HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In industrial environments, cabinet doors are frequently opened and closed. Push-to-open latches are a popular mechanism for this purpose.

Pressing the latch retracts it, freeing the door to open. Upon release, it springs back automatically and latches onto the door frame’s strike plate.

This entire process is quick, simple, and efficient.

Basic Structure of Push-to-Open Latches

Components of Push-to-Open Latches

Panel (housing)

This is the visible part mounted on the cabinet door, where the operating buttons are located. It not only protects the internal mechanism but also defines the latch’s external appearance and affects installation compatibility.

Pushbutton Mechanism

This is the core operating part. When the button is pressed, it actuates an internal linkage or bevel that overcomes the spring force and pulls the latch back. When the button is released, the spring force resets the button and pushes the latch out. The quality of this spring directly affects the feel and longevity of a pushbutton latch.

Latching Device

Usually a metal tongue or ball. When the latches is closed, it pops out and snaps into the locking seat fixed to the door frame to achieve locking. Some pushbutton latches use a hooked latch to provide greater holding power.

Mounting Base or Latch

This is the metal part that is secured to the cabinet door frame. This is where the latch or shackle snaps into place for locking. It must be positioned in exact alignment with the latches body.

Auxiliary Parts

These small parts are important. For example: Seal: Used for waterproof and dustproof pushbutton latches to ensure protection class (e.g. IP65/IP67). Dust cap: Covers the mounting screw holes for improved protection and aesthetics. Washers/cushions: Reduce vibration and noise, protect the cabinet panel.

Key Materials of the push-to-open latches

Common Materials

Stainless Steel (304 / 316)

304 is widely used for its excellent corrosion resistance. 316 includes molybdenum and is suited for highly corrosive environments (e.g. coastal, chemical, food plants). Longer life but higher cost.

Zinc Alloy

Die-cast molded and cost-effective. Surface treatments allow for various colors. Not as strong or corrosion-resistant as stainless steel. Suitable for indoor cabinets with budget limits.

Aluminum Alloy

Very lightweight. Suitable for mobile or weight-sensitive applications. Often anodized for corrosion resistance.

Thermoplastic Rubber (TPE) / Silicone Rubber

Used for seals and cushions. Good elasticity and aging resistance. Key to waterproof and dustproof performance.

Common Types of Push-to-Open Latches

Classification by Function

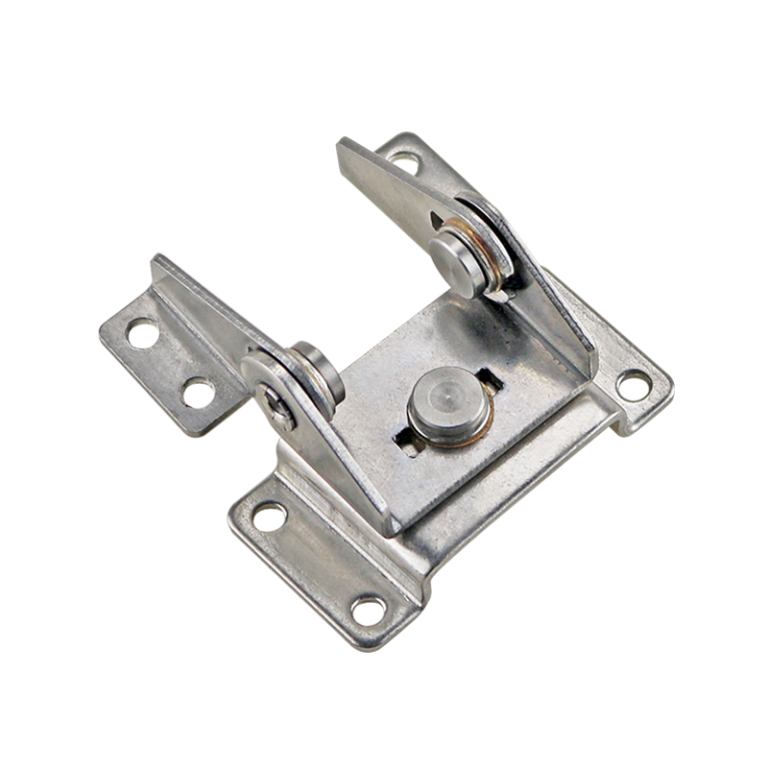

Bouncing latch

Basic type. Press to open, release to latch.

