HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

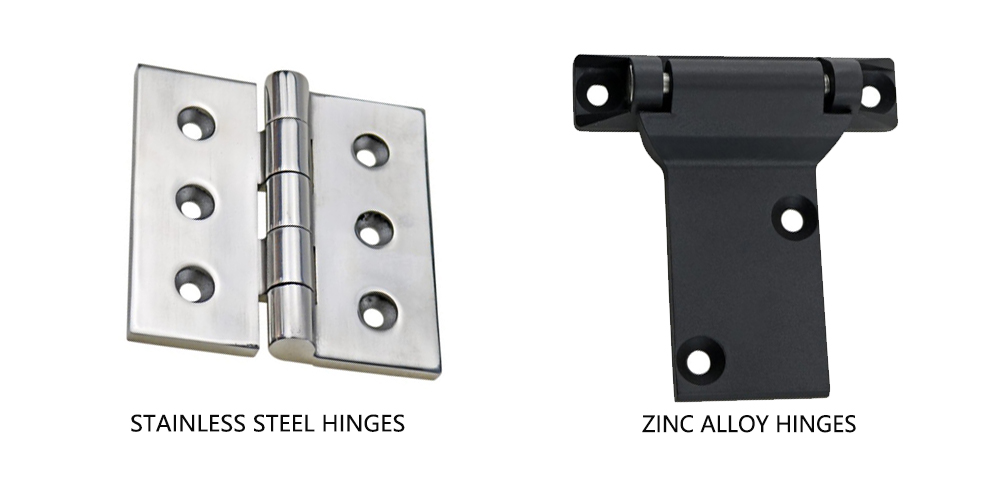

In cabinet equipment and industrial facilities, hinges are critical components that connect door panels to enclosures, ensuring smooth operation and structural integrity. They must withstand frequent use and load stress; otherwise, they risk causing frame loosening, seal failure, or even operational failures. Common hinge materials primarily include zinc alloy and stainless steel, each with distinct advantages and limitations. Zinc alloy hinges offer lower costs and ease of mass production, while stainless steel variants provide superior strength, corrosion resistance, and longevity. Understanding these fundamental differences helps businesses balance cost, performance, and durability.

Zinc Alloy vs. Stainless Steel Hinges

Zinc Alloy Hinges

- Material: Primarily zinc. Often alloyed with aluminum, magnesium, copper (e.g., ZAMAK 3, ZAMAK 5).

| Element | Common Content Range | Main Role |

|---|---|---|

| Aluminum (Al) | 3%-27% | Improve strength, hardness and heat resistance, improve fluidity. |

| Copper (Cu) | 0.5%-3% | Enhances strength and wear resistance, but high copper reduces ductility. |

| Magnesium (Mg) | 0.02%-0.06% | Trace strengthening, grain refinement, improve overall performance |

| Nickel (Ni) | 0.06%-0.10% | Enhanced corrosion resistance and high temperature stability (mainly in Zamak 7) |

| Tin (Sn), iron (Fe), manganese (Mn) | Trace | Adjustment of castability to control the influence of impurities |

Common Elements in Zinc Alloys and Their Functions

- Manufacturing: Typically made using high-pressure die casting. This allows rapid production (seconds) of complex shapes. Ideal for high-volume runs.

- Types: Common types include die-cast hinges and concealed hinges. Widely used in furniture and internal cabinet components.

- Surface Finish: Often plated (chrome, nickel) or powder-coated. This enhances appearance and boosts corrosion resistance.

- Weight: Zinc alloy has low density (~7.2 g/cm³). Resulting hinges are lightweight. Easier to install. Ideal for weight-sensitive applications.

