HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Imagine opening a laptop screen or an industrial equipment access door. With position-control hinges (also known as torque or friction hinges), the panel holds at any angle without sagging. Conventional hinges often fail to prevent sudden panel drops or closures due to lack of built-in damping after wear, posing operational risks and maintenance costs. In contrast, position-control hinges incorporate friction mechanisms that generate controllable torque during rotation, enabling panels to “hold” at any angle. This feature eliminates the risk of uncontrolled collapses, significantly enhancing equipment safety and reliability.

Industry Pain Point: In industrial settings, heavy covers or panels require manual support to prevent sudden gravitational collapse. Operators must use both hands to hold panels during maintenance, reducing efficiency and increasing pinch risk.

Key Advantages: Position-control hinges provide precise motion control, stabilizing panels at desired angles without requiring additional springs, cylinders, or dampers. They effectively prevent covers from snapping back or slamming shut, reducing collision and pinching incidents.

This article explains how position-control hinges function, their industrial applications, and how to select the appropriate model based on panel weight and required torque. First, we must understand their fundamental difference from traditional hinges.

What is a Position-Control Hinge?

Position-control hinges (also known as friction or torque hinges) feature a specialized design incorporating friction mechanisms. Its primary function is to stabilize door panels or covers at any open angle, unlike standard hinges that only allow free swinging or passive closing. This design generates internal friction as the door panel rotates, automatically “locking” it in place.

Naming conventions

Due to differing internal mechanisms, position-control hinges are also called torque hinges or friction hinges. These terms are often used interchangeably in literature; the term “torque hinge” emphasizes the resistance generated by friction plates.

Differences from standard hinges

Standard hinges (such as door hinges) merely provide a pivot point for door panels and lack self-positioning capabilities. They require external supports or limiters to secure the door panel’s position. Position-control hinges, however, integrate friction pads, springs, and other components internally. These generate resistance during rotation, allowing the door panel to be held at any angle. Adjustable torque hinges further permit friction force adjustment via preload screws, achieving damping effects matched to the panel’s weight.

Typical Application Scenarios

Position-control hinges are widely used in applications requiring stable positioning. For instance, laptop and monitor screens commonly use them to allow the screen to stay open at any angle. Control panels and access doors on industrial equipment can also utilize these hinges to remain open. Medical devices (such as monitor mounts and inspection hatches) require precise positioning. Vehicle doors and displays frequently employ torque hinges. They simplify designs, eliminating the need for additional support components while maintaining safety.

How Torque Hinges Work — “Controlled Friction Torque”

The key to position-control hinges achieving free suspension lies in their internal friction mechanism. Specifically, the hinge consists of a fixed blade and a rotating blade, with a set of friction washers or discs (typically a combination of stainless steel and engineering plastics) sandwiched between them. These friction elements are compressed by a preload nut or adjustment screw. This generates the desired rotational resistance.

Core Mechanism

When the panel is pushed, its rotational torque causes relative movement between the friction surfaces inside the hinge, generating a friction torque. This friction torque is proportional to the panel’s weight, counteracting the rotational force caused by gravity to keep the panel stationary at any angle. For example, when a user releases a laptop screen, it stays in position instead of dropping—thanks to the friction mechanism inside the hinge.mechanism at work.

Torque Calculation

To select an appropriate torque hinge, first calculate the required torque. Torque is typically measured in Newton-meters (N·m) or pound-feet (lbf·in) and calculated using the formula T = F × d. Here, F represents the applied force (usually the gravitational force from the panel’s weight), and d is the distance from the panel’s center of gravity to the hinge axis. For example, a 15 kg panel exerts a gravitational force of ≈147 N (15 kg × 9.8 m/s²) at a center of gravity 0.3 m from the hinge axis, requiring ≈44.1 N·m torque.. Actual designs must also account for installation angles and safety margins.

