HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Locking technology continues to improve as the need for office security and industrial equipment protection increases.

Cam locks are simple and quick to install, making them the lock of choice for many applications.

Whether lockers, filing cabinets, electrical boxes, and other application scenarios requiring locks, they provide reliable locking functionality.

The next step is to explain the principles and types of cam locks, as well as the advantages of applying them in different scenarios.

What is a Cam Lock? Principle of Operation and Common Types

Definition and Principle of Operation

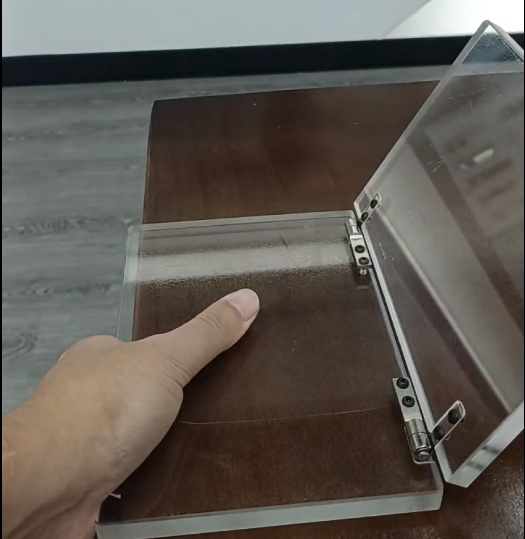

A cam lock is a locking device that achieves locking by rotating a cam blade.

When the key is inserted and rotated, the internal cam piece will follow the rotation and push the latch to complete the action of unlocking or closing.

Cam locks are commonly used on drawers, cabinet doors, equipment panels, and other equipment that needs to be opened and closed quickly.

Main Types

Cam Lock Types

- Keyed cam locks: the most basic style, controlled by a physical key to unlock the door.

- Tubular cam locks: use a cylindrical key for greater security and are commonly used in high-security scenarios.

Key Cam Lock Features: Construction, Security and Maintenance

Construction and Materials

- Body material: zinc alloy, stainless steel and brass are common choices. Stainless steel is suitable for wet environments, while zinc alloy is less costly.

- Cam shape: Flat type is suitable for short stroke locking, curved design can provide greater locking torque.

Safety Features

- Anti-pick design: Some cam locks are equipped with anti-drilling steel plates or shaped locking holes to prevent violent damage.

- Anti-corrosion treatment: Surface plating or coating can extend the life of outdoor use.

Installation and Maintenance

- Installation: Nut fixing is suitable for thicker cabinet doors, snap-in installation is faster.

- Routine maintenance: Apply lubricant every six months and check whether the nut is loose.

Application of Cam Locks on Filing Cabinets

Security Needs of File Cabinets

Office file cabinets need to store confidential documents and must be protected from being opened by unauthorized personnel.

Libraries, archives and other high-classified places have higher anti-theft requirements for locks.

Applicable Scenarios

- Steel/wooden filing cabinets: Cam locks can be directly installed in the reserved holes of the cabinet door, with strong compatibility.

- File room intensive cabinet: Support multiple cabinets interlocking, improve the overall security.

Advantage Analysis

- Convenient installation: Only need to tighten the nut after opening the hole in the cabinet door, and it can be completed within 10 minutes.

- Easy to replace: Standardized size design can replace cam locks of different brands.

Application of Cam Locks on Lockers

Locker Requirements in Public Places

Lockers in schools, gyms, stations, etc. need to be opened and closed frequently, and the locks must be durable and anti-theft.

Application Examples

- Steel lockers: Stainless steel cam locks are rust-proof and have a high load-bearing capacity.

User Experience

- Fast lock opening: Rotate 90° to open, suitable for fast-paced scenarios.

- Low-cost maintenance: Simple structure and low failure rate.

Application of Cam Locks on Electrical Boxes

Protection Requirements for Electrical Boxes

Industrial distribution boxes, outdoor control cabinets and other equipment need to meet the dust-proof, waterproof (IP54 ~ IP65 standards), while preventing the risk of electric shock caused by misuse.

Typical Application Scenarios

- Industrial cabinet panels: Compact cam locks do not take up internal space and are suitable for tight environments.

- Outdoor electrical box: Stainless steel lock body with UV coating, resistant to rain and high temperature.

Advantage Analysis

- High environmental adaptability: Corrosion-resistant material can cope with harsh environments such as chemical plants and coastal areas.

- High security: Some models with multi-point locking function to prevent the box from being pried open.

Cam Lock Selection and Installation Guide

Selection of Type According to Environment

- Office scenarios: Keyed or tubular cam locks are sufficient.

- High security scenarios: Choose an electronic cam lock or a tubular lock with an anti-drill design.

Installation Steps

- Measure the size: Confirm that the thickness of the cabinet door and the hole diameter match the lock body.

- Fixing the lock body: Insert the lock cylinder and tighten it with a nut from the inside.

- Test the function: Open and close several times to check whether it is smooth and adjust the angle of cam piece.

Maintenance Recommendations

- Quarterly: Clean the dust of the lock hole to avoid key jamming.

- Annually (for outdoor use): Check for coating peeling.

FQA

Q:What should I do if the cam lock does not rotate smoothly after a long time of use?

A:If the cam lock does not rotate smoothly, it may be due to the accumulation of dust inside the lock cylinder or insufficient lubrication, you can add lubricant.

Q:Can camlocks from different brands be replaced?

A:Most cam locks are designed with standardized dimensions. It is recommended to confirm that the length of the cylinder, the type of key and the angle of the cam are the same to ensure effective installation and use.

Q:What should I be aware of when using cam locks in outdoor environments?

A:In outdoor or humid environments, it is recommended to use cam locks made of stainless steel or cam locks with anti-corrosion coating to ensure corrosion and rust resistance.

Conclusion

Cam locks are simple in structure and easy to install, widely used in filing cabinets, lockers and electrical boxes and other related equipment.

Whether it is to protect confidential documents, enhance the security of lockers or to meet the protection needs of electrical boxes, choosing the right type of cam lock is crucial.