Stainless Steel Hinges

- Material: Iron-based stainless steel. Common grades are 304 (18-8 stainless) and 316.comprehensive stainless steel guide

| Element | Content range (mass percent) | Role |

|---|---|---|

| Chromium (Cr) | 18.0% – 20.0% | Formation of a protective layer of chromium oxide, providing corrosion resistance |

| Nickel (Ni) | 8.0% – 10.5% | Stabilizes austenite structure, enhances ductility, high temperature performance and corrosion resistance |

| Carbon (C) | ≤ 0.08% | Low carbon reduces carbide precipitation and improves weldability (304L: ≤ 0.03%; 304H: ≥ 0.04%) |

| Manganese (Mn) | ≤ 2.0% | Improve strength and work hardening ability |

| Silicon (Si) | ≤ 1.0% | Enhance oxidation resistance and high temperature strength |

| Phosphorus (P) | ≤ 0.045% | Impurity elements, need to be strictly controlled to maintain the toughness of materials |

| Sulfur (S) | ≤ 0.030% | Impurity elements, excess will reduce corrosion resistance and processing performance |

| Iron (Fe) | balance | as the base metal, constitute the main body of the alloy |

| Nitrogen (N) | ≤ 0.10% (trace) | may be present in small amounts, not the main added elements |

| Molybdenum (Mo) | Usually not present | Molybdenum-containing version is 316 stainless steel (higher corrosion resistance) |

Ratio of major elements (mass percent)

- Properties: 304 offers good mechanical properties and corrosion resistance (18% Cr, 8% Ni). 316 adds molybdenum. This significantly improves resistance to salt, acids, and chemicals.

- Manufacturing: Made via stamping, bending, welding, or casting. More diverse processes than zinc alloy.

- Surface Finish: Typically natural polished or brushed. No additional plating needed for long-term rust resistance. Highly scratch-resistant. Retains appearance over time.

- Weight & Cost: Material is heavier than zinc alloy. Single hinges can be 20-30% heavier. This increases shipping and installation complexity. Stainless steel is also more expensive.

- Initial Choice: Zinc alloy often suits cost-sensitive indoor cabinets or furniture. Stainless steel is preferred for outdoor cabinets, heavy loads, or chemical environments.

Material Properties Comparison

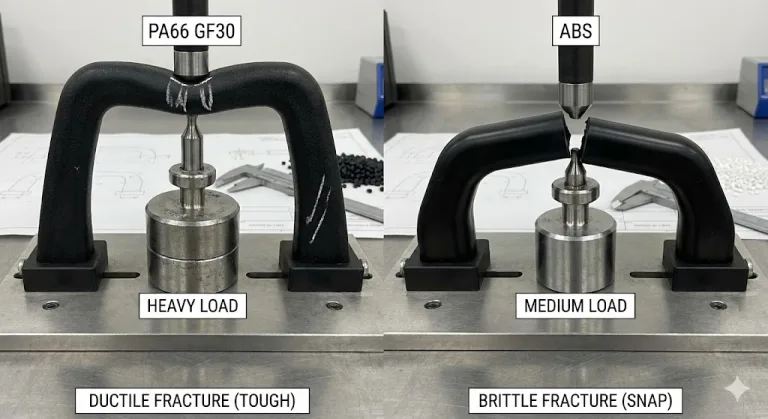

Strength & Durability

- Zinc Alloy: Moderate tensile strength (200–400 N/mm²). More prone to deformation or fatigue failure under heavy loads or frequent cycling.

- Stainless Steel: High tensile strength (520–750 N/mm²). Superior load-bearing capacity and fatigue resistance. Maintains stability over time.

- Real-World Impact: Zinc alloy hinges may loosen or break with frequent use. Stainless steel hinges ensure long-term reliability and safety in demanding applications.

| Material Category | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Elastic Modulus (GPa) | Density (g/cm³) |

|---|---|---|---|---|---|---|

| Zinc Alloy (Zamak 3 / 5) | 260 – 330 | 210 – 280 | 3 – 10 | 80 – 100 | ~83 | 6.6 – 6.7 |

| Aluminum Alloy (6061-T6) | ~310 | ~270 | 10 – 12 | ~95 | ~69 | 2.7 |

| Stainless Steel (304) | 520 – 750 | 210 – 310 | 40 – 60 | ~160 | ~193 | 7.9 |

Strength Comparison: Zinc Alloy vs. Stainless Steel

Corrosion Resistance & Environmental Suitability

| Material Category | Corrosion Mechanism | Suitable Environment | Outdoor Durability | Sensitivity to Humidity / Salt Spray | Coating / Maintenance Requirements | Recommended Applications |