Internal Structure

A typical torque hinge contains: a fixed hinge blade, a connected movable blade, a set of friction discs/washers, and a preload nut (or rivet) mechanism. Friction discs are typically composed of high-hardness stainless steel and wear-resistant polymer layers. Tightening the nut applies preload, altering the contact pressure between friction pairs. Adjustable hinges incorporate internal screws to further modulate friction force, accommodating varying load requirements.

Through this structural design, position-control hinges generate controllable torque internally. When a panel opens or closes on the hinge, the rotational force is immediately “sensed” by the internal friction mechanism, which automatically provides corresponding resistance to hold the panel at its current angle.

The Importance of Position-control hinges

Position-control hinges deliver multiple benefits to industrial and consumer products, particularly in safety, efficiency, and durability:

Safety

Torque hinges are made with wear-resistant materials, such as stainless steel and engineering plastics, on internal friction surfaces, giving them a design life of tens of thousands of cycles. High-quality models maintain stable performance through 50,000–100,000 cycles. With normal use and routine maintenance, friction wear remains minimal, and the hinges often outlast other components in the equipment.

Efficiency Enhancement

With torque hinges, panels can be adjusted and held in position with one hand, freeing the other for assembly or maintenance tasks. These hinges allow door panels to remain at any angle without requiring additional support rods or stops, simplifying equipment design. Users no longer need to strain to find support points, and the entire opening/closing process becomes smooth and effortless, significantly boosting work efficiency.

Durability

High-quality torque hinges use wear-resistant materials such as stainless steel shafts and engineering plastics. They can withstand prolonged cyclic use. Typical product lifespans exceed tens of thousands of cycles (some models surpass 100,000 cycles), far surpassing conventional hinges in durability. Additionally, their design eliminates the need for external lubrication or maintenance of auxiliary components, reducing long-term upkeep costs. Internal friction components remain unaffected by external environments (no exposed metal springs), ensuring consistent performance even after repeated cycles.

Streamlined Design

Torque hinges assume the function of panel support, eliminating the need for additional support arms or gas springs. This not only saves space but also creates a cleaner internal structure. For instance, using torque hinges in cabinet doors or enclosures eliminates the need for cumbersome support struts, increasing internal usable space.

In summary, position-control hinges achieve precise control of opening and closing motions through built-in friction torque, offering significant safety and efficiency advantages. Having understood these benefits, we proceed to the next step: selecting the appropriate torque hinge based on specific requirements.

Types of Position-control hinges

| Type | Typical Applications | Features |

|---|---|---|

| Constant Torque Hinge | Laptop displays, industrial equipment access doors, etc. | Consistent torque throughout the entire range of motion, enabling smooth positioning at any angle. Ideal for applications requiring seamless, arbitrary angle positioning. |

| Dual-axis torque hinge | Medical instrument arms, multi-axis monitor mounts, etc. | Features two rotational axes generating torque in both directions, enabling more complex positioning actions. For example, some models support both rotation and tilt functions simultaneously. |

| One-way control hinge | Electrical cabinet doors, maintenance access panels, etc. | Friction activates in one direction only. Allows free movement in the open/lift direction while providing damping in the opposite direction, enabling secure locking only in the specified direction. Suitable for applications requiring unidirectional locking. |

| Adjustable Torque Hinge | Modular equipment panels, industrial cabinet doors, etc. | Features an internal adjustment screw to modify friction torque during installation, accommodating varying panel weights. Torque can be precisely calibrated to suit diverse load requirements. |

Selecting the right torque hinge involves matching torque to application scenarios, not just size. For instance, if supporting heavy door panels, a fixed-torque hinge may lack sufficient holding force; an adjustable torque hinge can achieve the required torque through post-installation adjustment. The next section details how to select hinges based on torque requirements, panel specifications, and environmental conditions.