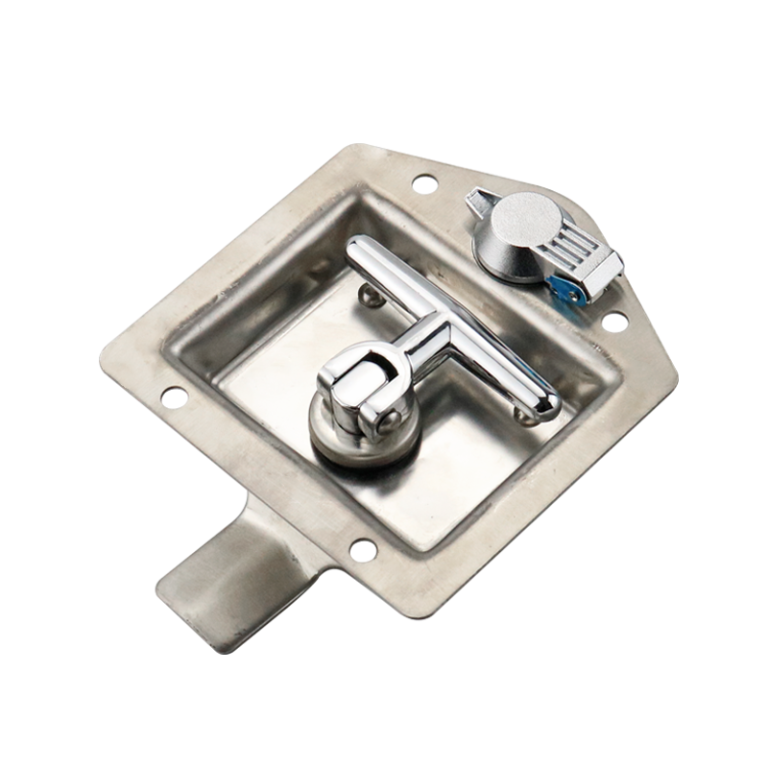

quarter-turn Latch

Mechanical locking devices for cabinet doors, equipment doors or control panels

Waterproof and Dustproof (IP65 / IP67)

For outdoor or cleanroom environments. Sealed design, stainless steel construction for durability.

Classification by Installation Method

Panel Embedded Installation

Requires a cutout in the panel. Installed from the outside and fixed from the inside.

External Surface Mounting

Attached to the outer panel surface with screws. No large hole required. Suitable for thin panels.

Hidden Installation

Fully mounted inside the panel. Minimal appearance and high security, but harder to install or maintain.

Application Scenarios and Industry Requirements

Typical Use Cases

Industrial Control Cabinets (PLC, Inverter Cabinets)

For frequent access by engineers. One-handed operation improves efficiency.

Communication Cabinets / Server Cabinets

For rapid maintenance in data centers and base stations.

Medical Equipment Enclosures

For quick sterilization, consumable replacement, or basic maintenance.

Outdoor Power Boxes (Distribution, Control Boxes)

Must withstand sun, rain, and dust. High protection grade is essential.

Selection of Key Factors

Selection Considerations

Match the Mounting Hole Size with the Panel Thickness

Ensure compatibility. Incorrect sizing can lead to installation failure or loose locks.

Frequency of Use and Life Requirements

High-use scenarios require long-life push locks.

Protection Level (IP, Corrosion)

IP65/IP67 for outdoor, dusty, humid. IP40 for dry clean rooms. 316 stainless steel for highly corrosive environments.

Locking / Key Management Features

Choose latches with cylinders if restricted access is needed. Consider your key system.

Preferred Mode of Operation

Ensure one-handed or specific operation is supported.

Matching Component Compatibility

Housing: Must match latch type and frame structure. Seals: Fit tightly with no gaps. Panel Strength: Must support repeated pressing without deformation.

Installation and Maintenance Key Points

Installation Precautions

Accurate Opening

Follow lock installation drawings. Clean hole burrs.

Align the latches Seat

Ensure the latch and latch seat are perfectly aligned.

Avoid Assembly Stress

Tighten screws diagonally and evenly to avoid distortion.

Check the Action

Test opening and closing to ensure smooth operation.

Regular Lubrication and Cleaning Recommendations

Lubricate

Light lubricant on spring and moving parts.

Cleaning

Dry cloth for dust and oil. Damp cloth in dirty environments, followed by drying. Avoid strong chemical cleaners.

Common Troubleshooting and Replacement Guidelines

Pressing Effort / Stuck

Clean or lubricate. Check for internal damage.

Latch Does Not Eject / Weak Return

Check and replace spring if needed.

Door Cannot Close / Pops Open

Inspect latch and seat alignment. Replace worn parts.

Water Ingress Issues in Waterproof Latches

Inspect seals. Replace or reinstall as needed.

Replacement

Record specifications and choose a compatible model.

Conclusion

The industrial push-button door latch is an integral part of modern industrial cabinets. It provides fast, one-handed door opening, significantly improving operational and maintenance efficiency. From rugged stainless steel to IP67-grade seals, from simple bounce designs to security-focused cylinder latch, the diversity of pushbutton door latch ensures they serve a wide range of needs: Industrial control cabinets, Communication cabinets, Outdoor power boxes, Medical equipment, Rail transit systems. Proper selection, installation, and maintenance ensure optimal long-term performance in any industrial environment.