HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Cold storage hinges are special hinge devices designed for cold storage doors, freezer doors, refrigerated containers, and walk-in freezers. In low-temperature environments, these hinges must not only bear the weight of the door but also ensure sealing performance, corrosion resistance, and long-term stability.

This article provides a comprehensive analysis of cold storage hinges in terms of definition, function, key features, applications, and selection tips to help users understand their importance and how to choose them effectively.

Definition and Function of Cold Storage Hinges

What is a Cold Storage Hinge?

A cold storage hinge is a type of metal connector specifically designed for low-temperature environments, typically installed between the cold storage door frame and the door panel.

Its main functions include:

- Supporting the weight of the door body

- Allowing the door to open and close flexibly

- Working with sealing strips to block heat and cold exchange

- Helping to maintain stable temperature inside the storage

Importance in Cold Storage Door Systems

- Structural Support: Cold storage doors are generally thick and heavy. Hinges need to withstand long-term loads of 20kg to 100kg.

- Seal Guarantee: Precision fit between hinge and door frame helps reduce cold air leakage, directly affecting energy efficiency.

Core Features of Cold Storage Hinges

High Strength and Load-Bearing Capacity

Made with thickened steel plates and multi-point bearing structures, some models can support over 100kg of door weight.

Low Temperature Resistance

Passed low-temperature impact tests, ensuring flexible rotation even in sub-zero environments.

Corrosion Resistance

Made of 316 stainless steel or nickel-plated alloy, and tested via salt spray testing, ideal for humid and cold chain environments.

Advantages of Cold Storage Hinges

Enhanced Door Sealing

Precision design between hinge shafts and sealing strips helps reduce cold storage energy consumption by 15%–20%.

Extended Service Life

High-quality cold storage hinges can last over 5 years, with more than 50,000 open-close cycles.

Easy Maintenance

Modular design supports partial replacement without disassembling the entire door.

Wide Temperature Range Adaptability

Can be applied in various environments such as:

- Food cold storage

- Pharmaceutical ultra-low temperature storage

- Cold chain logistics vehicles

Application Scenarios of Cold Storage Hinges

- Cold Storage Doors – The primary application area

- Cold Cabinet Doors – Used in cold cabinets, commercial freezers

- Low-Temperature Equipment Maintenance Doors – For large refrigeration/air conditioning units

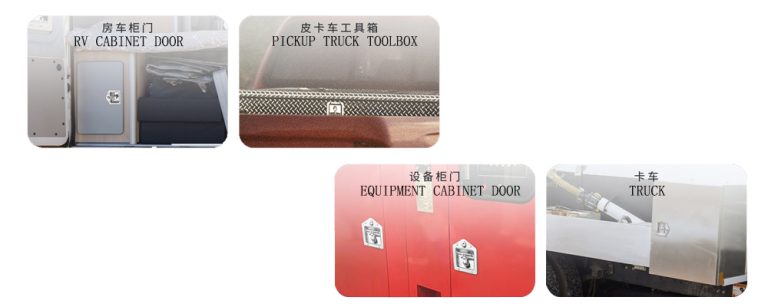

- Cold Chain Transportation Vehicles – Refrigerated trucks, freezer trucks, etc.

Cold Storage Hinges vs Ordinary Hinges: Performance Comparison

Choosing the right hinge directly impacts safety, energy efficiency, and durability. Below is a performance comparison of cold storage hinges and ordinary hinges:

Low-Temperature Adaptability

| Comparison | Cold Storage Hinges | Ordinary Hinges |

|---|---|---|

| Temperature Range | -20℃ to -50℃ | Brittle below -10℃ |

| Materials | Low-temp toughened 316 steel | Standard steel |

| Features | Anti-freezing bearings | Grease condenses, risk of breakage |

| Durability | 10,000+ cycles under low temp | 400% higher failure rate at -15℃ |

Anti-Corrosive Performance

| Comparison | Cold Storage Hinges | Ordinary Hinges |

|---|---|---|

| Material | 316L medical-grade stainless steel | 304 or carbon steel |

| Coating | Galvanized + epoxy + passivation | Basic electroplating |

| Salt Spray Test | 2,000 hours | <500 hours |

| Resistance | Humid/ammonia environments | Susceptible to intergranular corrosion |

Load Strength

| Comparison | Cold Storage Hinges | Ordinary Hinges |

|---|---|---|

| Load Capacity | ≥100kg/group | 20–50kg/group |

| Structure | Reinforced bearings | Zinc alloy, prone to deformation |

| Durability | 100,000 fatigue cycles | 35% wear after 10,000 cycles |

Cold Storage Hinge Selection Guide

When selecting a cold storage hinge, consider the following:

- Material: Prefer 316 stainless steel

- Load Capacity: Should be at least 1.5x the door weight

- Temperature Resistance: Must perform at -20℃ or below

- Installation: Choose bolted connection types

- Certification: Look for manufacturers with ISO 9001 standards

FAQs

Q1: Do cold storage hinges require regular maintenance?

A: Yes. Check lubrication every 6 months, and perform full maintenance yearly.

Q2: What is the standard cold storage door thickness?

A: Suitable for 80–200mm insulation, special models customizable.

Q3: What materials are commonly used?

A: 304 stainless steel, 316 stainless steel, and nickel-plated steel.

Q4: Are special tools needed for installation?

A: A torque wrench is required to ensure uniform force.

Q5: How long do cold storage hinges last?

A: More than 5 years indoors; depends on the usage environment elsewhere.

Conclusion

Cold storage hinges play a vital role in low-temperature environments. Their performance directly impacts sealing efficiency, energy costs, and equipment lifespan.

When selecting a hinge, always prioritize:

- Certified materials

- Verified load-bearing tests

- Compatibility with actual working conditions

A high-quality cold storage hinge ensures stable and efficient operation for your cold storage system in the long run.