How to Select the Right Hinge

Key Parameters

When choosing hinges, prioritize required torque, panel dimensions/weight, and opening angle. Calculate torque requirements based on object weight and center of gravity (using formula: Torque = T = F × d, where F = panel weight × gravitational acceleration, and d = horizontal distance from center of gravity to hinge axis). For example, a 10kg panel with a center of gravity 0.2m from the hinge axis requires ≈10 kg × 9.8m/s² × 0.2m ≈ 19.6 N·m of torque. Select a hinge with a rated torque slightly exceeding this value. If the hinge torque is too low, the panel will sag; while excessive torque will make operation difficult.

Panel Size and Weight

Larger and heavier panels generate greater torque; panel shape also affects the center of gravity. Common recommendations: Lightweight panels (<5 kg) can use small hinges, while large panels (>15 kg) require high-torque hinges or multiple hinge combinations. Also consider the panel opening angle (90°, 120°, 180°, etc.), as hinge resistance distribution varies at different angles. For 90° opening only, standard torque hinges suffice; for 180° or wider angles, verify the hinge supports the full opening range with sufficient torque margin.

Material Selection

Choose hinge materials based on environmental requirements. Stainless steel hinges offer strong corrosion resistance (commonly AISI 304/316), suitable for medical devices, marine, and chemical environments, meeting ISO 9227 salt spray test requirements. Aluminum alloy hinges are lightweight, ideal for portable or aerospace equipment, typically anodized for corrosion resistance. Zinc alloy/galvanized steel hinges offer low cost for general industrial applications, though rust-proof coatings must be applied. Material selection must also comply with relevant standards (e.g., RoHS 3.0 Directive, ISO 9001/ISO 13485 quality systems) to ensure quality and safety.

Environmental Factors

Products meeting corresponding test standards must be selected for special environments. For instance, in high-vibration scenarios, verify hinge strength using IEC 60068-2-6 (vibration testing) or IEC 60068-2-27 (shock testing). In extreme temperature conditions, consider high/low-temperature testing per GB/T 2423 or the IEC 60068 series. For chemical corrosion risks, select surfaces treated to pass ASTM B117/GB/T 10125 salt spray testing. For dust and water resistance, choose sealed hinges meeting IEC 60529 protection ratings.

Proper selection requires integrating these factors: panel weight, opening angle, and operating environment. It is recommended to carefully calculate torque requirements and consult technical specifications before purchasing to ensure the selected hinge can support the load and operate stably under actual working conditions.