|---|---|---|---|---|---|---|

| Zinc Alloy (Zamak 3 / 5) | Forms a protective zinc oxide layer | Dry indoor | Moderate | Corrodes easily in high humidity or salt spray | Relies on coatings; periodic maintenance required | Indoor, dry, low-corrosion environments |

| Stainless Steel (304 / 316) | Forms a protective chromium oxide layer | Indoor & outdoor, various environments | Excellent | Performs exceptionally well in high humidity, coastal, high-salt, or acidic/alkaline environments | Minimal maintenance required; 316 grade offers superior corrosion resistance | Outdoor or corrosive environments; high-durability requirements |

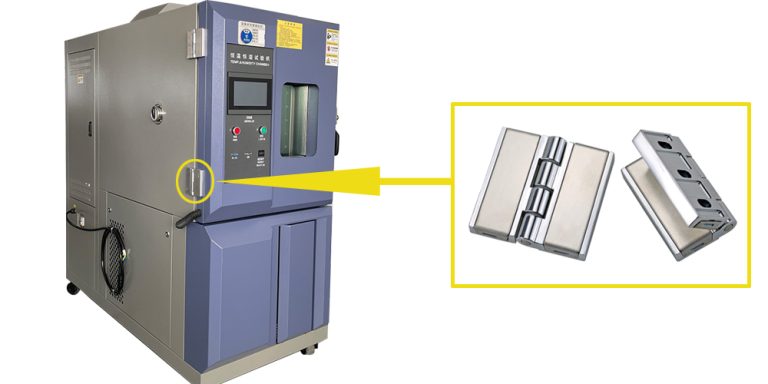

Heat & Fire Performance

| Material Category | Melting Point (°C) | Heat-Strength Retention | Max Service Temperature (°C) | Fire Resistance / Certification | Notes |

|---|---|---|---|---|---|

| Zinc Alloy (Zamak 3 / 5) | ~419.5 | Drops sharply above 200 | 150 – 200 (recommended) | Not suitable for high fire-rating applications | Not suitable for oven hinges or high-temperature environments; may melt or deform under heat |

| Stainless Steel (304) | 1,400 – 1,450 | Maintains strength at high temp | 800 – 1,000 (typical) | Can meet UL or fire safety certifications | Excellent heat resistance; stable in high-temperature industrial environments |

Weight & Installation Ease

- Zinc Alloy: Low density means lightweight hinges. Easier to handle, install, and transport. Reduces load on doors/cabinets. Good for weight-sensitive or movable items.

- Stainless Steel: Significantly heavier. Increases shipping costs and installation difficulty. Requires stronger support structures.

- Trade-off: Zinc alloy offers faster, easier installation. Stainless steel provides inherent stability but demands more effort.

Manufacturing & Cost Analysis

Manufacturing Processes

- Zinc Alloy: Primarily high-pressure die casting. Molten zinc injected rapidly into steel molds. Fast cycle times, high precision, high volume. Minimal waste for complex shapes. Requires post-processing (degating, cleaning) and surface finishing (plating, coating).

- Stainless Steel: More varied and complex processes. Stamping for standard hinges. Forging or casting for heavy-duty hinges. Machining, welding, assembly. Surface finishing includes grinding, polishing, passivation. Often requires no coating. Generally more manual steps and complex equipment.

Cost Structure

| Cost Category | Zinc Alloy (Zamak 3 / 5) | Stainless Steel (304 / 316) | Notes / Remarks |

|---|---|---|---|

| Material Cost | Much cheaper | Higher | Zinc alloy raw material cost significantly lower |

| Component Cost | ~30% less than equivalent stainless steel hinges | Baseline | Reflects typical hinge pricing differences |

| Tooling | Die-cast molds expensive but amortized over high volumes | Stamping molds cheaper, per-part processing cost higher | Economies of scale favor zinc in large production |

| Production Efficiency | High efficiency, lower defect rates | Moderate efficiency, higher defect risk | Zinc alloy casting is fast with fewer rejects |

| Long-Term Cost / TCO | May require more frequent replacement / maintenance | Longer lifespan, lower total cost of ownership | Stainless steel often better for long-term projects |

| Decision Tool | ROI and TCO models recommended to evaluate economic choice | Same | Consider production volume, lifespan, and maintenance |

Supply Chain & Procurement

- Zinc Alloy: Major producers often in lower-cost regions . Good for bulk purchasing. Focus on alloy grade and coating quality for the environment.

