oxide layer protects against corrosion, suitable for weight-sensitive equipment.

- Disadvantages: Possible deformation at extreme temperatures, need to avoid direct contact with open flames.

High Temperature Engineering Plastics

- Recommended models: PEEK (polyether ether ketone), PPS (polyphenylene sulfide)

- Temperature range: PEEK up to 250°C, PPS about 220°C

- Advantages: electrical insulation, anti-burning, chemical resistance, suitable for laboratory or medical equipment.

- Disadvantages: Higher cost and fewer color options.

PEEK is widely used in aerospace and medical industries for its exceptional heat and chemical resistance. See Victrex PEEK Technical Data.

Installation Structure and Functional Design Points

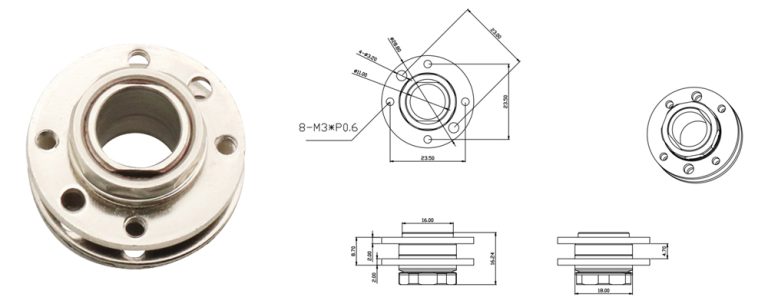

Hidden Screws and Insulating Gaskets

- Concealed screws: Avoid direct contact with high temperature areas and prevent heat transfer to the surface of the handle through the metal.

- Insulating spacer: Adding ceramic or mica spacer between the screw and the handle to further block heat transfer.

Thickened Grip Area and Double Layer Construction

- Thickened design: Increase the thickness of the grip area of the handle to minimize heat transfer from the door panel to the hand.

- Double-layer heat insulation: Some high-end handles adopt the structure of “metal inner layer + plastic outer layer”, which combines strength and heat prevention.

Recommendation of Popular Types and Applicable Scenarios

Industrial-Grade Door handles

- Features: All-metal structure (stainless steel or cast iron) + ceramic fiber insulation.

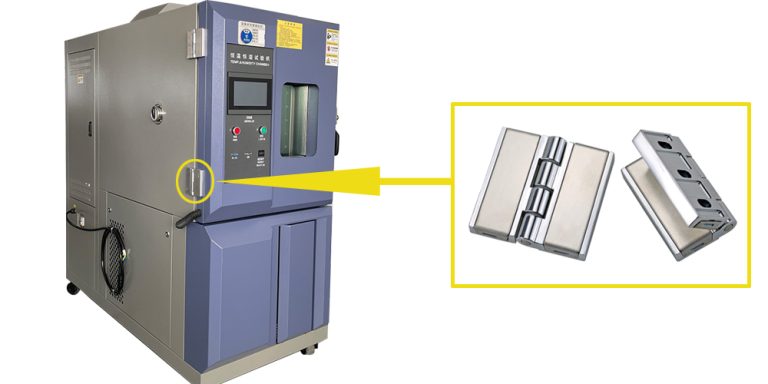

- Applicable scenarios: industrial steam cabinets, laboratory autoclave equipment.

- Core requirements: extreme temperature resistance, impact resistance, long life.

Commercial Kitchen Oven Handle

- Features: stainless steel body + silicone anti-slip grip, anti-fingerprint surface treatment.

- Applicable scenes: restaurant oven, bakery steamer.

- Core requirements: frequent switching, anti-oil, easy to clean.

“Design is not just what it looks like and feels like. Design is how it works.” — Steve Jobs

Medical/Laboratory Equipment Handle

- Features: PEEK material + seamless design to avoid bacteria residue.

- Applicable scenes: biological safety cabinet, high temperature sterilization equipment.

- Core requirements: sterile environment, chemical reagent resistance, electrical insulation.

Compliant with FDA and ISO 13485 standards for medical-grade materials (FDA)

| Compliance | Standard/Regulation | Details |

|---|---|---|

| FDA | FDA 21 CFR 820 | Compliant with FDA regulations for medical devices, ensuring the material is safe and effective for medical use. |

| ISO 13485 | ISO 13485:2016 | Compliant with the international standard for medical device quality management systems (QMS). Ensures PEEK used in medical devices meets rigorous standards. |

| Material Classification | Medical-Grade | Suitable for implants, medical instruments, and devices that require biocompatibility and regulatory approval. |

FAQ

Q: How high temperature can the puller withstand?

A: Different materials have different temperature resistance:

- Stainless steel: 300°C long term, 800°C short term.

- PEEK plastic: 250°C long term.

- Aluminum: 200°C long term.

Recommendation: choose according to the maximum temperature of the equipment + 20% margin.

Q:What material is the most corrosion-resistant puller?

A:Ranking: 316 stainless steel > 304 stainless steel > anodized aluminum alloy.

If the environment contains strong acids or alkalis, PEEK plastic is preferred.

Q:How can I tell if a pull handle is suitable for steam environments?

A:Is the material labeled “high temperature resistant” or “steam corrosion resistant”?Whether the structure has a moisture-proof design (e.g., sealing ring).Whether the user manual clearly supports steam equipment.

How to Choose the Right High-Temperature Cabinet handles for You

Depending on the Type of Appliance

- Built-in home oven: choose aluminum alloy handle with silicone anti-scald layer, beautiful and lightweight.

- Industrial steam cabinets: prioritize heavy-duty handles with stainless steel + insulation.

- Laboratory equipment: consider PEEK material to avoid contamination of the experimental environment.

Adjustment According to User Habits

- Gloved operation: choose large-size handles (length > 12 cm) for easy gripping.

- One-handed operation: recommend L-type or U-type handles, labor-saving and easy to apply force.

- High-frequency use: add spring-assisted structure to reduce the force of opening and closing the door.

Conclusion

Choosing an excellent high-temperature resistant cabinet handle requires a balance of material properties, structural design and actual use requirements.

Whether it’s steam equipment, oven doors or lab tools, the core goal is the same: to maintain durability in extreme environments while making operation safer and more comfortable for the user.

With the guide in this article, you can clarify:

- The advantages and disadvantages of different materials and the scenarios for which they are suitable.

- How to improve insulation and ergonomics through structural design.

- Make precise choices based on specific equipment and usage habits.

Finding the perfect combination of heat-resistant and ergonomic handles will not only extend the life of your equipment, but also improve efficiency and safety.