Industrial Application Examples

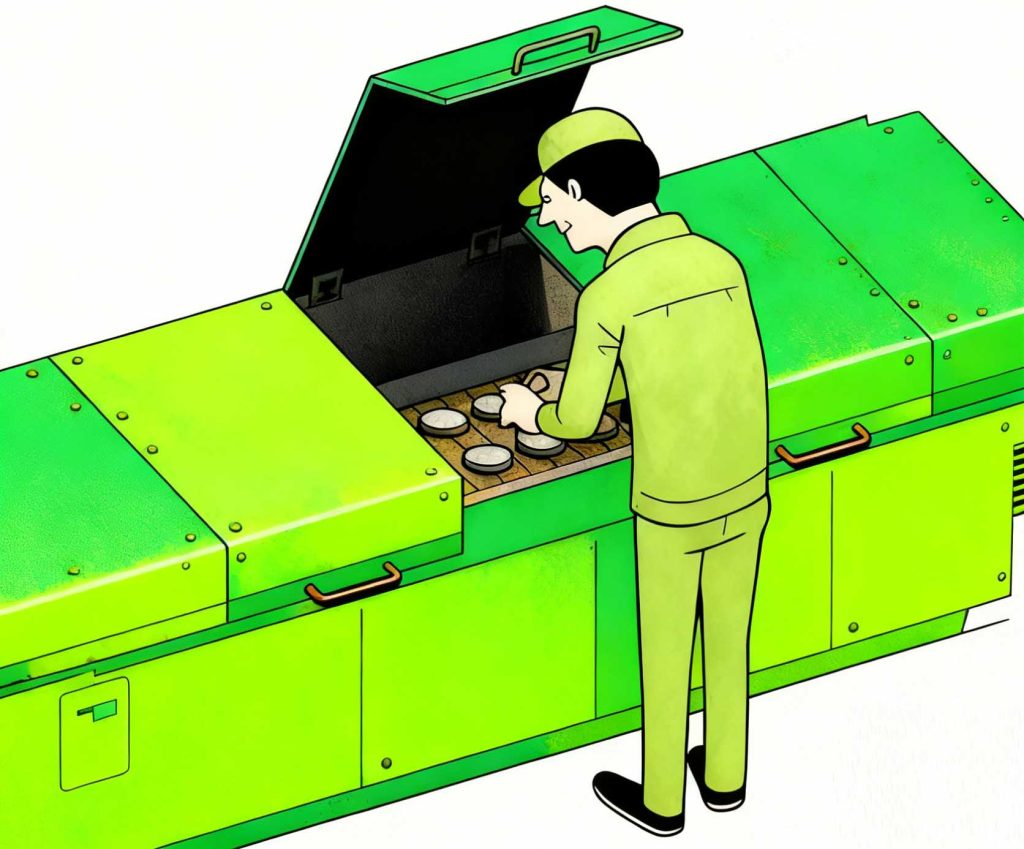

Industrial Control Panels

Position-control hinges are commonly used on production equipment and switchgear panels. During maintenance or debugging, the hinge can secure the cabinet door at the desired angle, allowing technicians to work without holding the cover. These hinges eliminate the risk of panels falling unexpectedly, enhancing operational safety.

Medical Equipment

Torque hinges are widely used on access panels or display mounts for hospital beds, operating tables, and monitoring instruments. For instance, medical monitor arms require stable positioning at various angles. Torque hinges allow doctors to adjust and secure displays with one hand, significantly improving usability.

Electronics & Consumer Products

Torque hinges are frequently used in laptop screens, flat-panel displays, and adjustable stands. They enable screens to hold at any angle without wobbling, greatly improving user experience. Additionally, flip-up doors on all-in-one computers and display cabinets often feature torque hinges for smooth opening and closing.

Transportation Equipment

The transportation sector also makes extensive use of position-control hinges, with applications including aircraft cabins, train seat entertainment screens, and instrument panels in buses and automobiles. In these high-vibration environments, they securely hold panels in place to prevent accidental closure during takeoff or driving. Simultaneously, their compact design avoids occupying extra space.

These examples demonstrate that position-control hinges provide reliable positioning and safety assurance for panel operation across diverse applications—from machine tool control cabinets and medical instruments to consumer electronics and transportation vehicles. When designing a project or selecting hinges, consider both design requirements and spatial constraints. This ensures correct hinge placement and quantity.

Installation and Maintenance Guidelines

Hinge Positioning

Determine hinge installation locations and quantities according to design specifications. Typically position hinges near the panel’s center of gravity or symmetrically for optimal balance. During installation, ensure hinge axes are parallel to panel edges, and secure mounting bolts fully.

Torque Verification

After installation, use a torque wrench or torque sensor to verify actual hinge resistance meets specifications. For adjustable hinges, modify the initial torque by tightening or loosening the adjustment screw. Ensure the actual required torque is slightly below the hinge’s maximum rated torque. Otherwise, the panel may fail to hold its position or the hinge may suffer premature damage.

Fastening Precautions

Apply moderate force when tightening hinge bolts. Over-tightening can damage preload components, while under-tightening may cause vibration or even detachment.Therefore, strictly adhere to the manufacturer’s recommended torque values during installation.

Regular Inspection

During routine maintenance, periodically inspect hinges for signs of loosening, corrosion, or abnormal wear. For frequently used equipment, inspection is recommended at least once every 3,000–5,000 cycles. If loose bolts or surface rust are detected, promptly tighten or replace the hinge. High-quality hinges generally require no additional lubrication, thanks to self-lubricating friction surfaces. However, in extreme environments, a corrosion-resistant lubricant can be applied sparingly.

