HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

This article explores the importance of improving refrigeration hinges in terms of durability, energy efficiency, load-bearing capacity, ease of installation and maintenance, and environmental adaptability. By prioritizing these factors, manufacturers can ensure superior performance and reduce long-term costs, ultimately improving the overall efficiency of refrigeration systems.

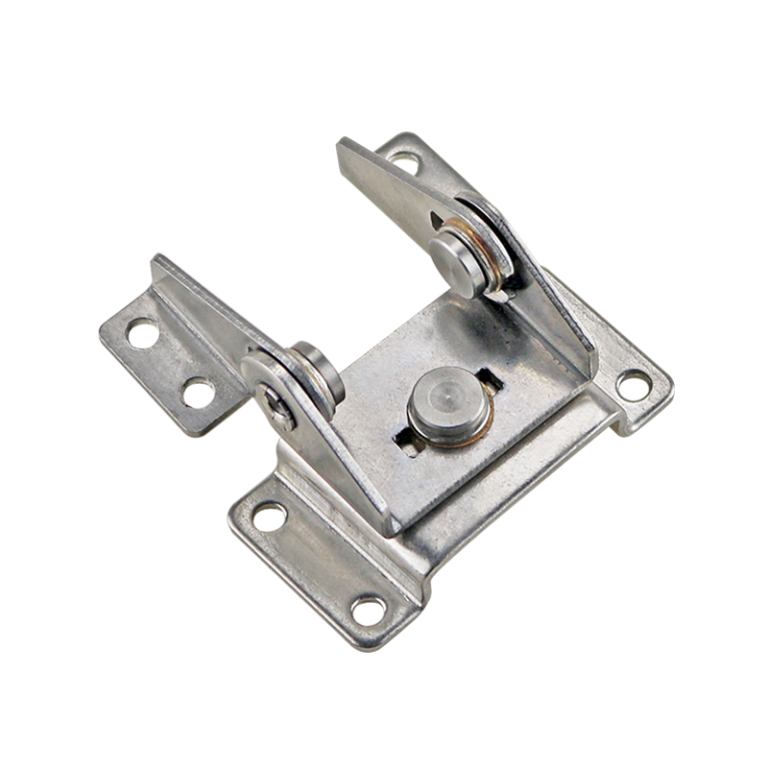

Cold Storage Door Hinges,Made from stainless steel, these hinges are heavy-duty and designed for use in industrial equipment, cold storage doors, industrial ovens, and more.

1. Enhancing Durability and Performance of Refrigeration Hinges

Refrigeration facilities rely heavily on the Refrigeration Hinge, which is a vital part in the cooling industry, acting as the foundation for maintaining their structural soundness. The Refrigeration Hinge is constructioned to specifically tolerate severe temperatures and severe conditions, thereby ensuring flawless operation in frozen environments. This article will explore the importance of improving Refrigeration Hinges and will examine the various factors that must be taken into account to guarantee their highest performance and longer life.

The primary consideration in the construction of Refrigeration Hinges is their longevity and corrosion protection. Premium materials must be used to make Refrigeration Hinges capable of tolerating the demands of cold conditions. The hinge’s longevity is of paramount importance, as it is continually subjected to moisture, severe temperatures, and possible corrosive substances.

By improving Refrigeration Hinges with superior corrosion protection, the equipment’s lifespan can be considerably increased, and service costs can be reduced.

Sturdiness and rust repulsion are the most key qualities of cold storage facilities Hinges, as they are exposed to demanding contexts. Cold storage facilities Hinges must be built from components such as inox or alu, which offer excellent repulsion to rust and can endure the severe heat/cold and humidity located in cooling warehouses.

2. Improving Energy Efficiency and Power Conservation in Cold Storage Hinges

Energy efficiency is a critical element in the cooling sector, and it is directly related to the running expenses of cooling warehouses. By improving to more energy-efficient versions of cold storage facilities Hinges, power usage can be minimized, leading to considerable savings over time.

Power conservation is a major concern for cold storage facilities, given that cooling units account for a significant portion of the total utility expenses. Over time, upgrading to more energy-efficient Chilled Storage Hinges can result in a considerable reduction.

