HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Why Do Electrical Enclosures Need Specialized latches?

As an important safety barrier for control cabinets, distribution boxes and other equipment, the choice of cam latches has a direct impact on the effectiveness of equipment protection.

These cam latches are often found in industrial sites, open-air environments or humid and dusty areas, and must simultaneously achieve double protection: not only to prevent unauthorized opening to safeguard the internal circuitry, but also need to effectively isolate water vapor, dust and other environmental erosion.

While ordinary cam latches have limitations in terms of corrosion resistance, sealing performance and vandalism resistance, special cam latches can not only withstand violent prying and harsh environmental erosion through precise structural design and the application of reinforced materials, but also realize IP protection certification, ensuring the long-term reliable operation of electrical equipment in complex working conditions.

The Central Role of Cam latches in Electrical Enclosures

The cam latches realizes quick switching through a simple mechanical structure, and at the same time has the following functions:

- Security: prevents unauthorized operation or sabotage.

- Protection level: blocks water and dust from entering the interior of the enclosure.

- Ease of maintenance: can be installed or replaced without complicated tools.

Electrical Enclosure Cam latches Selection Points

When selecting cam latches, the following factors should be considered according to the actual use of the scene:

Security Level Requirements

- Is it necessary to prevent unauthorized operation? For example, a distribution box in a public place requires a high-security latches, while internal equipment may only need basic protection.

- Check that the latches are certified to industry standards.

Protection Class (IP Rating)

- IP65 and above: Suitable for outdoor, wet or dusty environments (e.g. construction sites, ports).

- IP54 and below: Suitable for dry indoor environments.

Mounting Method

- When space is limited: Select the mini type or cam latches that supports “quick release structure” and can be installed without tools.

- Standard installation: latches with nut fixing are more secure and suitable for scenes with high vibration.

Unlocking Method

- Key type: Individual key (unique for each latches) or universal key (one key for multiple latches).

- Other ways: some latches support press + rotate dual operation for higher security.

Material and Surface Treatment

- Corrosion resistance: stainless steel or plastic material is suitable for wet environment.

- Abrasion resistance: zinc alloy or metal material is more suitable for high-frequency switching scene.

- Cost control: Plastic latches are low in price but limited in strength.

Comparison of Recommended Cam latches Types and Advantages

According to different application scenarios, the following are four common electrical enclosure cam latches recommendations:

Quarter-turn Protection Cam latches

- Features: IP65 protection level, need to press the key and rotate to unlock, anti-misoperation design.

- Recommended scenarios: industrial control cabinets, outdoor distribution boxes.

- Advantages: waterproof and dustproof, anti-vibration, suitable for harsh environments.

T-Handle Cam latches

- Characteristics: Locked when handle is pressed, conforms to DIN EN 1774 standard, strong sealing.

- Recommended Scenario: Heavy duty electric control cabinet, outdoor switch box.

- Advantage: Easy to operate, strong compression force, suitable for equipment requiring high sealing.

45 Degree Mini Cam latches (with Spring)

- Features: Compact structure, spring provides continuous pressure, suitable for narrow space.

- Recommended scenarios: modular power distribution units, embedded control boxes.

- Advantages: Space saving, enhanced mechanical stability.

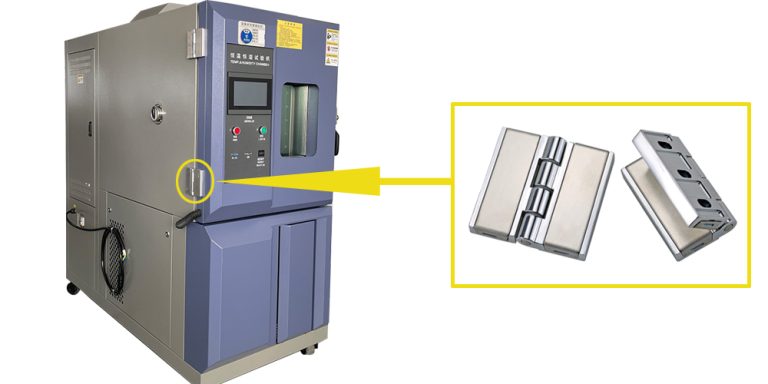

Plastic Threaded Cam latches

- Features: lightweight nylon material, IP65 rating, low cost.

- Recommended scenarios: temperature and humidity control boxes, low-risk equipment housings.

- Advantage: anti-corrosion, non-conductive, cost-effective.

Common Material Performance Comparison

When choosing the cam latches material, you need to balance the corrosion resistance, strength and cost:

| Material | Corrosion resistance | Strength | Cost | Applicable environment |

|---|---|---|---|---|

| Stainless steel | ★★★★★ | ★★★★★ | higher | Outdoor, high humidity, high corrosion environment |

| Zinc alloy | ★★★★☆ | ★★★★☆ | Moderate | General industrial locations |

| Nylon (30% glass fiber reinforced) | ★★★★☆☆ | ★★★★☆☆ | Low | Light duty indoor use |

| Zamack alloy | ★★★★★☆☆ | ★★★★☆ | Medium | Indoor use only |

Installation and Maintenance Recommendations

Installation Recommendations

- Choose cam latches with quick release structure or pre-assembled nuts to save installation time.

- For outdoor scenes, prioritize latches with sealing gaskets to ensure IP protection.

Maintenance Recommendations

- Quarterly check the latches body for looseness and the cam for wear.

- Clean the surface of thelatches regularly to avoid dust affecting the flexibility of the switch.

Conclusion:

Despite their small size, cam latches are a key component in the safety and security of electrical enclosures. Choosing the right type (e.g. quarter turn or T-handle latches), material (stainless steel or nylon) and degree of protection (IP65) according to the actual scenario can significantly extend the life of the equipment and reduce maintenance costs.

-768x768.png)

-768x768.png)