Proper installation and maintenance ensure position-retaining hinges perform optimally in practical use, preventing performance degradation caused by improper installation.

Summary

Position-control hinges utilize an internal friction mechanism to achieve stable positioning of door panels at any angle, delivering safety, precision, and efficiency advantages for industrial equipment. Compared to traditional hinges, they lock panel positions without requiring additional supports or gas springs, thereby simplifying design and enhancing user experience. When selecting hinges, accurately calculate panel weight and required torque. Refer to quality systems like ISO 9001 and ISO 13485, along with relevant standards such as RoHS and ASTM B117, to ensure product quality and compliance. Selecting hinges with suitable materials and protection ratings for specific environments (e.g., vibration, temperature, chemical exposure) enhances long-term equipment reliability.

Action Recommendation

Immediately evaluate your panel parameters (weight, dimensions, opening angle) and environmental requirements. Consult with professional suppliers to determine torque needs. Select the appropriate torque hinge type based on load calculation results to substantially enhance equipment safety and user experience. Pay attention to hinge certification and testing standards (e.g., IP protection, corrosion resistance testing) to ensure selected products meet actual operating conditions. Before beginning design work, always confirm panel weight and torque requirements. Carefully select the most suitable positioning hinge to establish a foundation for long-term safe and stable project operation.

FAQ

Q: Do torque hinges wear out?

A: High-quality torque hinges incorporate wear-resistant materials, such as stainless steel and engineering plastics, on internal friction surfaces, providing a design life of tens of thousands of cycles. They typically maintain stable performance through 50,000–100,000 cycles. With proper use and routine maintenance, friction wear remains minimal, and the hinges often outlast other equipment components.

Q: Can torque be adjusted after installation?

A: For adjustable hinges, built-in adjustment screws allow friction torque to be increased or decreased at any time to accommodate new load conditions. However, fixed-torque hinges have their resistance set during manufacturing and generally cannot alter torque parameters afterward. Please confirm whether the selected model supports torque adjustment before purchase.

Q: How do torque hinges differ from gas springs?

A: Torque hinges utilize internal friction torque to hold positions without requiring an external power source, while gas springs rely on pressurized gas to support door panels. Torque hinges feature a compact design with no explosion risk or leakage concerns, eliminating the need for periodic gas refills. They are better suited for confined spaces or high-safety-requirement applications. While both serve overlapping functions, torque hinges offer simpler, maintenance-free operation ideal for designs requiring precise angular positioning, whereas gas springs excel in scenarios demanding continuous weight support.

Q: What is the service life of a torque hinge?

A: High-quality torque hinges undergo rigorous lifespan testing, with typical rated lifespans reaching tens of thousands or even hundreds of thousands of opening/closing cycles. Actual lifespan depends on usage frequency and environment, but generally far exceeds that of standard hinges. When selecting a model, refer to the cycle life parameters in the product specifications and plan maintenance cycles based on the application scenario.

Q: Do hinges require regular lubrication?

A: Most torque hinges feature self-lubricating friction plates, enabling long-term operation without additional lubrication. As long as hinges remain clean and free of debris, routine maintenance lubrication is generally unnecessary during normal use. In corrosive or extreme environments, apply rust-preventive lubricant to the hinge exterior as needed and periodically clean surrounding dust.

Q: How do I replace standard hinges?

A: Position-retaining hinges often share compatible mounting hole spacing and profiles with traditional hinges, but direct dimensional replacement is not permissible. Selection must match the hinge torque rating and panel load capacity to ensure proper functionality. When replacing, verify the new hinge’s mounting parameters and torque rating, then recalibrate the position as required. If only seeking structural replacement, ensure selection of the appropriate model or consult a professional engineer.

The above information aims to help engineers quickly grasp key usage and maintenance points for torque hinges. For further questions, consult the hinge supplier or refer to relevant industry standards and technical documentation.

-768x768-1.png)