- Stainless Steel: Global suppliers. Reputed brands offer performance/service. Quality domestic options exist. Negotiate bulk/long-term contracts. Demand quality reports: material certs, salt spray tests, cycle life tests.

- Trends: Consider sustainability (recycled materials) and emerging tech (smart hinges with sensors/adjustment).

Application Scenarios & Summary

Zinc Alloy Hinges: Pros & Cons

- Pros: Low cost, easy to manufacture, diverse finishes via plating/coating. Good strength for medium loads. Lightweight.

- Cons: Limited load capacity. Poor performance in harsh environments/outdoors. Coatings can degrade, requiring maintenance. Shorter lifespan under stress. Not for safety doors or heavy industry.

- Best For: Cost-sensitive, light-to-medium duty, indoor use. E.g., internal cabinet doors, lightweight furniture, decorative panels.

Stainless Steel Hinges: Pros & Cons

- Pros: High strength, excellent corrosion resistance, very long lifespan. Minimal maintenance. High aesthetic appeal, scratch-resistant. Can handle very heavy loads (hundreds of kg/lbs).

- Cons: Higher initial cost. Heavier weight complicates shipping/installation. More difficult/energy-intensive to manufacture.

- Best For: Outdoor environments, heavy industrial equipment, chemical plants, marine applications, food/pharma, high-security doors. E.g., telecom base station cabinets, factory machinery, corrosive process areas.

Purchasing Guide & Key Decision Factors

Consider these factors when choosing hinges:

- Budget & Requirements: Define project budget and load needs. Zinc alloy for lower loads/cost sensitivity. Stainless steel for frequent use/heavy loads.

- Environment: Assess humidity, temperature, corrosion risks. Choose stainless steel (especially 316) for moisture, salt, chemicals. Zinc alloy is acceptable for dry, indoor use.

- Cycling Frequency: Opt for high-strength stainless steel hinges if doors are opened/closed very frequently. Reduces maintenance.

- Testing & Certification: Review quality reports. Key tests: Salt spray test hours (e.g., ASTM B117), fatigue cycle counts. Certifications validate claims.

- Supplier Quality: Choose reputable suppliers/brands. Check ISO certifications and after-sales support. Use tendering/long-term contracts for bulk purchases.

- Future Trends: Monitor smart hinges (auto-adjust, access control) and new sustainable materials. Stay informed for upgrades.

Conclusion

Zinc alloy and stainless steel hinges serve different purposes.

- Zinc Alloy: Focuses on economy and manufacturability. Best for light-duty indoor applications.

- Stainless Steel: Delivers high strength and corrosion resistance. Essential for heavy-duty or harsh environments.

Businesses must carefully weigh cost, performance, and durability against their specific needs. Consult with suppliers and engineers. Ensure your hinge choice delivers the best long-term value and return on investment.

FAQ

Q: What industrial equipment uses zinc alloy hinges?

A: Choose zinc alloy hinges for light-load, cost-sensitive applications. They work well for internal access panels, office furniture, and electronics enclosures in dry indoor conditions.

Q: Why do stainless steel hinges cost more?

A: Stainless steel hinges use high-cost chromium alloy and involve complex manufacturing. Their superior corrosion resistance and extended service life also justify the premium.

Q: How to distinguish zinc alloy from stainless steel hinges?

A: Check appearance and weight. Zinc alloy has plating and feels light; stainless is uncoated, heavier, and produces a clear metallic sound when tapped.

Q: How often should you replace cabinet hinges?

A: Stainless steel hinges often last decades. Zinc alloy may need replacement every few years under high use or in humid conditions.

Q: Do surface treatments boost zinc alloy hinge durability?

A: Yes. Electroplating or powder coating adds a protective layer. These coatings block moisture, reduce wear, and significantly extend hinge life.

-768x768.png)