HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

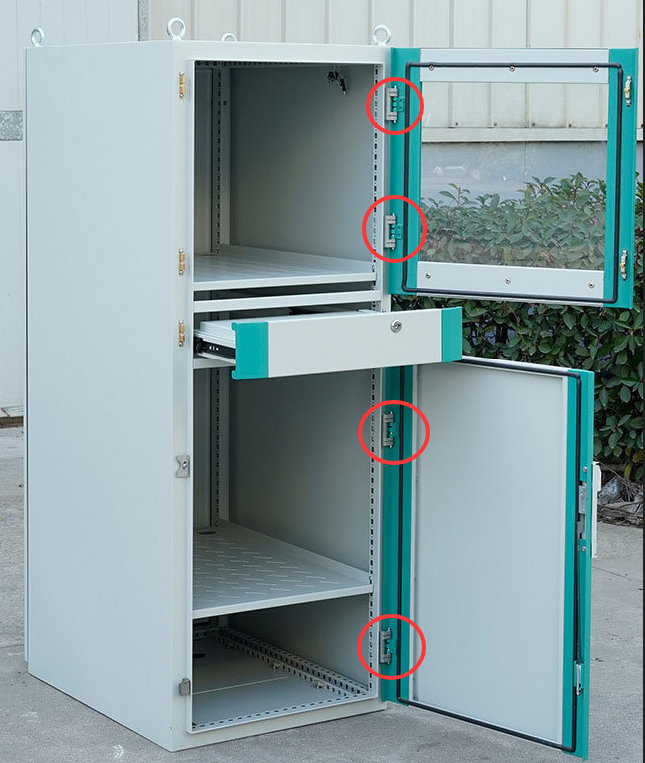

As data centers and communications infrastructures continue to demand more space and design, concealed hinges not only optimize cabinet functionality, but also significantly improve equipment safety and maintenance efficiency.

Understanding Your Network Cabinet Needs

Types and Structure of Network Cabinets

Network cabinets are mainly divided into server cabinets, wiring cabinets, wall-mounted cabinets, and other types.

Different structures of cabinets have different needs for hinges.

When choosing concealed hinges, the thickness, weight, and material of the door body must be considered.

- Metal door panels need hinges with strong load-bearing capacity.

- Glass door panels should be paired with concealed hinges with anti-vibration design.

If the hinge does not match the door panel, it may lead to deformation or poor opening and closing.

Influence of Installation Environment on Hardware Accessories

Network cabinets may be installed indoors or outdoors:

- Indoor data centers: low humidity but require frequent maintenance

- Outdoor cabinets: exposed to temperature changes, rain, and corrosive air

In high-security locations (e.g., data centers), hinges should have less exposed structure to prevent vandalism.

In edge node cabinets, maintenance convenience is more important.

The Core Advantages of Concealed Hinges

Aesthetic and Industrial Design Consistency

The most important feature of concealed hinges is their simple appearance.

- Fully embedded inside the cabinet door

- Avoid raised structure of traditional hinges

- Matches modern industrial aesthetics

- Ideal for glass doors and aluminum profiles

Enhanced Safety and Protection Level

- Fewer exposed mechanical parts reduce the risk of accidental touch or damage

- Prevent unauthorized access in public machine rooms

- Better seal for cabinet gaps

- Supports IP54 or higher protection rating against dust and liquid ingress

Installation Flexibility and Maintenance Convenience

- Many concealed hinges support quick-fit design and multiple opening directions

- Easy maintenance: only a few screws to replace

- Some models support 3D adjustment to correct installation errors and ensure door alignment

How to Choose the Concealed Hinge for Your Cabinet

Relationship Between Opening Angle and Frequency of Use

- Narrow spaces: choose hinges with opening angle < 100°

- High-frequency operations (e.g., data centers): use > 120° hinges for full door expansion

Load-Bearing Capacity is Critical for Cabinet Door Support

- Single hinge load capacity: 10–30 kg

- Heavy doors: use at least 2 hinges and reinforcement brackets

Influence of Material on Service Life

- Zinc alloy: low cost, indoor use, lasts 5–8 years

- Stainless steel: corrosion-resistant, lasts 10+ years

- Nylon composite: lightweight, for light cabinets, but poor high-temp resistance

Surface Treatment and Durability

- Electroplating: rust resistance

- Spray coating: customizable colors

- Anodizing: for aluminum hinges

- Should pass 48-hour salt spray test

Adjustable and Removable Functions

- 3D adjustment: correct ±2mm installation deviation

- Quick-release design: allows door removal without screw disassembly

- Ideal for 5G base station cabinets

Popular Brands for Concealed Hinges

Haitan (HTAN)

- High-end industrial cabinet accessories

- Precision error < 0.1mm

- Suitable for various door thicknesses

Southco

- Modular design

- Quick-replaceable parts

- Compatible with 19-inch and 23-inch racks

EMKA

- Complies with EN 1670 anti-corrosion standard

- Built-in EMC shielding

- Used in medical and military fields

Rittal

- Integrated buffer function to prevent door collision

- Used in air-cooled cabinet inner doors

FQA

Q: What kind of cabinets are suitable for concealed hinges?

A: Cabinets requiring high protection level or focusing on appearance design, such as data centers and intelligent building control cabinets.

Q: Is it complicated to install concealed hinges?

A: Most products provide pre-drilled templates, saving 30% installation time compared to traditional hinges.

Q: Will concealed hinges affect cabinet protection?

A: If installed correctly, concealed hinges increase the IP protection level by reducing cabinet gaps.

Q: How to judge the service life of concealed hinges?

A: Refer to product test reports; high-quality models can withstand 50,000+ open/close cycles.

Selecting Concealed Hinges Based on Environment

Indoor Data Center vs Outdoor Communication Cabinet

- Outdoor: must choose stainless steel with plated surface

- Indoor: zinc alloy or aluminum can be considered

High-Frequency vs Low-Frequency Opening Scenarios

- For >20 openings/day: use hinges with ball bearings

- Reduces friction by 60%, prolongs service life

Tamper-Proof / Anti-False Opening Design

- For high-security areas: select hinges with profiled screws

- Only removable with special tools to prevent unauthorized access

How to Install and Maintain the concealed Hinge Correctly

Brief Description of Installation Steps

- Align hinge holes with positioning fixture

- Fix cabinet side screws first, then door side

- Adjust eccentric screws to eliminate door gaps

- Test smoothness of opening and closing

Common Installation Mistakes

Error: Using hinges for steel doors on 2mm aluminum door panels

Correct: Measure door thickness within ±0.5mm and select the appropriate model

Regular Maintenance Recommendations

Every 6 months:

- Tighten screws to 2–3N·m using torque wrench

- Remove dust, apply silicone-based lubricant to pivot

- Check for door sag >3mm – if so, replace the hinge

Conclusion

Concealed hinges significantly improve the safety, aesthetics, and service life of network cabinets through structural optimization.

When selecting hinges, consider:

- Load-bearing capacity

- Corrosion resistance

- Installation flexibility

For high-frequency use, prioritize stainless steel hinges with buffer function.

Regular maintenance extends hinge life and reduces O&M costs.

Through reasonable selection and correct installation, concealed hinges become key support components for efficient operation of network cabinets.