HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Cam Latch is a mechanical device for quick locking and unlocking by rotating the handle.

Consisting of a handle, cam and housing, the cam is actuated by rotation to extend and retract, thereby securing or releasing doors, flaps and other components.

Why Is Cam Latch Important?

Cam Latch does more than simply open and close doors. In industrial installations, it plays a critical role:

- Ensures dustproof and watertight sealing for electrical cabinets

- Protects precision instruments from vibration

- Enhances corrosion resistance of outdoor equipment

- Meets strict hygiene requirements for medical equipment

- Provides safe and efficient locking in both routine and emergency operations

Basic Structure and Working Principle of Cam Latch

Core Components

| Component | Description |

|---|---|

| Handle | User-operated rotating part, commonly made of stainless steel or engineering plastics. |

| Tongue (Cam) | Rotates and extends to achieve locking. The shape and length influence the load capacity. |

| Housing | Protects the internal mechanism, often designed to be dustproof and waterproof. |

Working Mechanism

Cam Latch utilizes a Rotary Latch System:

- Locking: Turn handle clockwise → Cam extends → Snaps into fixing slot

- Unlocking: Turn handle counterclockwise → Cam retracts → Releases latch

Common Types of Cam Latch

| Type | Features & Use Case |

|---|---|

| Compression Type | Includes a spring for added pressure and shock resistance. |

| Waterproof Type | Includes sealing and achieves IP67 rating for wet or outdoor environments. |

| Lockable Type | Can be secured with a padlock or key for enhanced safety. |

Typical Application Scenarios in Industrial Equipment

Equipment Shell and Panel Fixing

Used to secure door panels of control cabinets and mechanical housings. Ensures easy maintenance and prevents unauthorized access.

Transportation and Logistics Equipment

Fixes doors of containers, trucks, and cargo boxes. High strength and vibration resistance make it ideal for mobile environments.

Medical and Laboratory Equipment

Locks enclosures in devices where sealing and hygiene are essential.

Marine & Aviation Equipment

Used in ship hatches, aircraft compartments. Offers excellent corrosion resistance and reliability in extreme conditions.

Cam Latch Advantages in Outdoor Environments

Unique Needs for Outdoor Enclosures

| Requirement | Solution |

|---|---|

| Severe Weather | Use waterproof Cam Latch with IP67 protection. |

| Corrosion Resistance | Use stainless steel or zinc alloy material for salt spray and acid rain protection. |

| Security | Choose anti-pick designs like hidden latches. |

Common Outdoor Applications

- Traffic Control Boxes: Withstand vibration and temperature fluctuations.

- Solar Control Cabinets: Require anti-UV and aging-resistant materials.

- Communication Base Stations: High IP rating needed to block dust and sand.

How to Choose the Right Cam Latch?

Choose Based on Environment

| Environment | Recommended Type |

|---|---|

| Indoor | Standard Cam Latch |

| Outdoor | Waterproof + Stainless Steel Cam Latch |

Choose Based on Frequency of Use

| Use Frequency | Operation Mode |

|---|---|

| Low | Key or tool-based opening |

| High | Knob or handle |

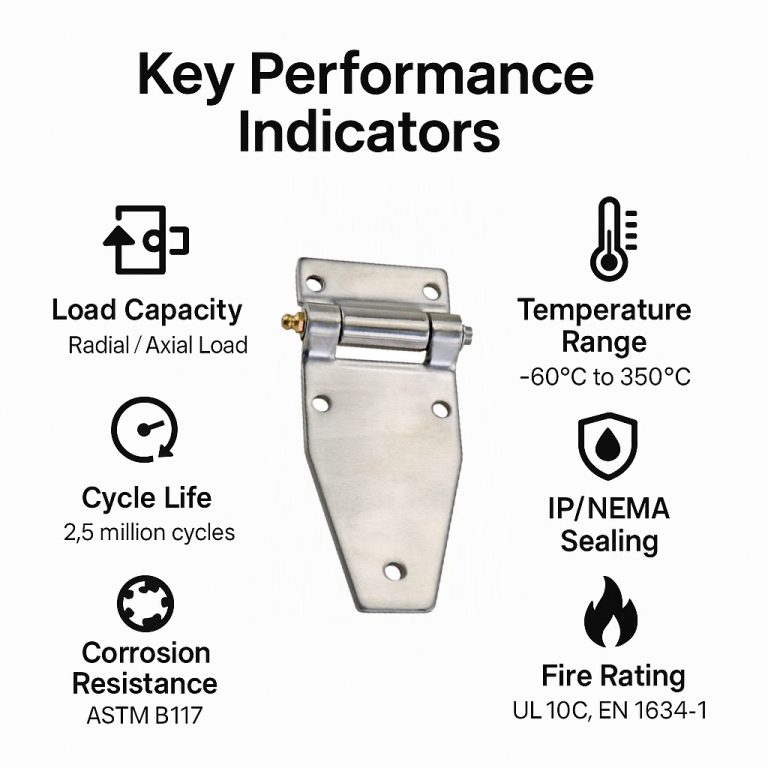

Compare Key Parameters

| Parameter | Recommendation |

|---|---|

| Installation Size | Measure panel thickness and hole diameter. |

| Protection Level | IP65 for general use; IP67 for rain-prone areas. |

| Load Strength | Longer cam = stronger load capacity. |

Purchase Suggestion

- Prefer ISO-certified brands (e.g. Southco, HTAN).

- Request samples for compatibility testing before bulk orders.

Cam Latch Installation Guide

Preparation Before Installation

- Measure panel thickness

- Prepare tools: drill, tape measure, screwdriver

Installation Steps (Standard Model)

- Mark hole position on the panel

- Drill hole (ensure it matches Cam Latch specs)

- Insert latch and fix with nut

- Test handle operation and cam movement

Common Installation Errors

| Problem | Cause | Solution |

|---|---|---|

| Loose Latch | Hole too large | Reinforce with spacers |

| Can’t Lock | Misalignment | Adjust fixing slot position |

Maintenance and Troubleshooting

Daily Maintenance

- Check flexibility of cam every quarter

- Apply lubricant if needed

- Clean surface stains

Common Problems and Fixes

| Problem | Cause | Solution |

|---|---|---|

| Stuck Latch | Dirt or worn spring | Clean or replace spring |

| Poor Sealing | Aged seal | Replace seal promptly |

Upgrade Tips

- Increased Load? → Use longer latch

- No Anti-pick Design? → Upgrade to security Cam Latch

Conclusion

Optimize the locking system of industrial equipment by selecting the right Cam Latch.

Though small, the Cam Latch significantly impacts equipment safety, reliability, and maintenance. Whether for indoor power cabinets or outdoor base stations, selecting and installing the appropriate latch model helps:

- Reduce equipment failure

- Improve maintenance efficiency

- Extend service life

Use this guide to assess your needs and consult HTAN suppliers for tailored solutions.