Another factor in power conservation is the hinge’s heat passage property, which, with a lower level, can minimize heat exchange between the interior and exterior of the cold storage facility, thereby reducing the workload on the refrigeration system.

3. Maximizing Load-Bearing Capacity and Safety in Cold Storage Hinges

The carry strength of cold storage facilities Hinges is a crucial element as they carry the weight of doors and shutters in cold storage facilities contexts. Improving to cold storage facilities Hinges with increased carry strength can guarantee the secure dependability of the area, and prevent incidents and injury to machinery.

The load-bearing capacity of refrigerated storage Hinges is a key consideration because they are responsible for supporting the weight of doors and gates in refrigerated storage facilities. Transitioning to hinges with higher load-bearing capacity can ensure the safety and dependability of the establishment and avoid accidents and harm to the machinery.

When choosing refrigerated storage Hinges, it is crucial to consider both the weight of the gates and doors and their usage frequency. Hinges with a higher load-bearing capacity can accommodate larger gates and doors, thereby lessening the chance of damage and extending the life expectancy of the machinery.

4. Streamlining Installation and Maintenance of Refrigeration Hinges

Ease of assembly and upkeep is another crucial element of cold storage facilities Hinges. Changing to hinges tailored to fast and effortless assembly can save time and workforce expenses.

Both the installation and maintenance of Chilled Storage Hinges can significantly impact the equipment’s cumulative effectiveness and lifespan. Adopting hinges that are designed for speedy and easy setup can save effort and expenditure, particularly in massive initiatives.

When choosing Chilled Storage Hinges, it is crucial to consider the fitment procedure; hinges with pre-drilled openings or component-based layouts can streamline the fitment procedure and minimize the time needed for installation. Moreover, hinges that are simple to dismantle and clean can lower care work and ensure the hinge operates seamlessly throughout its lifespan.

5. Selecting the Right Refrigeration Hinges for Specific Environmental Needs

When choosing Chilled Storage Hinges, it is crucial to consider the unique surroundings of installation. For facilities with excessive moisture or exposure to corrosive substances, hinges with a higher rust resistance rating are necessary.

Ultimately, replacing refrigerated storage Hinges is crucial for achieving best functionality, energy conservation, and sturdiness in refrigerated storage units. By prioritizing sturdiness, rust resistance, energy conservation, installation simplicity and care, and load-bearing capacity, property administrators and operators can make well-informed choices that improve functioning and cut expenses.

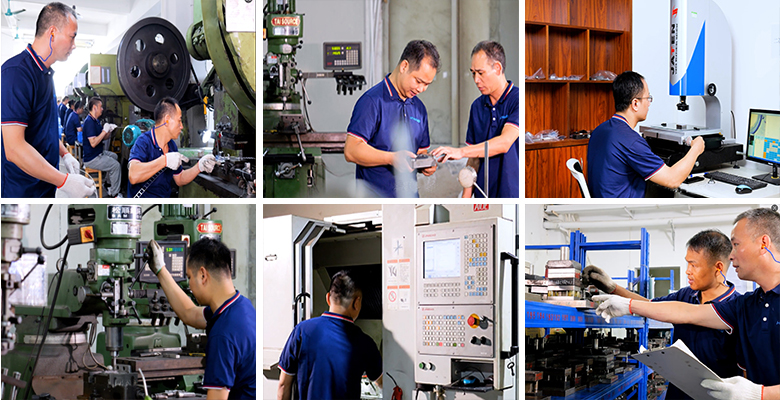

HTAN was established in 2015, specializing in the research, development, and production of industrial enclosure components. Its main products include torque hinges, handles, hinges, Latches, and other cabinet door accessories. The company employs 80 people and operates an independent factory spanning 7,000 square meters, with an integrated supply chain system that covers everything from design to sales. Its products are widely used in industries such as special vehicles, rail transportation, medical equipment, and industrial automation equipment.

Avoiding Losing Reliable Partner, Welcome To Contact HTAM

-768x768.png)